With Kayser employing 3,600 people in its 11 locations in Asia, America and Europe, the Germany-headquartered company leverages its extensive know-how and experience to offer solutions designed to meet customers’ specific requirements.

Dr Sebastian Bunzendahl, Senior Vice President Purchasing, affirms that the company is well-positioned to embrace the challenges arising from sector transformation, driven by the shift from combustion engines to electric mobility.

“The transition presents both opportunities and challenges,” he says, pointing out that although Germany’s target to ban combustion engines by 2030 is now considered unrealistic by many, the industry must still innovate rapidly in line with the evolving landscape.

“The drive towards e-mobility is not consistent globally. While Europe and China are investing heavily in electric vehicles, the US market presents a unique challenge due to its vast distances, which make petrol-powered cars more practical. Meanwhile, emerging markets such as India and Brazil continue to rely on traditional fuel technologies, necessitating a balanced approach from automotive suppliers.”

Future-Focused and Adaptable

He further notes that one of the reasons why Kayser has grown over the years is its future-focused approach and adaptability; these attributes continue to make the company resilient. “We have a very good split between the old and new technologies, catering to various market demands, providing assemblies and systems for both combustion engines and hybrid vehicles, plug-in hybrid electric vehicles (PHEVs), and battery electric vehicles (BEVs).”

“What also makes us successful are our close relationships with Original Equipment Manufacturers (OEMs). Together we are developing technologies for tomorrow,” he says, adding that internal integration of purchasing, sales and R&D is key for establishing a strong supply chain, a very important aspect of success.

“The early integration of purchasing and suppliers is crucial in developing cost-efficient and innovative solutions. By identifying cost drivers and immediately evaluating new concepts, we can ensure that solutions remain within budget.”

Sustainability has become a critical concern for automotive companies, particularly in the light of stringent European supply chain regulations. Kayser supports the ten principles of the Global Compact and integrates them into its day-to-day activities. The company also follows a “local for local” production strategy as much as possible, minimizing supply-chain disruptions and reducing its carbon footprint.

“Suppliers are part of our success, and we apply strict criteria for supplier selection. Supplier onboarding now involves not only financial and quality assessments but also compliance with sustainability and ethical standards,” says Dr Bunzendahl.

He affirms that Kayser has embraced AI to enhance supplier selection, risk assessment, and cost control. AI-powered analytics enable predictive insights, optimizing decision-making and reducing operational inefficiencies.

Artificial Intelligence as an Enabler

“Implementing a targeted AI strategy is not an optional upgrade – it is a strategic imperative. In the automotive industry of tomorrow, only those who act decisively today will remain competitive,” he affirms.

“At Kayser, artificial intelligence is far more than a tool – it is a core element of our value creation model. From supplier risk assessments and dynamic cost control to predictive supply chain resilience, AI-driven decision-making gives us speed, precision, and a clear competitive edge.”

“The real challenge is not whether to use AI, but how. Identifying the right application areas, building a scalable data strategy, and empowering teams with the right capabilities are key. This is where our ‘Purchasing 4.0’ strategy comes in: we are reimagining procurement as a data-driven, AI-powered control tower for sustainable value creation.”

Kayser has been at the forefront of the “Purchasing 4.0” revolution, a concept that integrates AI, big data, and digitisation into procurement processes. While Industry 4.0 is well-known for optimizing production through automation and data-driven insights, Purchasing 4.0 applies similar principles to sourcing and supplier management.

“Data enrichment is not just about aggregation – it’s about connecting the dots across systems, suppliers, and geographies to derive actionable insights. We enhance raw data with contextual information to support faster, smarter, and more forward-looking decisions across purchasing, supplier management and cost engineering.”

“A common concern regarding AI adoption is the potential displacement of jobs,” Dr Bunzendahl reflects. “However, I view AI as an enabler rather than a replacement for human roles. The future of procurement lies in equipping professionals with the skills to interpret and leverage AI-generated insights effectively.”

“Rather than eliminating jobs, AI will reshape roles, requiring employees to develop new competencies,” he continues. “Training and upskilling programmes will be essential in ensuring that personnel can harness AI tools effectively while maintaining human oversight. That is also the purpose of the EU’s AI Act – any company that is using AI must provide AI training for its employees.”

“One of the key aspects we are now looking at is leveraging dark data—unused or unstructured data hidden within organizations. By tapping into this data using AI, companies can unlock valuable insights that drive efficiency and cost savings,” says Dr Bunzendahl.

“At Kayser, we don’t see Big Data as a buzzword – we see it as a business-critical asset. Data is the new fuel of our supply chain. It enables full transparency, proactive risk management, and measurable progress against sustainability goals. Data enable us to map supply chains down to the smallest detail. Understanding where costs and emissions arise is the first step toward effective optimization. Data are also the key to making CO₂ goals measurable and actionable – a non-negotiable factor for any future-ready organization.”

“The convergence of Big Data, Dark Data and AI is a strategic lever. It allows us to transform purchasing into a predictive and value-generating function – with full traceability, agility and long-term resilience built in. That’s what defines Purchasing 4.0 at Kayser: not reactive cost control, but proactive value orchestration.”

The Future of AI and Digitisation in Automotive

He affirms that as Senior Vice President Purchasing, his goal is not just to apply AI – but to strategically shape it. “The companies that invest in the right AI architecture today will be the innovation leaders of the next decade. Kayser is ready to take that leadership role – with a clear mission: data-driven, responsible, and future-proof.”

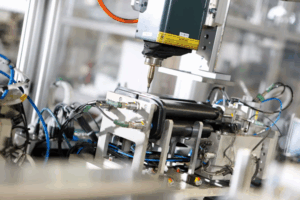

Given its future-oriented mindset, Kayser continues to expand, as shown by its latest investment in a new plant in Bulgaria. Under an initial 10-year agreement, the company last year leased facilities at the BPD Pleven logistics park, where it will manufacture components such as pipe systems, valves and tanks.

“We have been growing organically through all of our history, driven by our excellent R&D capability and our collaboration with OEMs to develop next-generation automotive solutions. That is set to continue,” says Dr Bunzendahl.

As AI, digitisation, and the Internet of Things (IoT) are set to redefine the automotive industry further, companies that successfully integrate these technologies into their operations will gain a competitive edge. Kayser Automotive seems to be one such company. By leveraging the advantages of artificial intelligence, Kayser is not only securing its future but also contributing to the broader evolution of the automotive sector.

In concluding, he points out that although artificial intelligence is a key enabler, every company needs to find the right approach tailored to its own structure, maturity and objectives. “If anyone is considering how to implement AI effectively in their procurement or supply chain organization, I’m happy to exchange ideas and share insights. From identifying potential use cases to evaluating readiness and scaling impact – this is a topic I am deeply passionate about,” he says.

“To support this, I’m also happy to leverage my AI network – including experts from industry, research and consulting – to help companies find the right solutions and partners for their individual transformation journey. Feel free to reach out to me via LinkedIn referencing this article – I’m always open for a strategic conversation.”