There are international companies. Then there are companies that claim to have a presence on every continent. Finally, there is the vanishingly small number of companies whose products can actually be found on every continent. Deeter Electronics is one of those precious few companies with a presence that is truly global – and more. It is a leading float switch and liquid level sensor supplier based in the UK, providing a range of bespoke ATEX & IECEx-certified sensors across the planet and into the aerospace sector.

“We have sold sensors on every continent, including Antarctica!” says Joseph Whiteaker, Managing Director of Deeter Electronics. “We even have some in space, and on the way to Saturn.”

Deeter Electronics is a family-owned electronics and engineering company that specialises in liquid level sensors and control equipment. Its story began 40 years ago in the garden shed of the company’s founder, Peter Whiteaker, Joseph Whiteaker’s father. From there the company has grown to achieve the more-than-global reach that it has today, but even now it remains a proudly British company.

“We design and manufacture everything here in the UK,” Whiteaker tells us. “We are an agile company that provides quality, bespoke sensors to meet our customers’ needs. 70% of the products we sell are designed and made on demand.”

Deeter’s sensors have found use not just on every continent, but in every sector. They can be found in public transport, energy storage, or even in a garden pond. Equipment designed and built by Deeter Electronics can be found in laboratories at the Covid laboratory at AstraZeneca. But most of all, Deeter has specialised in providing sensors for hazardous areas, including deep space.

Currently, the firm is looking forward to the launch of a probe to Saturn in 2028. One of Deeter’s sensors will be used to measure the liquid nitrogen levels that in turn will cool the camera used to photograph Saturn’s surface.

“That’s being sent to Saturn next year,” Whiteaker says. “We are into all kinds of weird and wonderful projects like that. We have worked with Formula One cars and nuclear submarines.”

Staying Fluid

Staying Fluid

Working across such a wide range of sectors demands an exceptional degree of flexibility, a degree of flexibility that Deeter Electronics is more than equipped to provide.

“We are able to respond to customer needs quickly,” Whiteaker says. “That is where we have built our niche. We can make a single bespoke sensor, or provide a product run of thousands.”

That flexibility has been essential to the company’s survival over the last 42 years, which have included multiple economic crises and a major pandemic. Historically, Deeter has responded to downturns in the market by using them as an opportunity to retool.

“We design and manufacture everything here, so when things slow down we design new products,” Whiteaker tells us. “The people who sit still are the ones who fall behind, so we are always pushing. During the pandemic, we built a new line of liquid sensors for the Liquid Natural Gas sector as it was becoming far more prominent. We are a close-knit family of people here, so we battened down the hatches and focused on developing a whole new line of sensors to release on the other side of the crisis.”

Deeter Electronics’ ability to solve problems is what has set the firm apart in the industry. Clients come to the company with a liquid that needs a sensor, and usually a challenge that makes installing that sensor difficult.

“We design sensors for all sorts of challenges. Those are our day-to-day challenges,” Whiteaker says. “70% of the business we get is bespoke. People come to us when they don’t have a solution, and we help them design one.”

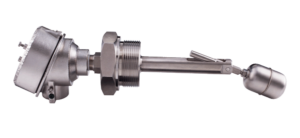

Float switch design was not always Deeter’s speciality, however. When the business was launched it was simply a distributor for them, until one day one of its customers approached them asking for a float switch. This is a type of contact liquid level sensor that uses a float to operate a switch. It was not something Deeter Electronics’ suppliers were interested in providing, and so Deeter Electronics set about designing and manufacturing the product themselves.

A Family Business

A Family Business

But while Deeter Electronics is a company that is already ready to change with the times, one thing that has remained consistently true is its commitment to its own people.

“Our staff are really important to us,” Whiteaker emphasises. “We are a family business, and as part of that, we put a lot of emphasis on taking care of our staff. It means our people tend to stay here a long time. Some have been here over 35 years.”

Whiteaker gives credit for that longevity to the crucial relationships built within the company.

“We look after our staff. They can come and talk to us about anything. We have found that if you treat the staff like family, it will be reciprocated,” Whiteaker points out. “It’s important to make work a comfortable and enjoyable place. We have a lot of very good members of staff with years of experience because they have been here for so long. That staff retention helps us to deal with our customers’ bespoke needs.”

That longevity is something that Whiteaker intends to build on moving forward.

“We are known as a reliable, long-term, family-owned company. We are growing and want to continue to do that while designing new products. We have just come off the back of a record year, and we are looking to continue that success,” Whiteaker says. “We are on the lookout for new opportunities to show what our products can provide. That’s the goal. We have a lot of confidence in our products, and we want the chance to show people that.”

Seeing how far afield Deeter Electronics’ products have already travelled, it will be exciting to see what they do next.