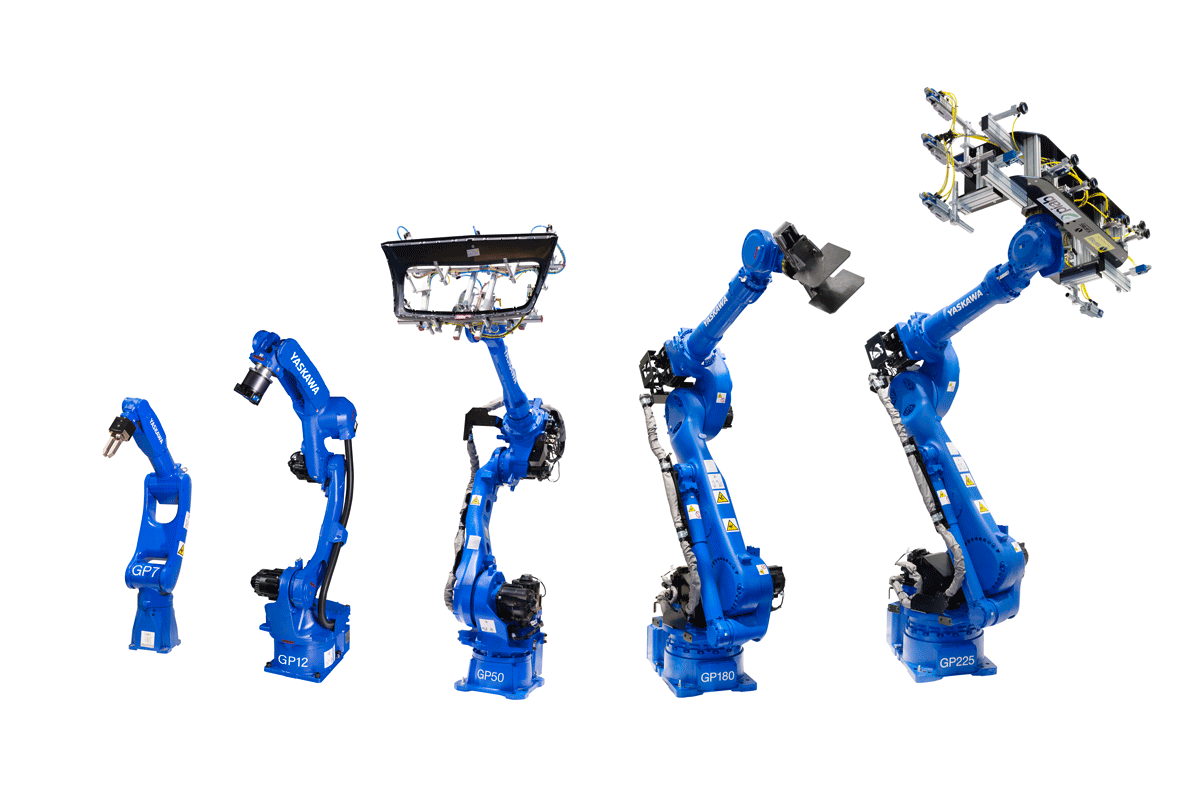

Yaskawa is one of the largest manufacturers of industrial robots in the world, providing specialised tools for welding, palletising, painting, and handling applications. “Yaskawa is a global company that delivers innovative solutions to the robotics sector,” says Andrew Crackett, Managing Director of Yaskawa Southern Africa. “In South Africa, the company serves as the EMEA leg into Africa from its head office in Johannesburg. Founded in 2012, we deliver tailor-made systems to customers that increase their performance and productivity in their sectors.”

The company has always focused on bespoke robotics solutions developed especially for its customers from its own manufactured products. This gives it an invaluable edge over competitors that primarily function as systems integrators.

However, recently the company has had to develop a solution to its own problem, when Yaskawa South Africa saw one of its branches submerged in water when heavy rainfall led to severe flooding and landslides in KwaZulu-Natal last year. It affected not just Yaskawa, but also Toyota, one of its major clients. The flooding was declared a state of national emergency, and for Crackett personally, it could not have come at a worse time.

“I first got the phone call when I was lying in bed suffering with Covid,” Crackett tells us. “I had to get over the initial Covid symptoms, then when I was able to get out of bed, I got myself to Durban and did a plant walk with the Toyota team, looking at the flooding on our equipment.”

While fortunately most of Yaskawa’s actual robots were above the waterline, its controllers were all completely submerged in water– and electronics and water do not mix.

“First we had to sort out our own facility before we could take on the workload from Toyota,” Crackett recalls.

Not in the Manual

Not in the Manual

The first job on the list was cleaning – a lot of cleaning.

“We brought in the cleaning crew to get the mud out and prepare the facility to receive components from Toyota,” Crackett says. “Then we stripped those components down to work on a repair solution.”

This was no simple task – electronics are never designed to be submerged in water and mud, and there is nothing in the manual about how to fix them when they are.

“There is no documented solution for how to repair flood-affected electronics,” Crackett says. “So, we put together a feasible plan, and sent the plan to Europe and Japan, where it was approved and that’s how we started.”

It was crucial to prioritise, as even Yaskawa’s facility was not big enough to support all of Toyota’s machinery in one go. The team had to determine which machinery was critical, and which could go to the back of the queue.

“A team of 25 guys from the UK, Germany and Japan came together to physically help us with the repairs. I was based in Durban from April to July, overseeing all the work, getting my hands dirty, literally,” Crackett tells us. “The amount of work was overwhelming, so we needed all the hands we could get.”

The biggest issue was not even the water. It was the mud.

“It was the fine silty, mud that rested inside all the electronic components. Breaking that down and getting the stuff clean was a nearly impossible task,” says Crackett. “We thought up the plan over breakfast. We cleaned off as much of the dirt as possible. We bought a whole bunch of dishwashers running at 40 degrees Celsius.”

Components were sent from there to a deep clean with a hypersonic bath – alcohol content with hypersonic vibrations. From there the parts went into a drying room – a tool room that had been converted with heaters, where it was left for 12 hours to dry.

“From there it went back to Assembly where we tested the components to get a failure versus pass rate,” Crackett says. “Surprisingly, we managed a 97% pass rate on equipment we salvaged.”

It was an experience that left Yaskawa, and its relationships with its clients stronger.

“We were happy with our efforts,” says Crackett. “Toyota were happy, and we made better relationships under the circumstances.”

The upshot is that while there might not have been a document before the facility was flooded, those documents certainly exist now – and given that flooding is a growing issue, it is fortunate that they have done the work.

The Next Level

The Next Level

To avoid that, Yaskawa South Africa has moved to a new branch facility, on higher ground, with more room for storage, demonstrations, and training.

“It really is a next-level facility for us,” Crackett tells us.

With the crisis passed, Crackett’s attention is on Yaskawa’s future in South Africa. Robotics is a rapidly moving sector and Crackett is committed to staying on the cutting edge of its development.

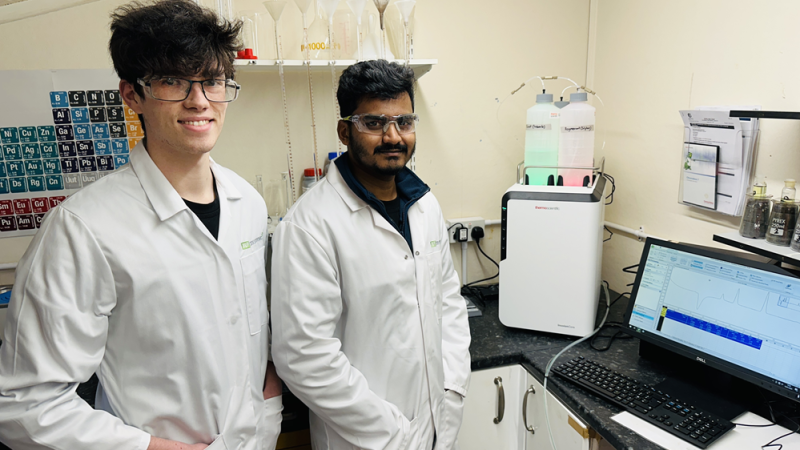

“We start with the critical component- we have a team with many years of experience,” he says. “These guys are a highly specialised team, and we keep them up to date on the technology while also making sure to keep the team happy. A happy team is a productive team. That is what we strive for.”

Those efforts to keep Yaskawa’s team happy are fundamental to the firm’s growth strategy.

“We are scaling the business as demand continues to grow, and that is essential to stay relevant as well as maintaining staff satisfaction,” Crackett points out. “We have Yaskawa’s Research and Development teams in Europe and Japan continually bringing us new products and ways of doing things to remain relevant to the manufacturing sector.”

The latest addition to Yaskawa’s technological repertoire is its i-Cube Mechatronics toolset. Yaskawa’s answer to Industry 4.0 is an integrated intelligent and innovative platform that will be a key driver for the company’s future.

As Crackett explains, “Our smart products enable the customer to gather real-time data and data analysis with AI learning, including information on predictable maintenance and machine wear. The intelligence component allows for big data analysis, offering new ways to optimise the production process at every level.”

It is the next step for Yaskawa, and Crackett is clearly excited about what it will bring to the company.

“We have an incredible future ahead,” he says. “We are at the forefront of warehouse applications, manufacturing solutions and human-robot collaborative offerings that really push the envelope.”