B&Q, Screwfix, Castorama, Brico Depot, Koctas & TradePoint, are household names in a very literal sense. If you are looking to conduct some home improvements, the odds are you have been to one of these stores. But behind those names is the Kingfisher Group, which operates across the UK, Ireland, France, Poland, Romania, Spain, Portugal, and Turkey, making it one of the biggest home improvement companies in the world.

Across that group, 45% of the company’s £13bn of sales in 2023/24 are made through the own exclusive brand portfolio, which includes multiple brands across different product categories.

“We have four main product categories,” says Neil Watson, Packaging Development and Operations Director for Kingfisher. “These are Kitchen, Bathroom and Storage, Surfaces & Décor, Outdoor and Technical.”

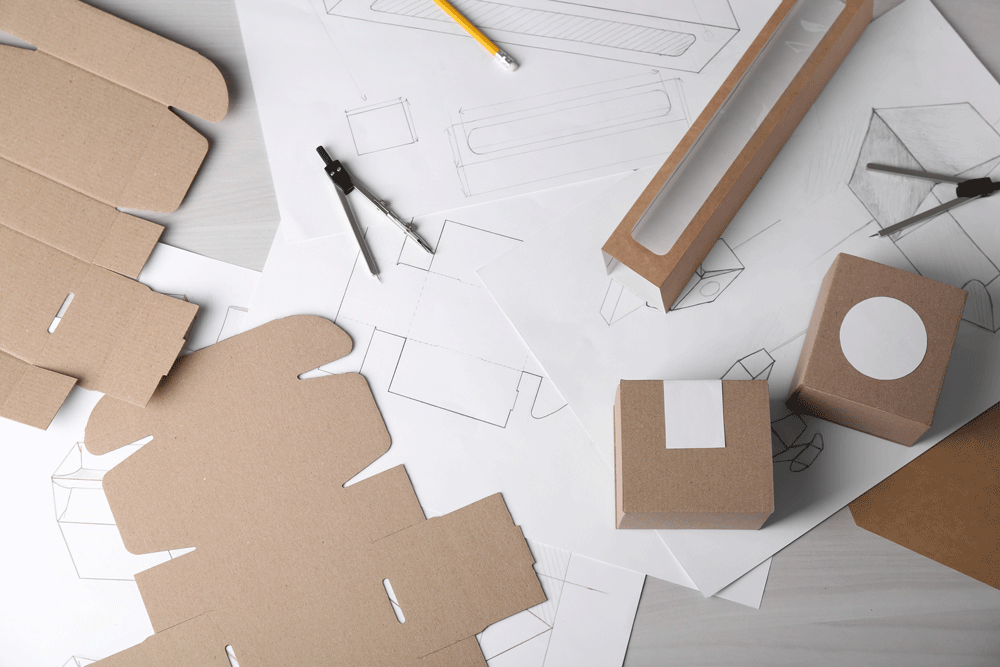

The Kingfisher Packaging and Localisation team supports the Kingfisher Group as a whole, through packaging design, development, and improvement across all the physical and structural packaging for those products. This is not just about ensuring the packaging is durable enough to withstand transit across multiple routes to market, it is also about making sure it is as sustainable as possible, in line with regulations across a spread of markets.

“The primary role of packaging remains protection, but it must also serve as a key player in brand communication and be included in the measurement of the total consumer experience. Packaging must work harder than ever, given the continual rise in e-commerce purchase decisions, legislative changes, and vast global supply chains. Legislation continues to drive progress—phasing out hard-to-recycle plastics and pushing towards a zero-waste mindset—but businesses are not waiting to be told what to do. We know that consumers are now reached across more channels than ever, and packaging must evolve and be measured accordingly” Watson shares.

First Line of Communication

In retail situations, packaging is often a brand’s first line of communication with the customer. Indeed, Watson is also responsible for the artwork on the packaging, ensuring it is applied in a standardised way, along with translation, to ensure the correct language and communication are used for each international market and regulatory requirements.

“We have a team of translation managers and validators in-house, working with our translation partner ‘RWS,’ taking data received in English and making sure it is localised accordingly,” Watson says. “In addition, we collaborate with ‘Impala’, a third-party agency whose responsibilities include producing the instruction manuals for the majority of our OEB products and making sure we have accurate, easy-to-read, easy-to-follow manuals.”

More Sustainable Packaging

More Sustainable Packaging

As well as ensuring Kingfisher is communicating clearly through its packaging, it must also ensure that packaging contributes to the sustainability ambition the company has set, driving continuous improvement year on year.

“We have a number of Key Performance Indicators in place, including a goal to reduce the amount of packaging we use year on year,” Watson says.

To benchmark for that goal, Kingfisher, measures the physical weight of its packaging at component level, comparing its figures year-on-year.

Circa 80% of Kingfishers OEB packaging by weight is cardboard with this having to be either FSC, PEFC certified or verified recycled with a full chain of custody to show a minimum of 50% recycled content.

“About 19% of our packaging by weight is plastic so we aim to have as much recycled content as possible,” Watson says. “We are reviewing that all the time looking for ways to increase the amount of recycled content without impacting packaging quality.

Progress is tracked and communicated every year in the Kingfisher Responsible Business Report. https://www.kingfisher.com/en/responsible-business.html

Less is more

Kingfisher does not just want more sustainable packaging, however. It wants less overall.

“Our ultimate aim is to make sure we have the minimum necessary physical packaging to protect the product,” Watson says. “As well as being a sustainability ambition, packaging reduction also has a significant impact on taxation. With ongoing legislative changes, businesses are being taxed increasingly on the packaging they use“says Watson.

As packaging is reduced, Kingfisher still needs to maintain the quality of its packaging and also ensure it can communicate effectively with the customers. That final goal can present a challenge as packaging gets smaller.

The Kingfisher Packaging & Localisation team also juggles with providing solutions that vary across its markets.

The Kingfisher Packaging & Localisation team also juggles with providing solutions that vary across its markets.

“Due to different merchandising and supply chain reasons, Screwfix’s packaging requirements may be different from B&Q’s” Watson points out. “Sometimes what’s needed is just a functional solution to protect and identify the product, but elsewhere the exact same product might be on display where it needs a higher level of customer interface and communication.”

Being able to achieve that with less packaging continues to be a growing priority as recycling infrastructure grows and governments seek tax revenue to pay for it.

“Governments need to improve recycling infrastructure to drive more circular economies, so they are adding more taxation to packaging,” Watson says. “We want to support that infrastructure development, but we also need to reduce our expenses in order to keep our prices competitive, ‘our strategy is primarily focused on reducing the physical packaging we have for the benefit of the consumer and the communities we operate within.”

It is a job that requires data, and collaboration.

“We have been working to develop an internal packaging application over the last few years that collects data, analyses and monitors all the packaging materials we buy from vendors across the globe,” Watson explains. “We have moved away from spreadsheets and email-based data collection to an application developed in partnership with ‘Merchant Agency’ to collect analyse and understand our packaging sustainability position. It recognises where we are not in line with targets and helps us identify where we need to focus our effort to drive continuous improvement.”

This application includes learning aids, videos, and tutorials not just for Kingfisher, but its vendors as well. In short, it is the full package.

Awards & Recognition

The Kingfisher team presented their sustainability ambitions and packaging application development at the Environmental Packaging Live Summit, held in London in June 2024, receiving great feedback for the work being done to capture and analyse packaging data and how Kingfisher is using this data to drive continuous improvement. This has led to the Packaging Application and supporting process being awarded a ‘Highly Commended’ at the UK Packaging Awards for the Corporate Social Responsibility Initiative of the year.