Ashlyne Fabrications has been successfully serving customers for over 30 years. Driven by a commitment to provide complete customer satisfaction while maintaining unrivalled relationships with a number of large, international companies, Ashlyne brings to bear a team of highly-skilled craftsmen and engineers with the knowledge, experience and expertise necessary to carry out an enormous variety of specialist fabrication assignments to suit all industries and requirements.

“Our key strengths are quality and an ability to meet stringent deadlines,” says Ian Mitchell, Ashlyne Fabrications’ General Manager. “We have got a small, highly skilled workforce, our production is planned correctly, and we are looking to implement ISO 9000 to ensure that level of quality still further.”

Until recently, Mitchell was the owner of Ashlyne Fabrications, however in 2021 the company was bought out by the entrepreneur Daniel Beaumont, to join his Group alongside names such as Paragon Toolmaking, Fairgrieve Compression Moulding and Aurora Profiles.

By staying on as General Manager of the company, Mitchell ensures that the firm will continue to benefit from his experience and ensures continuity in its relationships.

“I’ve talked to customers and suppliers and assured them things will continue on a level playing field,” Mitchell says.

Ashlyne Fabrications facility is strategically positioned near the motorway network, based in Dukinfield, Cheshire. Here Ashlyne maintains a 6,000-square-foot factory unit which benefits from two ten-tonne overhead cranes.

Ashlyne Fabrications facility is strategically positioned near the motorway network, based in Dukinfield, Cheshire. Here Ashlyne maintains a 6,000-square-foot factory unit which benefits from two ten-tonne overhead cranes.

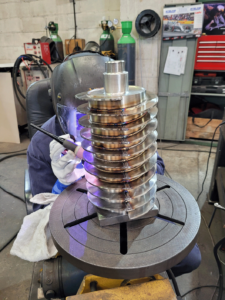

This facility is equipped to offer full steel fabrication, welding and engineering services, operated by a small but dedicated and highly skilled workforce.

Weathering Challenging Times

Although Ashlyne has been operating for more than three decades, and in that time it has seen numerous economic and political events unfold, but Mitchell is the first to point out that the company is seeing some unprecedented times right now.

“I think our biggest achievement has been succeeding through this recession,” Mitchell says to us. “We have been through a number of recessions, but with Covid, the War in Ukraine and the cost of living crisis, all one after another. If we can get through that we can get through anything.”

Unsurprisingly, an essential element of Ashlyne’s ability to navigate these turbulent times is its ability to carefully manage its own supply chain, and make savings it can pass on to the customers.

“The biggest challenge is securing materials at the right price so that we can set the right price for our quotes and secure the right work,” Mitchell says. “If we can buy in at the right price, we can quote at the right price. Getting raw materials and goods and services at the right price is our priority.”

Mitchell succeeds at this through the longstanding relationships he has maintained across Ashlyne’s supply chain, but he explains this is as much about the breadth of relationships as the depth of them.

“We have numerous suppliers and always have a good ring round to check the current situation with different providers,” Mitchell says. “We don’t rely on any one-stop-shop. We will have several different suppliers for the same product. I don’t always go with the cheapest because that is not always the best option. But all my suppliers have been checked and approved over the years, so I know exactly what I’m getting.”

A Skilled Team

A Skilled Team

The materials that Ashlyne sources are useless at any price, however, without the skilled work of Ashlyne’s team of engineers and craftspeople. Managing that team well is how Ashlyne succeeds at what it does.

“I try and keep the lads happy,” says Mitchell. “I pay the going rate for the job. Most of my lads have been here for a while. Some of them have been here for 20 years, some of them for ten years. We only have one relatively new member of staff who has not been here very long. Having such a longstanding staff means that I know their strengths and weaknesses. That means that I can put them on the work that I think is suitable for them and that they like doing.”

Mitchell is working to find those people yet more of that work, and he is focusing on upgrading the company, its facilities and capabilities so that it is able to take on still more ambitious work.

“Going forward this year, we are deploying the ISO system and getting our welders certified to standards that will open doors for us,” Mitchell tells us. “All of our customers are longstanding customers. Some of them have been coming to us for 20-odd years, but you don’t want to stand still. You want to open new doors.”

Ashlyne serves a wide variety of customers, some of whom are project engineers that will move from place to place and project to project, but who know Ashlyne’s ability to provide quality and meet deadlines and are happy with its quotations.

“Some of these customers will have quality systems in place that we need to meet, but they have told us that once we do that we will be on their suppliers’ list,” Mitchell says. “We have now recruited a woman who has worked with these quality systems, so when we start going down that path we will be better equipped to meet those criteria.”

The next step, Mitchell points out, is to expand Ashlyne’s 6,000-square-foot factory unit.

“Currently we are in a single-story industrial unit but we only occupy half of it,” Mitchell tells us. “When the other half becomes available, we want to take that on and expand the workforce. We have promises of work coming in and want to expand our capabilities and capacity to meet that. We have been keeping ourselves on a level playing field over the last couple of years, and now that has put us in a strong position to grow from.”