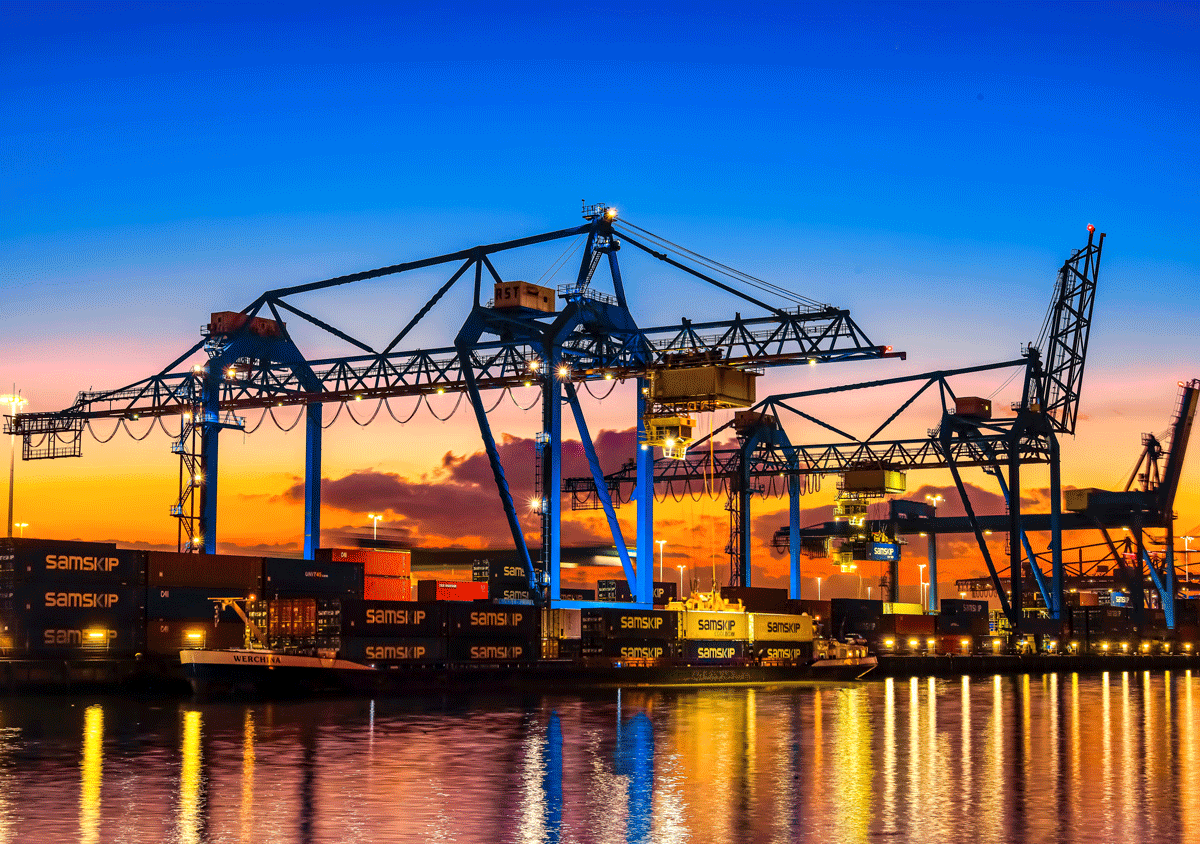

Rotterdam Shortsea Terminals (RST) is Europe’s largest shortsea shipping hub, offering container handling, storage and a comprehensive range of additional services such as empty depot, cross-docking and more, always with a strong focus on efficiency and sustainability.

Established in 1997, RST grew until April 2021, when it was acquired by Blue Ocean Capital and Crestline Investors. The new owners have further fuelled the development of the terminal.

Strategically located at the heart of the Port of Rotterdam, RST is at the centre of a comprehensive network with shortsea connections to and from Iceland, the Baltic states, Scandinavia, the United Kingdom, Ireland, Spain, Portugal and North Africa. Boasting 2,850 metres of quayside suitable for ships with draughts up to 13.65 metres, RST on average handles over 50 shortsea vessels per week and has secured smooth operations with a wide range of advanced equipment. Its terminal is trimodally accessible by truck, barge and train, allowing cargo to be transported quickly and efficiently.

Shore power green initiative

Shore power green initiative

Arno Storm, CEO of Rotterdam Short Sea Terminals, says that a lot has been achieved under the new owner over this last year and a half, not just in terms of performance but also of sustainability. “We set up a sustainability reporting and strategy in 2021 which was put into action in 2022 and involved several projects. Now we are starting to see the results of those initiatives.”

An important milestone was achieved in July 2023, when Rotterdam Shortsea Terminals joined forces with international logistics company Samskip to launch the first shore power green initiative. The aim is to dramatically reduce CO2 emissions produced by vessels docked by providing new clean shore powered energy solutions, the first of its kind for a container terminal in a Netherlands port.

Onshore power supply systems are a critical step towards the decarbonization of the shipping sector. Given that docked vessels currently leave their engines running to generate onboard electricity while burning gasoil constantly, the impact of green onshore power becomes abundantly clear.

Arno Storm says: “RST is committed to being a frontrunner in the energy transition and is taking a leading role in the Port of Rotterdam to work on practical solutions to serve the planet and RST’s customers. I am truly proud to be able to say that we are the first container terminal in the Netherlands which has a shore power connection.”

“The industry has made a relatively slow start with environmental initiatives but now it’s really starting to gain traction. Several shipping lines are now looking into their ‘greenification’ to fulfil their obligations to reduce emissions and to help to mitigate climate change. Partnering with customers and suppliers is key to progress towards CO2 neutrality, and I am thrilled that we have been able to take a first step, and pioneer new standards for other terminals in Europe.”

For the planet and its people

For the planet and its people

He further explains that Rotterdam Shortsea Terminals has defined clear objectives within its ESG policy. The company has established an internal Lean Academy to promote staff training, development and engagement, which is much appreciated by the employees.

“We have mixed classes of any position and qualification, so there can be a crane operator, finance analyst or a member of the management team, all interacting and sharing knowledge and experience, which increases the awareness of any challenge and brings up new, fresh ideas and approaches as well as enhancing skills.”

RST has approximately 330 employees and the human factor is a key element of business development, says Arno Strong. “We take good care of our people and try to provide good opportunities for their work and further growth. We believe that if people are happy and the working environment good, then everybody does their utmost best to deliver the service to our customers, and the business flourishes.”

As a relatively small terminal within the Rotterdam area, RST is committed to working in partnerships to test new approaches and pilot projects, such as the use of hydrogen for the equipment. “We are looking at establishing a hydrogen filling station at our terminal as we get around 1,000 trucks a day, as well as inland vessels which are now also looking into hydrogen solutions.”

Internally, the company has switched to green energy for the electrically driven cranes and has purchased a share of a solar power farm to cover 15% of its power needs. Further 600 solar panels are now being installed on two of its buildings, which will make them carbon neutral. Also, 25 EV charging stations have been installed with another 50 to follow. “The objective is to be carbon-neutral by 2030 within scope 1 and 2 and then to focus on scope 3.”

Enhanced operation

As part of the supply chain, RST has been very proactive in finding solutions to mitigate the disruptions of the last few years, investing not only in new projects but also internally, in connection with the private as well as public sector.

“We’re very much connected to the government authorities, to the Port of Rotterdam, and strive to be part of the bigger ecosystem, of the bigger developments. Partnerships are key – the more brains in the game, the better the solutions found.”

RST is set to invest €8 million into new heavy transport machines which will be hybrid, with the biggest investment being into new cranes within the next two to three years, totalling some €60 million in advanced equipment to make Rotterdam Shortsea Terminals future-proof.

“One aspect of our work that is of paramount importance is safety – the safety of our people, safe operation of our equipment. We have taken huge steps in this respect; we worked on the safety system and safety leadership with our middle as well as senior management.”

“Another one is customer focus, and this has further enhanced over this last 18 months. Our overall productivity and speed of container handling has increased by 15%. We have significantly improved the reliability of services with neighbouring rail terminal and have increased automation of the gate, reducing turnaround times at the terminal from an hour and a half to less than 45 minutes.”

“Our approach is that of continuous improvement and full transparency, progressing and innovating together with our partners,” says Arno Storm, affirming that RST is proud of its achievements under the new owner, which will benefit both customers and the planet.