With more than 140 years of history, Tarkett is a worldwide leader in innovative and sustainable flooring and sports surface solutions, generating turnover of € 3.3 billion in 2024. The Group has close to 12,000 employees, 24 R&D centers, 8 recycling centers and 35 production sites around the world. Tarkett creates and manufactures solutions for hospitals, schools, hotels, offices, stores and sports fields as well as for residential users, serving customers in over 100 countries.

Tarkett has one of the widest and largest portfolios of products and solutions in the flooring industry, catering to diverse customer needs, enhancing the health and well-being of building users with a strong focus on minimising environmental impact.

Climate change and the circular economy are major topics at Tarkett, and as a supplier to the building and construction industry, which is a significant producer of waste on a global scale, the company has set out to make a difference.

“As a leading flooring manufacturer, we have a significant opportunity and responsibility to create change in our industry. Our commitment to sustainability is also our key differentiator,” says Thomas Leneveu, Vice-President of Tarkett Business Unit Commercial Flooring.

“With a century of experience and know-how, we offer products that are highly advanced from a technical point of view. However, at the same time, we create products with circularity in mind.”

Closing the loop

Closing the loop

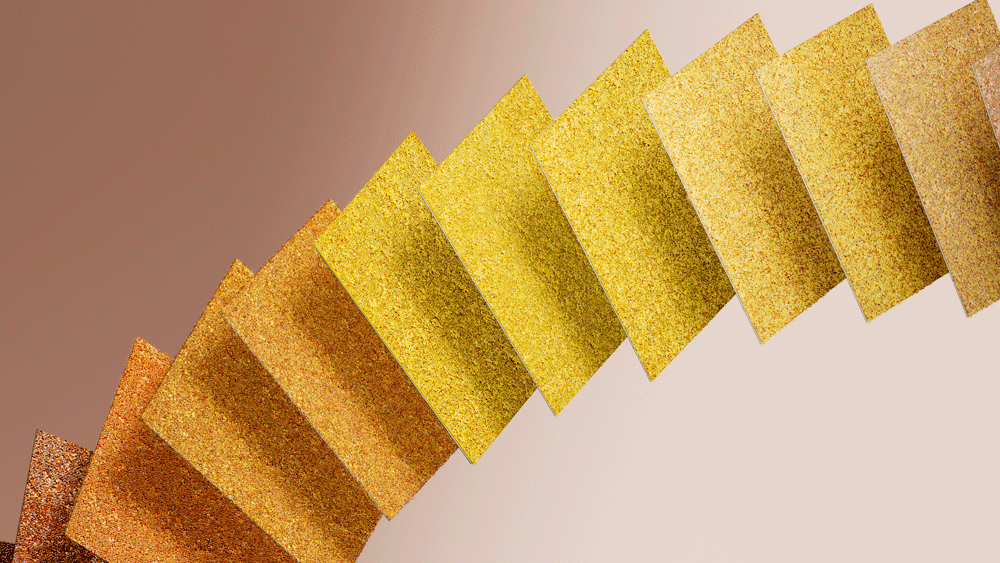

Tarkett’s latest milestone is the evolution of DESSO EcoBase® backing — by incorporating a bio-based ingredient from a new cross-industry partnership, the company has achieved its lowest circular carbon footprint yet, continuing to demonstrate its dedication to circularity.

Leneveu describes how at a Cradle-to-Cradle event at the company site in the Netherlands, the director of a local water company revealed he had calcium carbonate (chalk) residues available, which could help DESSO’s ongoing search for defined recycled materials, replacing virgin chalk supplied from a mine in Northern France.

Working with AquaMinerals a Dutch drinking water industry partnership, Tarkett’s engineers achieve the exact composition and size of chalk particles needed for the EcoBase backing and manufacturing processes, using chalk from a number of local water treatment plants.

In addition, a long-term, close collaboration with Aquafil, a leading producer of PA6 yarn, opened up a way to recycle the PA6 yarn from DESSO carpet tiles into new carpet yarns. This major step forward meant that both yarn and EcoBase backing could now be disassembled and recycled into resources for the next carpet cycle – making DESSO the only carpet maker in Europe to have externally verified evidence of closing the loop on carpet tile production.

“Suppliers are a critical part of the process and in many cases play a key role, directly or indirectly, in the ecosystem. Partnerships with suppliers like Aquafil are indispensable in our efforts towards circularity,” affirms Leneveu.

Tarkett’s efforts have been duly recognised – just recently, the company achieved Platinum Level at EcoVadis, the renowned sustainability rating platform, thus joining the top 1% of the 130,000+ companies assessed by EcoVadis across 180 countries as the only multi-product company in the flooring and sports surfaces industry.

Core pillars of circularity

Leneveu explains that Tarkett’s sustainability strategy in EMEA, ‘The Beauty of Circularity,” is built on three pillars: design, materials and the circular journey. “Circularity starts with design. Designing the products for circularity covers choosing the right materials and ensuring you have the system in place to take back and recycle the products.”

Tarkett carefully selects materials to improve indoor health and reduce environmental impact. “We make a full assessment of any raw material, according to Cradle-to-Cradle principles. We select positively assessed raw materials in our product, and we always investigate alternatives to the use of virgin material.”

The company prioritizes recycled and bio-based materials, such as replacing petroleum-based components in carpet tiles with bio-based alternatives sourced locally in Europe. These initiatives align with Tarkett’s goal to achieve 30% recycled content across its products by 2030.

Within the circular journey, Tarkett collaborates with customers, suppliers, and industry associations, building robust systems to close the material loop.

Taking full responsibility for the full life cycle of its products, the company has introduced a pioneering take-back and recycling programme, ReStart®.

The programme, now operating in 29 countries across the world, collects end-of-life products across Europe, enabling efficient recycling and ensures more post-installation and used flooring avoids landfill and incineration.

A new flagship product underscoring this approach is IQ Loop, a homogeneous vinyl flooring that contains at least 65% post-use recycled content. The product is fully recyclable, even post-use, and has the lowest life-cycle cost on the market.

As IQ Loop consists mainly of post-consumer material, the collection is primarily offered to those customers who contribute material, incentivising those who recycle their post-consumer waste to join the loop.

Driving systematic change within the industry

Driving systematic change within the industry

Tarkett championed circular economy principles long before they became mainstream. In Sweden, the company began recycling homogeneous vinyl floors as early as 1957, and over the last decade has further enhanced the Cradle-to-Cradle methodologies, in line with customers’ growing interest in eco-products.

Speaking about general market developments, Leneveu admits that the most pressing challenge is time. The building industry’s substantial environmental footprint presents significant challenges, underscoring the urgency of sustainable practices.

“Our primary challenge lies in accelerating the pace of change. Establishing recycling ecosystems and influencing regulatory frameworks are time-intensive processes, so expediting progress is an important task, to be achieved with all stakeholders.”

He affirms that a further improved circular carbon footprint will remain the core objective for the future. “For Tarkett it’s not about producing more, but better. To this end, Tarkett will focus on enhancing its sustainability credentials, investing in recycling infrastructure as well as R&D, aiming to increase recycled content in products and improve material performance.”

In concluding, he affirms that success cannot be achieved in isolation: “In order to achieve a future in which people and planet can flourish, we must place collaboration at the core. Circularity is a collective effort, and collaboration is fundamental to enable materials to be returned to make into new products. We invite our community to Join the Loop.”

For more information: www.tarkett.com