Over the past 30 years, Solex Thermal Science has established itself as a globally recognised leader and developer of moving bed heat exchange technology that is used to heat, cool, and dry free-flowing granular materials such as solid granules, pellets, beans, seeds, and particles.

Born out of the Western Canadian fertilizer industry, the global company has since transitioned into industries ranging from oilseeds and sugar to sands and metals to name a few, with more than 1,200 installations in 50-plus countries and counting.

Solex CEO Gerald Marinitsch notes that while much has changed for his company over the past three decades, what has remained constant is a strong desire to help industries solve their toughest challenges.

“A customer-centric approach has been the basis of the business from the very beginning,” he says. “Because of that, we don’t supply standardised products. Our work with the customer starts with consultations to find out exactly what they need, trying to find the best solution for each specific application and specific circumstances. In other words, we are not providing equipment. We are providing solutions.”

Marinitsch points out that many of those solutions trace back to customers needing help producing a better product at less expense to them and the environment around them. As such, Solex has continued to evolve its product suite beyond the company’s proprietary MBHEs with solutions such as vertical plate conditioners with low-grade energy recovery that are helping the oilseeds industry reduce primary energy and steam consumption; and vertical tube heat exchangers that allow for the metallurgical industry to capture and re-use energy from difficult, high-temperature applications.

“Consequently, our solutions help improve internal processes, which indirectly lead to reduced primary energy consumption and the overall benefit of reducing GHG emissions,” says Marinitsch.

Expanded scope

Expanded scope

More recently, Solex has expanded into the energy-transition sector with collaborations on decarbonisation applications such as industrial energy (waste heat) recovery, concentrated solar power, and carbon capture.

This past summer, Solex announced it had acquired UK-based Econotherm, a recognised leader in the design and manufacturing of heat pipes and heat exchangers for industrial waste heat recovery. The company focuses on difficult-to-recover heat that includes hot and/or dirty exhausts in industries such as the automotive, metals, construction, food, mining, oil and gas, power generation, and pharmaceutical sectors.

Marinitsch says the acquisition represents a significant milestone for Solex as it further expands the company’s capacity to help its customers reduce the primary energy consumed to produce industrial goods.

“In our journey to support customers, decarbonisation is a recurring theme,” he says. “Customers need proven solutions to reduce their primary energy consumption and GHG emissions. Econotherm’s heat pipe heat exchangers are just that – real-world tested and robust enough to recover waste heat from exhaust streams that many industries had given up on. We are feeling well in a lot of areas where others stop. This is what makes us as a company strong and interesting, and is just another example of how we are meeting customers at their biggest pain points.”

Solex is also looking to increase its involvement in the iron and steel industry, a sector considered as one of the hardest industries to decarbonise.

“We are talking about large plants where a lot of energy is still wasted, and where our solutions can make a real difference in terms of energy recovery,” says Marinitsch.

Solex is also investing in a new wave of high-efficiency carbon capture solutions that are based on looping solid sorbents to adsorb and desorb CO2. Applying indirect heat exchange technology for the sorbents can achieve higher levels of efficiency that were previously unavailable with conventional solutions, says Marinitsch.

Global presence

Global presence

Moving forward, Marinitsch believes his 100-person organisation is well-positioned to meet the needs of customers all over the world. The company is based in Calgary, Alberta, Canada, with sales and service representatives located across North and South America, EMEA, and Asia-Pacific.

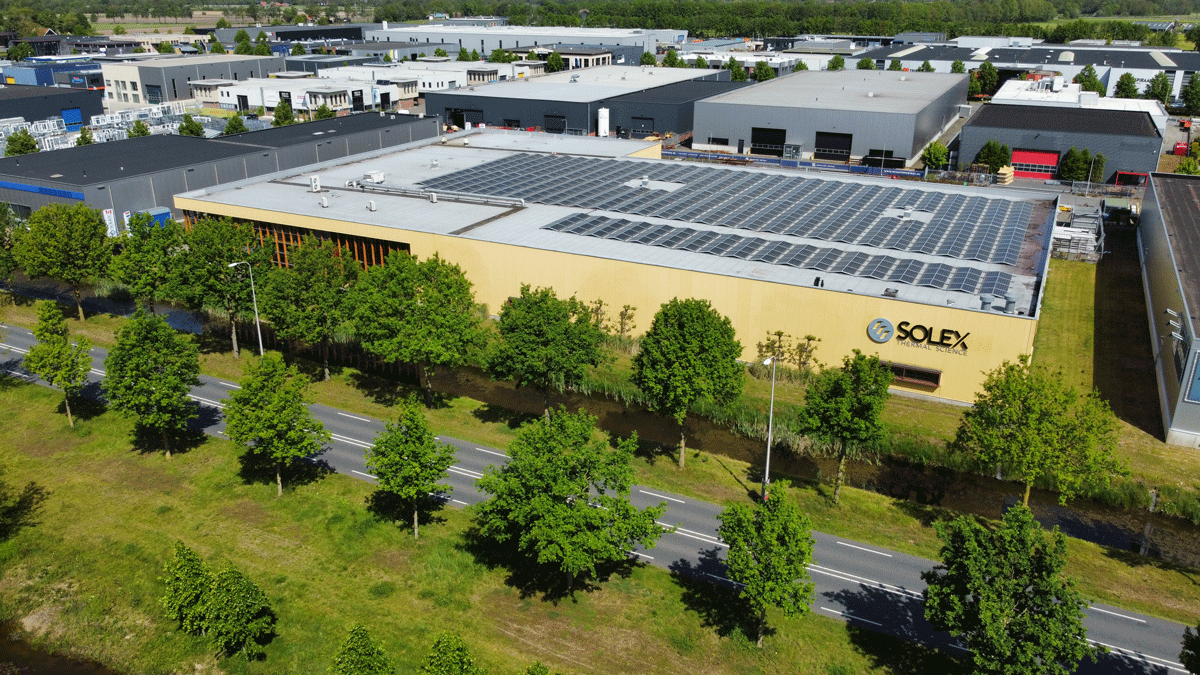

This is backed by the company’s robust in-house production capabilities. Solex operates a 4,000-square-metre facility in Haaksbergen, The Netherlands, that is highlighted by an in-house designed-and-fabricated pillow-plate laser welding and inflation process.

The state-of-the-art shop’s quality management processes are backed by ISO 9001:2015 and ISO 3834-2:2005, as well as pressure certified by Energie Consult Holland and the American Society of Mechanical Engineers.

Econotherm’s fabrication facility in Bridgend, Wales, meanwhile, is ISO 9001:2008 accredited – unique within the heat pipe manufacturing space. This has led to the company being at the forefront of heat pipe research and development, and a recognised leading manufacturer in many EU-funded projects.

“Having both a local presence and those in-house European fabrication capabilities gives us the ability to respond quickly to our customers’ needs all over the world, and again demonstrates our customer-focused approach,” says Marinitsch.

“Being a relatively small company that operates in a niche market and is spread over the globe is a certain challenge, but one that we have been handling very well. Our people represent the essence of Solex, and the reason behind our collective success over the years. Although we are spread out all around the world, we are a team that works together very well toward a joint objective.

“We are collectively determined to make sure Solex continues its growth path, continues its legacy of being an innovator and continues to supply solutions that meet customers’ evolving needs.”