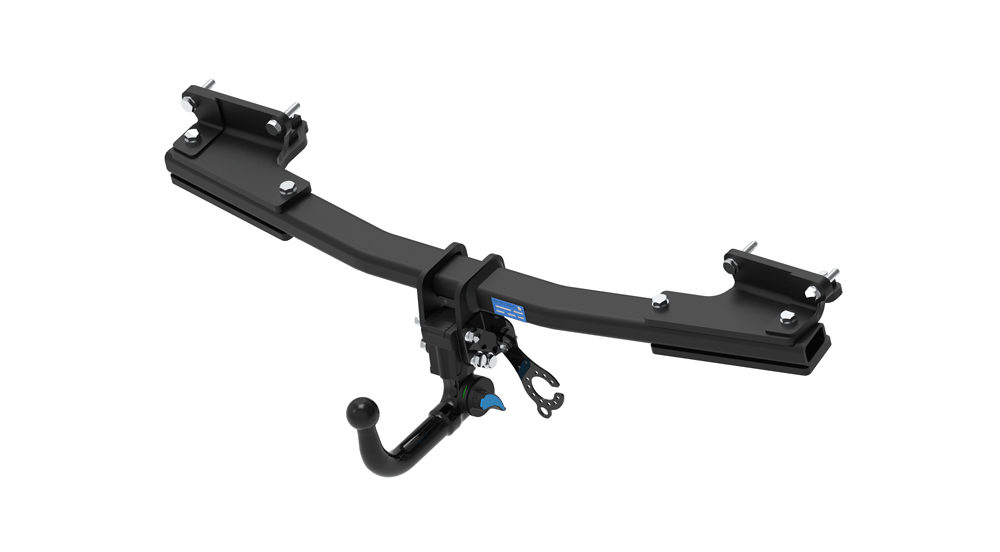

Tow Trust Towbars Ltd is the UK’s largest manufacturer of tow bars, rear under-run protection devices (PRO-TECT), rear access solution steps (PRO-STEP) and towing accessories. Based in Atherstone, Warwickshire, the company has deliberately positioned itself at the premium end of the market – sourcing the finest quality steel and using the latest technology in its design, testing and manufacturing processes, in order to supply the highest quality products.

When we interviewed Tom Miller, the CEO of Tow Trust Towbars, last year, he spoke about how his parents started the business from scratch in a garage and developed the company to become the market leader in its sector. He also described the attributes that have made the business thrive – the pride and passion of a family-owned business, the outstanding level of service and close relationships with customers.

This ethos continues to drive the company forward – with a record-breaking year in 2024 and a 13% growth rate, Tow Trust has launched industry-leading innovations, following a period of stabilisation, and is set to further increase its market share.

At the forefront of innovation

At the forefront of innovation

Tom Miller explains: “Responding to the growth in the motorhome market, we have invested in this segment and launched the UK’s first fully type-approved, UK-designed and manufactured motorhome chassis for the aftermarket. We have tried to put our decades of experience into what we believe to be the most diverse chassis on the market, eliminating extra work for the fitter, maximising strength, whilst still looking fantastic when fitted, only complementing the motorhome it is fitted to.”

He further says that Tow Trust has also created an extensive range of tow bars that can be used in conjunction with the chassis all while staying fully type approved, as well as unique accessories including floor supports and strengthening corner braces. “We now plan to try and get the chassis into the OEM world, supplying the world’s largest motorhome manufacturers. We already have Erwin Hymer UK using one of the chassis designs with remarkable success,” he adds.

Another exciting development is Tow Trust’s expansion into vehicle-specific wiring kits. Miller points out that while these kits have existed for over a decade, adoption of them has been slow.” With the developments in vehicle technology over recent years, almost all modern vehicles will require a vehicle specific wiring kit due to the safety systems built within the vehicle. Vehicle specific wiring kits work in harmony with these systems, making the towing experience as safe as possible and being used in the way the vehicle manufacturer intended. We see this as a huge growth sector.”

“Tow Trust has always tried to be at the forefront of technology, and we plan to invest heavily in the sector, working closely with our partner Conwys, stocking a large range of kits that cover all vehicles on the road, and training our staff to be the best they can be regarding installation and technical knowledge,” Miller says, adding that the company hopes to be the largest supplier of vehicle specific wiring kits within the next few years, and has chosen who it believes to be the best in the world at it – Conwys.

Investing in technology and people

Tow Trust’s success isn’t just about new products; it’s about how they are made. Continual upgrades to plant machinery results in better products and better processes, and in this respect Miller highlights a close relationship with Bystronic, which has provided some 70% of machines that create Tow-Trust’s wonderful product range, including state-of-the-art sheet steel fibre lasers and 3D controlled 6-axis press brakes, and hollow section fibre lasers. Tow-Trust are also working closely with Bystronic for further automated machines to complement their current production methods.

To further enhance its production capability, the company is currently undertaking a £2 million investment programme to upgrade and expand its manufacturing plant. This will include advanced laser and automation systems, welding robots and the latest scanning technology that will overlay real-life product scans with CAD designs, removing human error and ensuring flawless results.

“This is a major investment for us, which will catapult us forward through 2025. Still, our success is not built just on advanced technologies but primarily on our committed people,” Miller says, stressing that the company has embraced a forward-thinking approach to workforce development, offering training opportunities for employees of all ages. Apprenticeships aren’t limited to younger workers; individuals in their 30s, 40s, and even 50s are taking advantage of these programmes.

“These initiatives are about more than just upskilling; they foster a culture of continuous improvement and add value not only to the employees but also to the company. It’s about creating a workforce that’s skilled, motivated, and ready to tackle future challenges,” says Miller.

Additionally, Tow Trust is in the preliminary stages of setting up a partnership with Birmingham University for a knowledge transfer programme, pairing students with the company to work on meaningful projects. This collaboration not only enhances innovation but also creates a talent pipeline for the future.

The road ahead

The road ahead

The implementation of new machinery and workflows will undoubtedly bring challenges, but Miller approaches them with a positive mindset. “My father taught me that there is no such thing as a problem in business, only beautifully disguised opportunities. I’ve learned to embrace challenges and even enjoy them.”

With regard to its wider ecosystem, he points out that the company considers its suppliers as partners, working closely to ensure that their performance matches Tow Trust’s high standards. “The suppliers’ performance determines the performance of my company. Tow Trust couldn’t be the best if its suppliers weren’t the best. If they want to be part of our journey, my team will collaborate with their team to make sure that we are on the same wavelength.”

By sourcing materials locally, the company minimizes transportation emissions and supports regional economies. Most subcontractors are located within 20 to 30 miles of Tow Trust’s headquarters in the Midlands, significantly reducing their combined carbon footprint.

Looking ahead, Miller says that by Q1 of 2025, the £2 million investment will go full steam ahead. “After a short period of training and stabilisation again, Tow Trust will be ready for serious business. ”

“We are ready to tackle the challenges ahead and continue to offer the industry a better level of service with higher quality products. Continuous improvement and investment will always be at the heart of Tow Trust,” says Miller, who is very passionate about his business, an aspect clearly mirrored in the business growth.

He affirms that the focus for the coming years will be on growing the tow bar, motorhome chassis and vehicle-specific wiring kit product lines, which are expected to drive significant growth. By supporting its commitment to quality, innovation, and customer service, Tow Trust aims to set new benchmarks for the industry.