Logistex’ operations are primarily focused on the UK but also serves customers in Antwerp, Barcelona, and Denmark, providing automation solutions to customers including Procter & Gamble, Coca-Cola, Britvic, John Lewis, B&Q, JCB, Superdrug, and BT. It has also undertaken electromechanical work with Amazon.

“We provide turnkey solutions for the complete lifecycle of a warehouse automation project,” explains Tony Gruber, Managing Director of Logistex.

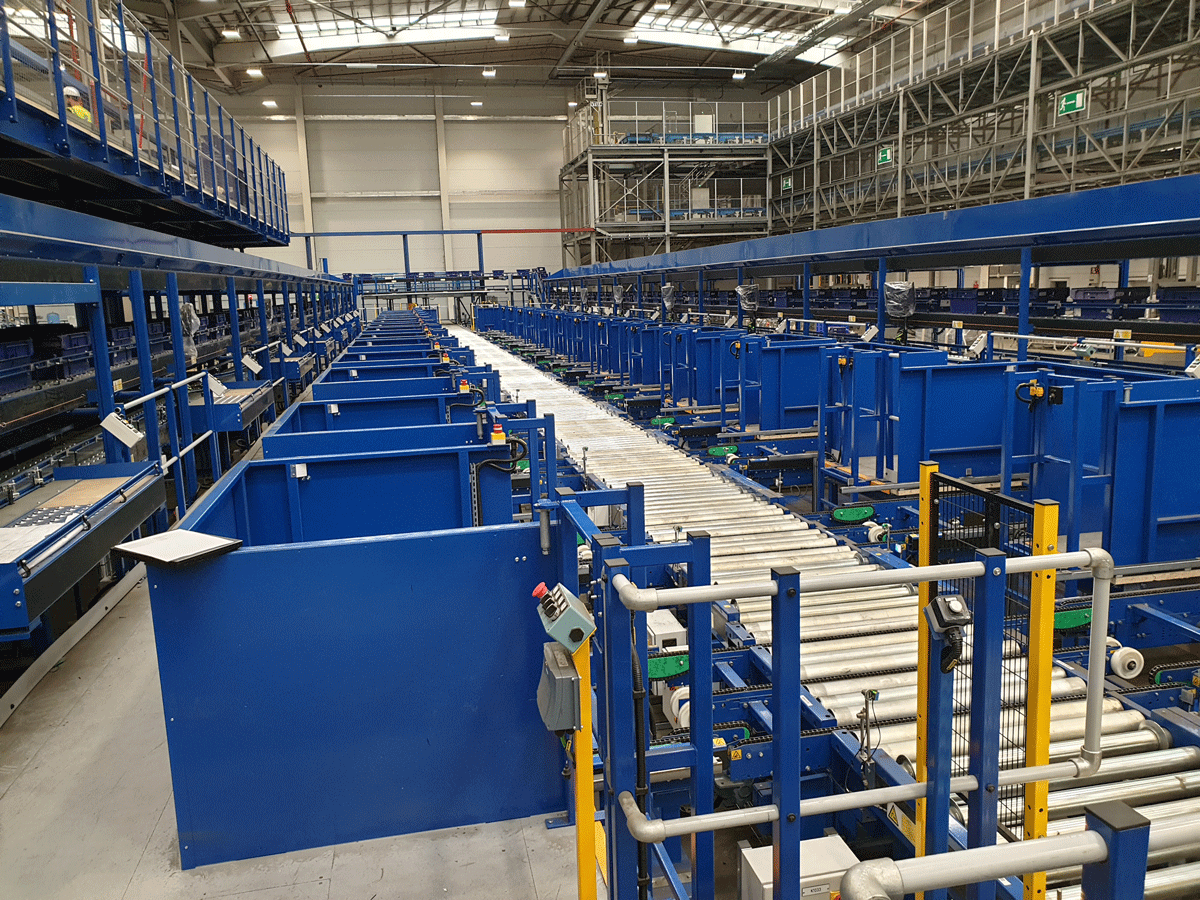

Logistex offers detailed engineering design, software development, mechanical and electrical installation, project management, commissioning, integration, testing, and handover, followed by on-site support and 24/7 software support alongside software and hardware upgrades as required.

The business works across two areas. The first is the projects side of the business that wins, designs, implements, and successfully delivers projects. Then there is the engineering support services side of the business. That is where the software, electrical and mechanical engineers support Logistex’s customers through residential, field service and hotline contracts for automation and software support.

An Independent Systems Integrator

An Independent Systems Integrator

Logistex started life as a manufacturer of automation systems, but since the noughties, the company sourced its equipment from other business partners.

“It means that we have access to the factories without having to keep the factories busy,” Gruber explains. “Having a factory, you always have to feed the beast, which comes with significant overheads.”

Today Logistex is an independent systems integrator, with only one product, its software package that combines the Reflex Warehouse Execution System (WES) and the reporting tool Analytex.

“We are not tied to a specific manufacturer for equipment, so we can select the best in class from different manufacturers and integrate it with Reflex for the best automated solution,” explains Gruber. “We have a proven track record of integrating different technology into the Reflex product over the years. We have modified it to work with other suppliers’ mini loads, A-frames, tote & pallet shuttle systems and now we have signed our first contracts for AMRs, autonomous mobile robots.”

This a landmark achievement for Logistex, as the first order for new technology is always difficult.

“Customers want a relevant reference site,” Gruber points out. “Fortunately, we were able to generate that confidence through our track record. Integrating new technologies is what we do. We are also flexible in the functionality that we supply. We find all of our customers want some bespoke functionality that is unique to them.”

To deliver that bespoke functionality without a manufacturing base of its own, Logistex needs to maintain strong relationships with its supply chain.

“We are very much a relationship-driven business. We rely on long-term relationships with our colleagues, suppliers, and customers,” Gruber says. “50% of our turnover is through support contracts post-go-live. Our longest-running site has been supported for over 30 years.”

Without their own manufacturing, Logistex needs to source materials handling equipment at the right price to compete effectively in the marketplace. Fortunately, Logistex has established strategic partnerships with key manufacturers.

“We don’t want to buy at the market rate and add our margin on top,” Gruber says.

Logistex’s strategic partners include Savoye in France, who have supplied a number of X-PTS tote shuttle systems plus carton erectors and carton closers, and the Italian firm, Automha who provide a pallet shuttle system Logistex has installed at several sites. More recently, Logistex has made use of Cornerstone Automation in the US, which provides an intelligent prescription processing machine.

Employee-Owned

Employee-Owned

As valuable as Logistex’s track record and flexibility are, however, the nature of the business itself has also proven to be a powerful unique selling point.

“We are an employee-owned trust. When you interact with one of our colleagues you are talking to someone who earns a share of the profits of the business. That makes a difference,” Gruber says.

It might seem counter-intuitive for an employee-owned and led company to work in the automation sector, which is widely seen as making employees obsolete. But in the current labour environment, Gruber argues, automation is a tool that serves workers’ interests.

“There are real pressures on our customers to actually find enough staff to make their operation viable,” Gruber says. “What we are seeing is that because of the pandemic, because of Brexit, there is just not the labour out there. From an employee perspective that is great, because there is now significant wage inflation to attract talent from the smaller pool available. The return on that investment can be improved through automation.”

Rather than replacing workers, Gruber argues that automation improves their conditions. In a sector where manual operations will see staff pushing around a trolley, walking in excess of 10 to 15km.

“There are reports of people working up on the top level of a mezzanine floor, in 30 degrees, and people fainting,” Gruber says. “The automation we are putting in place replaces that manual pick walk.”

While Logistex’s people are very much at the centre of every decision it makes, in a literal sense those people can be flung far afield, which brings its own challenges.

“Having a single unified culture where so many of our staff are at customer sites is challenging,” Gruber admits. “We have local people based on site and it is easy for them to feel more like a part of the customer team than our own.”

This was exacerbated during the pandemic when Logistex could not visit its on-site staff, relying on email and virtual meetings.

“Now Wednesdays are for physical site visits to go around and see the site teams,” Gruber insists. “I know it sounds trite to say people are our best assets, but we have one product, software, so people are our only asset.”

Perhaps that attitude is best demonstrated in the “Just Culture” attitude Logistex has borrowed from the aviation industry.

“The idea is that every accident or incident is a learning opportunity rather than something where blame needs to be apportioned,” Gruber says. “Someone who has a near-miss no one else knows about can self-report to allow us to find the root cause and prevent a future accident. That requires a significant level of trust because the self-reporter can feel that they are placing themselves in a vulnerable position.”

Among the Elephants

Automation allows smaller companies to have bigger leverage, and that is something Logistex knows a lot about.

“Elephants like to play with elephants. As a private company, we sometimes feel constrained by the size of our balance sheet. You do not get sacked for hiring IBM,” Gruber points out. “But the feedback I have had from customers is that we are more responsive. All our design and development colleagues are based in the UK, whereas our Tier One competitors are based in continental Europe. We like to think of ourselves as big enough to matter but small enough to care.”

Logistex will continue to care, but it may not be small for long. Gruber’s vision is for the firm to become the largest in its class of providers of integrated robotic warehouse solutions in the UK.

“We hear a lot about robotic picking systems. But if a product is delivered to the site in a palletised form it must then go through a decanting system, be transferred to totes for the robotic picking system, then the picked-to-order totes might need to be conveyed to consolidation and a packing zone before being dispatched,” Gruber points out. “This is where we really add value. Robot companies cannot provide an end-to-end solution. They need a systems integrator.”