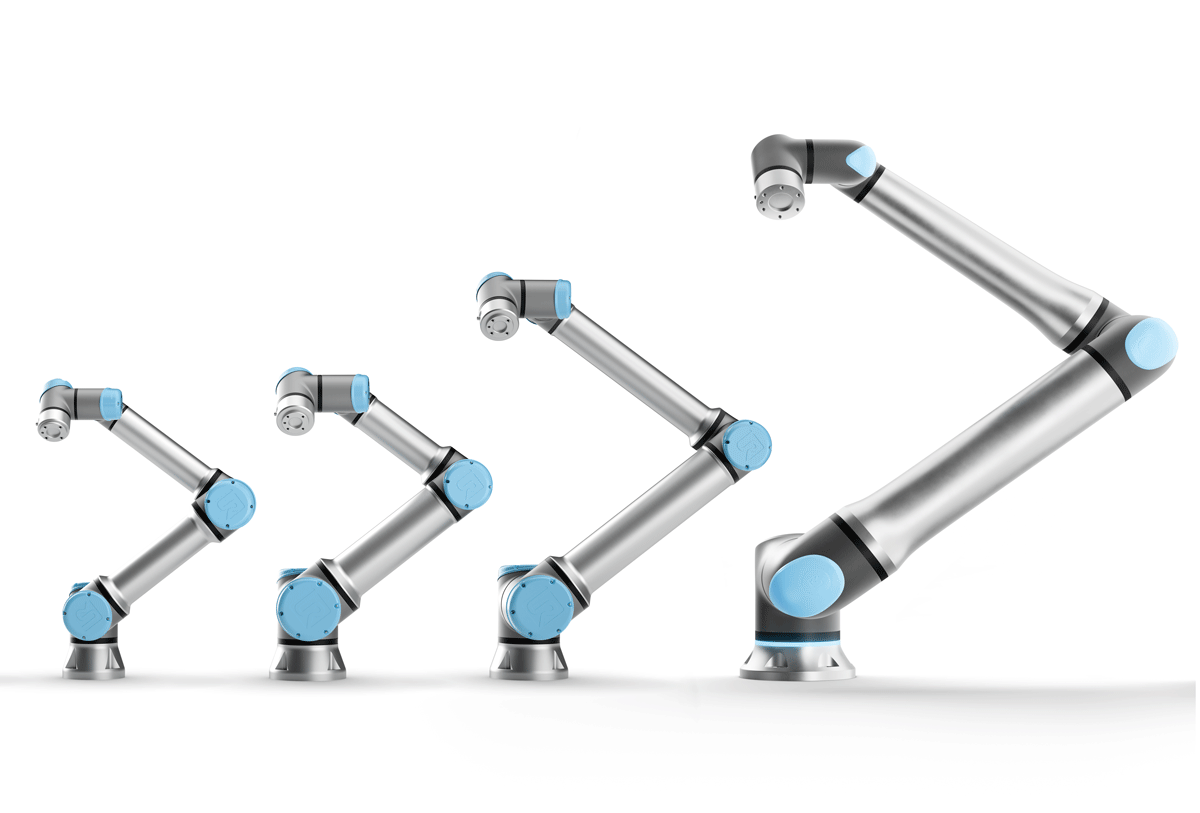

As demand for automation increases across all sectors, so does demand for robotic solutions. Universal Robots was established to meet that demand. Founded in Denmark in 2005 with the aim of providing lightweight robots that are affordable, easy to install and program to SMEs, the company has evolved into a significant global player, with over 75,000 cobots installed around the world.

“We are different from the traditional industrial robot manufacturers,” says Mark Gray, UK Sales Manager. “We don’t wait for customers to come to see our products. We take them on the road to show people their benefits. We also provide the software free of charge, without any licencing fees, which is also much appreciated, specifically by small businesses.”

He further explains that Universal Robots collaborates with other companies that make equipment to be fitted to the robots, such as different types of grippers and vision systems, to offer a comprehensive solution as required. “We have an ecosystem with more than 450 products that are plug and play compatible. Nobody else does that.”

In summary, cobots from Universal Robots give manufacturers access to all the benefits of advanced robotic automation, without the extra costs associated with traditional robots: complicated programming, long set-up times, and guarded work cells. This makes automation affordable even for small-batch production runs and mixed-product assembly. Today, the company has over 450 items in its UR+ portfolio to suit any business, big or small.

New products, new office

New products, new office

We interviewed Mark in 2022 and he admits that a lot has happened in the company since. “We have started to focus more on segments that we are particularly good at, such as palletising, welding and machine tending, and we have released robots with increased payloads specifically suitable for those applications.”

Over the last year, the company has launched the next generation of industrial cobots: the UR20, a new 20kg payload cobot that allows for even faster cycle times as well as the ability to handle heavier loads, and, most recently, the UR30 that builds on the same architecture as the UR20 and offers extraordinary lift in a compact footprint with superior motion control ensuring the perfect placement of large payloads.

“Another important milestone was the opening of the UK office in June 2023, the 30th office to open for Universal Robots globally,” says Mark Gray. “The office is based in Sheffield, right in the middle of the three manufacturing clusters of the north-east, the north-west and the Midlands and in addition to housing the corporate office for the UK, also encompasses the training centre and our demo suite.”

“We are really proud that Sheffield was selected as our UK base, with its famous industrial background. We are closely linked to the universities and the AMRC here as well,” he says, adding that Universal Robots is the only robot company in Yorkshire, which makes the location in Sheffield even more special.

Automate what you hate

When reflecting on market developments, he points out that UK customer perception of robots and automation is slowly changing. “Our road shows have a clear impact. We invite companies of different sizes and from different manufacturing sectors to come and see how our robots can improve productivity, trying to break down the perceptions that automation just isn’t for them. And we have been really successful.”

“Ultimately, we let them meet the people who will put all the equipment together into one package – the machine manufacturers, the gripper and ancillary device markers, and finally, the integrators. So, any potential question about the application and operation can be answered.”

Gray also points out that over the last few years, UK manufacturing has been catching up with the rest of Europe in terms of investment in automation. “We see that collaborative automation has been adopted a lot more quickly than traditional industrial robots, a development reinforced by the shortage of labour and the need for a short domestic supply chain. There are something like 76,000 open posts in UK manufacturing at the moment, and skilled employees are retiring. So, we’ve seen that age demographics lead companies towards looking at using collaborative robots to fill posts.”

“However, this does not mean that our cobots are going to replace the human workforce. One of the things that we are really passionate about is that people are the biggest asset of any business. By putting robots into a process, you want to achieve three benefits – better productivity, better quality and most importantly, better welfare for your employees. The cobots are to help with tedious, repetitive tasks that can be automated. The people can then use their skills and time on jobs adding more value, alongside the strapline ‘automate what you hate’. That really is the purpose of our cobots.”

Energised for the future.

Energised for the future.

Automation and robotisation clearly promote sustainability as well, helping to create a more sustainable supply chain. “If we automate at the same rate that China does, we can make products cheaper and more environmentally friendly, since we would eliminate the six-week delivery time around the globe on a container ship. Saving on logistics does not only save costs but has a major environmental effect as well,” says Gray, praising the company’s own supply chain, which enables its cobots to be delivered within just two weeks.

Speaking about the future, he affirms that the company is constantly evolving. Just recently, a major investment has been made in the Danish headquarters, where together with its sister company MiR, Universal Robots is breaking ground for a new, state-of-the-art facility in Odense. It will be the world’s largest cobot and autonomous mobile robot (AMR) hub and is expected to be completed in 2024.

“Universal Robots has a culture of positivity and creative energy. Because we are a disrupter, we do things differently, and this out-of-the-box approach makes it a really interesting, vibrant place to work,” he says. “We are continuously growing, continuously investing and moving in new markets. We are also continuously developing new products. So, customers can look forward to our innovations coming out over the next few years.”