It is over 100 years since Italian entrepreneur Giovanni Schneider moved to Australia in the aftermath of the Great War and saw the opportunity to start a business. He began by sourcing really fine wool to sell to mills in the UK and Italy, and this trade between Europe and Australia formed the foundation of what would become the Schneider Group.

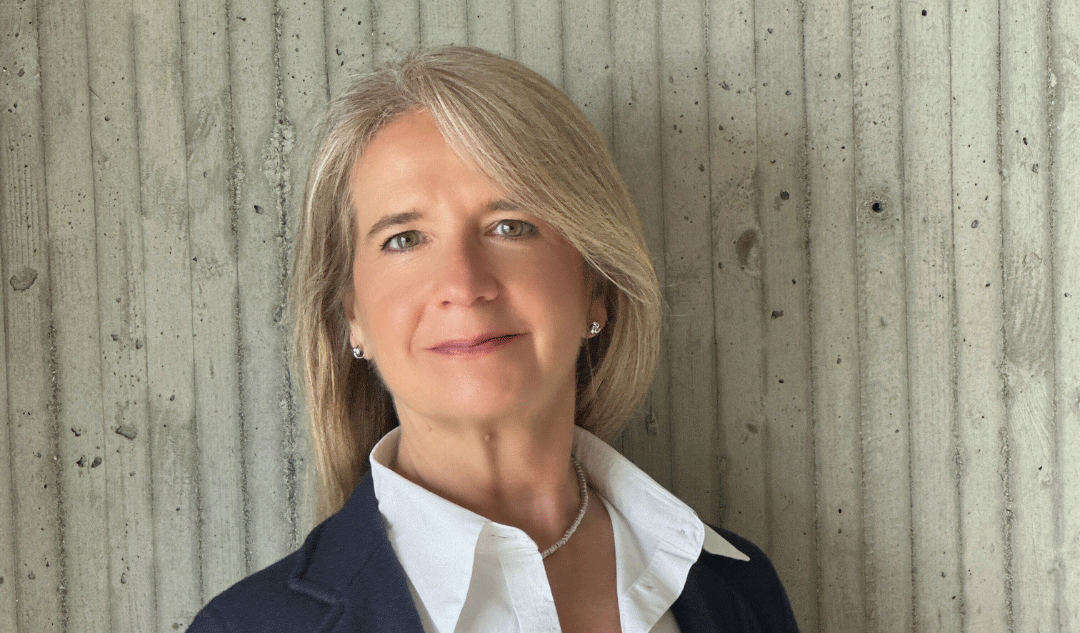

“Over a century has passed and things have come a long way since then,” says Laura Ros, CEO of Schneider Group.

Today Schneider Group is a trading and industrial company, buying wool from all over the world but primarily from Australia, New Zealand and South America. Schneider also processes that wool, combing it and turning it into sliver that is ready for spinning.

“This is done in three different mills located in Italy, Egypt, and Argentina,” Ros says. “We have important buying offices in Australia and New Zealand. We have also moved beyond wool to start working with other fibres. We have a mill in Mongolia that works with cashmere, and we manage a vast land in the Argentinian Andes where we shear wild vicuna, subsequently processed in Italy.”

Indeed, Schneider has expanded to cover the entire supply chain of sourcing, with about 20 farms in Patagonia providing wool for processing in Argentina.

“We are also partnering with local nomadic herders and herders’ cooperatives in Mongolia, buying the best cashmere and supplying it to Europe,” Ros tells us.

Quality and Sustainability

Quality and Sustainability

But while the scope of Schneider Group’s business has expanded, it has maintained its focus on quality.

“We have specialised in very fine wools, such as the ones consumed by the upper echelons of the European market,” Ros tells us. “We are talking about very precious fibres, so we need mills that can handle very fine fibres that are difficult to process. Our mill in Italy is able to process fibres that nobody else in the world can.”

Schneider Group pairs this quality in its products with its approach to sustainability.

“We have set up an integrity scheme program called Authentico®, which works with participating farms from the main merino wool-producing countries in the world,” Ros shares.

Farmers who take part in the integrity scheme answer a legally binding questionnaire about their practises, and those answers are verified and the farms audited through a third party for standards of animal welfare and social and environmental responsibility. Wool from those mills is processed in Schneider’s own certified mills, maintaining a meticulous chain of custody for the wool that, thanks to the certifications in place, is treated only using detergents that are totally biodegradable.

“Our plants are run with extreme attention to chemicals. Any water or energy we use is handled in a sustainable and environmentally friendly way,” Ros says. “We want our customers to know we not only guarantee sustainability at the farm level but at the industrial level, with robust digital traceability so they can be sure exactly what product they receive.”

Schneider Group has established itself as a firm that leads change, introducing new solutions at a global level that cover the whole supply chain from farmers to brands. It is a business model based on partnerships, positioning Schneider Group to leverage change across the entire industry.

The Modern Textile Sector

Schneider has continued to pursue these priorities even as the textile industry has been undergoing a challenging transition. The Chinese textile industry has grown to absorb a huge proportion of the market.

“If you want the less value-added production, move to China,” Ros says. “What is left in Europe and the West is a relatively small percentage of textile production, focused on the premium end of the market.”

Where 20 years ago Europe had tens of mills, today there are only three mills left on the entire continent.

“We have gone through many challenges as the textile industry has changed,” Ros points out. “The profit margin has moved to the end of the supply chain, depleting the margin for farmers. So this strategy of focusing on sustainability and quality has been a way of differentiating ourselves and surviving the various crises that we have seen. We have the most solid sustainability proposal in the market, and that has been a tough job. We are working with growers and NGOs to raise the bar. The last 20 years have been at times traumatic for the European textile industry, but we are still alive and kicking.”

While the industry is simultaneously shrinking and shifting upmarket, it means the necessary skills to keep that industry going are ever more in demand.

While the industry is simultaneously shrinking and shifting upmarket, it means the necessary skills to keep that industry going are ever more in demand.

“We hold that talent very dear,” Ros says. “Fortunately, the Schneider Group has always been a pleasant environment to work in. A lot of our workers, managers and managing directors have been with us for 25 to 35 years. We had one member of our team who retired last year after being with us for over 40 years.”

For the industry to continue, however, it still needs a regular influx of young talent. Propitiously, Schneider Group is investing in a solid pipeline of that talent.

“We constantly need to recruit motivated and interested young people into the industry,” Ros tells us. “We have a training and skill acquisition program. Human Resources are a key point for us because we know these skills are really hard to come by. We need to treasure them and grow them in-house. There is a very interesting Masters’ course in noble fibres created a number of years ago in Biella, Italy, a key centre for the wool industry. It is a post-graduate specialisation course that lasts a year and gives students an idea of the whole noble fibres supply chain, travelling around the world to see where wool and other precious animal fibres are grown, combed, spun, woven, knitted and turned into garments. Luckily we are seeing more and more young people coming out of university interested in this sector.”

One of the things that is driving this interest in the sector among young people is a growing awareness of where our clothes come from and the impact that has on the world around us.

“Unfortunately, over the years the growth of fast and ultra-fast fashion has meant textile use has moved towards synthetic, fossil fuel-derived fibres,” Ros points out. “In the mass clothing industry, synthetic fibres have partially killed the natural fibre sector, which is a shame for the health of people and the planet. Natural fibres, including animal and plant-derived fibres, are good for the body and health of people. It is important to make sure the consumer knows the pros and cons.”

While the industry is changing, Schneider Group is taking a long term view of its own development and the development of the industry as a whole.

“We have acquired our own special niche, but we have to consider the challenges ahead,” Ros says. “Sustainability is becoming more and more important. We have moved on from animal welfare to how you treat the soil, and ensuring you leave the land in better shape than when you found it so the next generation can enjoy it.”