Olon SpA is a developer and manufacturer of APIs with a global production footprint that includes eleven production sites in Italy, eight in Spain, one in the United States, and one in India, allowing it to serve most of the market around the world.

Owned by Italian chemical firm, P&R Group, Olon SpA has grown over 40 years through a combination of acquisition and organic growth, last year achieving a turnover of $600 million across the Generics and CDMO sectors.

“Our business is more or less 60% Generics and 40% CDMO,” explains Giorgio Bertolini, Vice President for Research & Development at Olon SpA. “We are investing a lot in building our presence in the CDMO arena to eventually achieve parity with our Generics sector. But the Generics industry is also growing very fast, so we need to speed up the growth of CDMO!”

In addition to that, Olon SpA also has two production sites fully dedicated to biotech, particularly biomanufacturing, through microbial fermentation. But regardless of the specific technology that Olon SpA is working with, the company’s major differentiator is its ability to act as a one-stop-shop across a multidimensional system.

“We can really follow the process and development of a product,” Bertolini explains. “We can follow the development of new projects and new products from the beginning, for example at the preclinical and early clinical phase studies, particularly in our production site in the US. Then we can move into Europe to focus on late clinical phases in the development of new APIs and be ready for large-scale production and commercial distribution.”

Technology Through Growth

Technology Through Growth

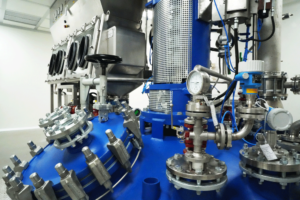

At the same time, Olon SpA has a broad technological portfolio, including biotech. This means that Olon can support its customers across all the technical steps for the production of APIs, from raw materials to producing intermediates across its industrial footprint and finally delivering the finished API through a range of different technologies.

“We can really follow the pro-cess starting from raw materials to the final API,” Bertolini tells us. “We have all the technologies on our sites to support every technical step needed in the processes.”

The selection of technologies only grows wider as Olon pursues an acquisition-based growth strategy.

“We acquire many new technologies through company acquisitions,” Bertolini points out. “Sometimes we acquire production sites with the goal of acquiring a specific technology. Step-by-step we are increasing our technological portfolio to support the chemistry required for the production of the API.”

A Greener API

Olon also collaborates with universities to maintain its position at the cutting edge of technology, future-proofing the firm & creating a biotechnological hub in Italy.

“We have three university groups and one small company here in Italy to develop new biotech processes for the production of APIs,” Bertolini tells us. “Specifically, we are trying to achieve a more sustainable and greener approach than standard chemistry. We are trying to be greener and reduce our carbon footprint for the future.”

Bertolini is adamant that sustainability will play a key role in supporting the future growth of Olon SpA, most of the firm’s research and development efforts are focused on creating greener chemistry.

“Regarding sustainability, we are not working only on new greener processes, but also investing a lot in our production sites, installing solar panels for the production of electricity, working to generate a huge capacity,” Bertolini says.

A New Facility

Most recently the attitude of investing in Olon SpA can be seen through a new $23 million facility, which will house an ultra-high-containment production line to produce high-potency and toxic products.

“When it was established in the 1970s Rodano was one of the first production sites in the world to manufacture a cytotoxic drug that requires high containment. We have a long tradition and decades of experience in how to handle these materials,” says Bertolini.

But while the plant is well-established, Olon has plans to bring that operation to two new levels, larger scale, and higher containment.

“We have just completed an investment for a new plant to produce a higher quantity of High Potent API than ever before,” Bertolini insists. “We are transitioning from a production quantity measured in grams to one measured in hundreds of kilograms of high potent material used for procedural medicine.”

The last decade has seen a great deal of research and development into these new drugs, which are selected for specific enzymes that can treat sub-types of diseases such as breast cancer.

“Where there was one type of therapy, now there are specific therapies for specific subtypes of breast cancer. These high-potency APIs require high containment because we cannot expose our people to them, so we prevent cross-contamination during production,” Bertolini points out. “Normally with high-potency APIs, you are talking about very small daily doses of drug, but there are some diseases that unfortunately have a lot of patients. So even though you need small doses, you need a large quantity of active pharmaceutical ingredients (API).”

“Where there was one type of therapy, now there are specific therapies for specific subtypes of breast cancer. These high-potency APIs require high containment because we cannot expose our people to them, so we prevent cross-contamination during production,” Bertolini points out. “Normally with high-potency APIs, you are talking about very small daily doses of drug, but there are some diseases that unfortunately have a lot of patients. So even though you need small doses, you need a large quantity of active pharmaceutical ingredients (API).”

At the same time, Olon is looking to go further in increasing its containment measures for the production of very high-potency products.

“We can reach an exposure level lower than nanograms per cubic meter,” Bertolini tells us. “It is essential for the production of these toxins.”

That containment level is a differentiator for Olon.

When the company was founded in the 70s it was to handle these products. “You don’t just need a new plant, you need knowledge and know-how,” Bertolini insists. “We can provide this full service. We are reliable because we have knowledge in this area going back 50 years.”

Bringing Innovation Together

At the same time, Olon is making a further big investment, this time in a new Research and Development Hub. The Hub is due to be completed this September and has been designed as a focal point for Olon’s unique R&D system. While the firm has a development team of 300 people, until now they have not had a central research and development facility. Instead, smaller teams have been widely distributed across Olon’s sites, keeping them close to the production and distribution of the solutions they create.

“People are working close to the plant and the operators, so they can develop the right mindset to design, develop and optimise real industrial processes,” Bertolini says. “It means our researchers know what an industrial plant can do, not just how it behaves in the lab. In addition to that, they can specialise in specific technologies that are key differentiators for each site.”

But while that localised strategy has advantages, it also eliminates cross fertilisation and means knowledge is not distributed effectively across the company.

“We built this new hub so that knowledge and information will be shared, consolidated and redistributed across all of our R&D teams,” Bertolini says.