Packaging is not just about wrapping products in pretty paper or boxes; it plays a crucial role in the success of any business that produces, distributes, or sells products. It is the first point of contact between your customer and your product, influencing their purchasing decisions. But, the packaging is not without challenges. Business owners face several packaging-related issues, including increased labor costs, reduced efficiency, and quality issues. However, with technological advancements, packaging automation has emerged as a solution to these challenges. In this article, we will discuss the challenges related to packaging and explore the reasons why business owners should automate their packaging and how it can benefit their business.

Labor Cost

One of the biggest challenges is labor costs. Manual packaging processes require significant manual labor, which can be time-consuming and labor-intensive. This can result in increased labor costs, as businesses must hire more workers or require their current staff to work longer hours to keep up with demand.

Errors

Additionally, manual packaging processes are prone to errors, which can further increase costs due to product waste or rework. This is because manual processes rely on human operators to perform tasks, and humans are capable. Errors can occur when operators misplace or damage products, use faulty materials or quantities, or fail to follow proper procedures.

Efficiency

Another challenge is reduced efficiency. Manual packaging processes can be slow and inefficient, which can lead to delays in shipping and customer dissatisfaction. This is because manual processes require a significant amount of time to complete, and they may not be able to keep up with the demands of modern commerce.

Quality issues

Finally, manual packaging processes can result in inconsistencies and errors, which can lead to product damage or defects. This is because manual processes need to be able to consistently apply the correct amount of pressure, use suitable materials, or maintain a consistent temperature or humidity level.

Are you tired of the laborious and time-consuming process of packaging your products, and do you want to improve the quality and consistency of your packaging while reducing labor costs? Then it’s time to consider packaging automation!

What is Packaging Automation?

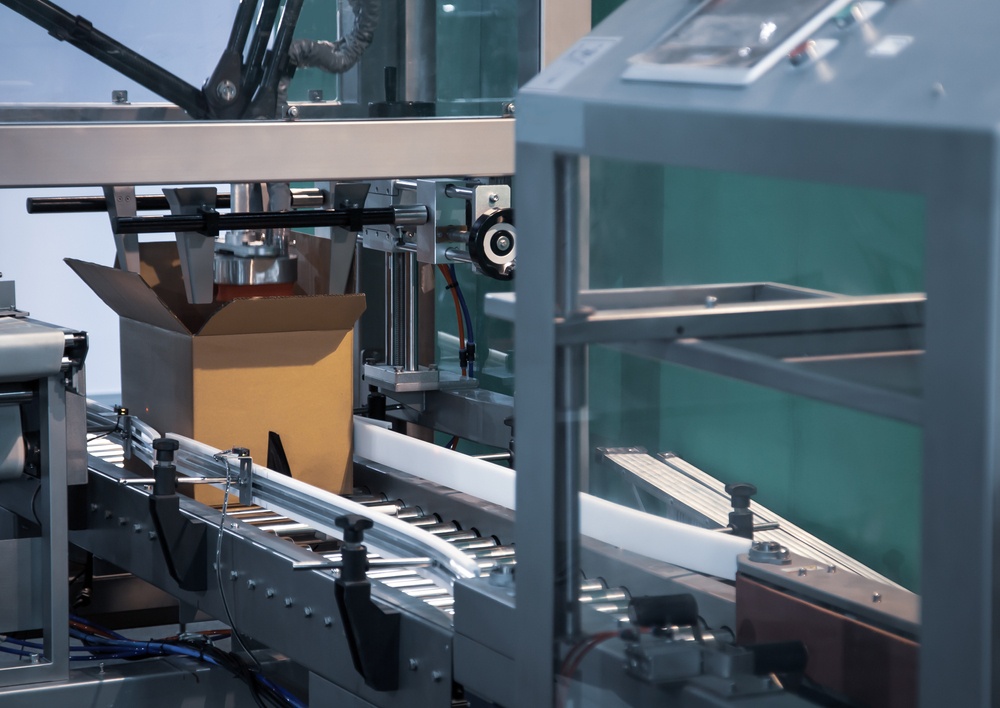

Packaging automation is the use of technology to streamline the packaging process, from product handling to final packaging. It involves using machines to perform tasks traditionally done manually, such as folding, sealing, labeling, and palletizing. Technology has evolved over the years, and today, businesses can use several packaging automation solutions to improve their packaging processes. Examples include case erectors, cartoners, palletizers, stretch wrappers, and labeling machines.

What are the benefits of packaging automation?

The benefits of packaging automation are numerous. First, it improves efficiency and productivity by reducing the need for manual labor, and this can significantly reduce labor costs and improve overall production output.

Second, packaging automation improves the quality of packaging by ensuring that products are packaged consistently and accurately. This reduces the risk of errors and ensures that products are protected during transit.

Third, packaging automation enhances safety by reducing the risk of injury from manual labor. This is particularly important in industries where heavy lifting or repetitive motions are involved.

Fourth, packaging automation provides flexibility and customization, allowing businesses to tailor their packaging processes to their needs. This can improve the overall customer experience and lead to increased customer satisfaction.

Fifth, packaging automation improves sustainability by reducing waste and promoting eco-friendly packaging practices. This is an important consideration for businesses that want to improve their environmental impact and meet regulatory requirements.

However, implementing automation requires careful planning and consideration. Businesses must assess their packaging needs and identify areas where automation can be implemented. They must also consider the costs of automation, including equipment, maintenance, and training. While packaging automation can provide significant benefits, it is essential to ensure that the investment is feasible and aligned with the business’s goals and objectives.

In Conclusion

Packaging automation has emerged as a solution to the challenges faced by businesses in the packaging industry. It provides numerous benefits, including improved efficiency, quality, safety, flexibility, and sustainability. With technological advancements, several packaging automation solutions are available, including case erectors, cartoners, palletizers, stretch wrappers, and labeling machines. However, implementing automation requires careful planning and consideration to ensure that the investment is feasible and aligned with the business’s goals and objectives.

By adopting automation, businesses can improve their packaging processes and gain a competitive advantage in the market!