It has been two years since we spoke with BDD, the experts in biopharmaceutics, oral drug formulation, gamma scintigraphy and Phase I clinical trials. The company has a celebrated reputation as an integrated drug development, delivery and clinical trials company. It is a trusted partner in the process of taking a new product from a white powder, through formulation development and clinical testing, and it carries out all of these functions in-house.

It is a reputation that the company is proud of, but BDD’s CEO, Dr Carol Thomson, is already working towards the company’s next big goal.

Putting it simply, she tells us, “We are looking to disrupt the way that early phase clinical testing is carried out to support faster and more streamlined advancement of new therapies.”

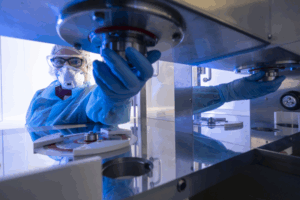

For the last two years, BDD has been focused on expanding its pioneering Lean Clinical Development™ pathway, to cover the entire early phase clinical development stages. That encompasses early-stage formulation, GMP manufacture, and rapid clinical testing, including first-in-human studies. The company is also working towards the gold standard MHRA accreditation for Phase I clinical trials. Using recent investments, BDD has also built a new GMP suite that has expanded its manufacturing capabilities and allows for the production and release of larger batches of clinical trial supplies.

“Lean Clinical Development™ sets us apart and makes us unique,” says Calum Stevens, BDD’s Commercial Director. “It is essentially about cutting waste from the old way of doing things. We offer a single point solution to get phase I clinical data faster by eliminating unnecessary steps and our clients are really positive about it.”

Lowering the Threshold

The new GMP facility is a perfect example of this. It is not just about increasing production capacity, but enabling phase appropriate batch manufacturing so that BDD can produce exactly the amount needed, tailored to the testing requirements of the client and the stage of development that they are at. This, combined with rapid in-parallel formulating, drastically reduces the initial investment needed to begin human testing for a new pharmaceutical product.

“We developed Lean Clinical Development™ to support smaller innovative biotech companies; when you only have a small amount of investment, it means you cherish every dollar,” Stevens says. “Our facilities mean we do not have to manufacture unnecessarily large volumes for a small-scale clinical proof of concept, and we can offer that on a rapid timescale. We get clients through that early stage of development in the quickest, least wasteful way possible. That is why people are excited by what we’re doing. We’re at the forefront of lean, ‘just-in-time’ delivery for clinical development.”

This is possible because of the unique way BDD integrates small scale manufacture and early human testing. Unlike traditional clinical trials, its model is based on extremely rapid testing on sample sizes of as few as eight to twelve volunteers or patients to provide the proof-of-concept needed for further testing and to help secure further investment.

By lowering the investment threshold for delivering new medicines, BDD opens the door to a whole new world of innovation in the pharmaceutical space. It is a valuable tool for new entrants to the market, but that is not all.

“Originally, we thought it would be a game changer for smaller companies that needed to prove their product idea works,” Thomson recalls. “The initial investment for a new pharmaceutical product used to be quite significant, and that was a barrier to entry for smaller companies. It meant that some really clever science wasn’t coming to market.”

By scaling the process down and enabling rapid confirmatory clinical trials, BDD gives these businesses the opportunity to attract new investment and quickly take their project to the next stage. What surprised Thomson was how appealing this was to larger and more established presences in the pharmaceutical sector as well.

With big pharmaceutical companies, there is often pressure to stick with ‘safer’ products, while more innovative, but riskier projects that may require greater investment are left on the back burner.

“They want to take on more innovative projects and we allow them to de-risk that process,” Thomson says.

Pioneers of the Sector

As well as leading the way for Lean Clinical Development™, and refining those processes to yield ever greater results, BDD has also become a pioneer in mucociliary clearance and respiratory studies, testing new propellants for inhalers using gamma scintigraphy.

“Global regulations are moving away from the current propellants used in pressurised inhalers, which are bad for the environment,” Thomson informs us. “We have become world leaders in carrying out studies to test the impact of new ‘Low Global Warming’ propellants on lung function and we are proud to play a part in that sustainability journey.”

BDD has achieved all this while navigating industry-wide economic challenges and has continued growing year-on-year. As the company has grown, naturally its staff have grown with it, and as it celebrates its 25th anniversary, BDD is proud to maintain its core values, ‘working to the highest quality with uncompromising honesty, transparency and integrity.’

“We have made significant hires that have been game-changing for us, and I am confident we have the strongest team we’ve ever had, which provides me with a great deal of confidence as we continue to scale,” Thomson shares.

BDD’s new hires ensure excellence in leadership across our broad range of services. Their teams work closely together to ensure a seamless progression through formulation development, GMP manufacture and clinical testing. With projects run under a single contract, with one dedicated project manager, BDD ensures that the product knowledge gained at the early stage is captured through the entire project.

That talent acquisition is taking place alongside a sustained drive by Laura Gow, BDD’s COO, to make BDD a great place to work.

“It’s one of the three pillars we stand by,” Thomson tells us. “Our mission is to be scientists, enjoy doing the science, and fix the most challenging problems. But we also want to have fun while we are doing it. Every day we learn something new as a team. Being somewhere people want to work and learn has allowed us to recruit some of the best.”

As it goes into its 25th year, the company’s message remains that it is changing the way things are done in the pharmaceutical sector.

“Our vision has always been the same,” Thomson says. “To be the go-to company for accelerating product development. We are all scientists. A significant majority of our staff are science graduates with advanced degrees, and we put our heart and soul into these projects. Because we do the clinical analysis and formulation, we have learned what happens when you put products into people. Using this knowledge, we can design products to work in the human body, achieving success, fast. That is why people come to us with their most valuable, most challenging and innovative projects.”