As every industry is pushing for sustainability and the transition to electric and renewable energy sources, batteries have become big business. But while this is an industry with plenty of new kids on the block, Leclanché has been making batteries for well over a century.

The company was established in 1909, based on the patents of the inventor George Leclanché who it was also named after. Leclanché’s key invention was the Leclanché cell, which defined modern electrical batteries and laid the way for the modern dry cell battery.

Over the years the company has stayed up to date with the latest technological developments in the field, producing a whole spectrum of products. In 2006 the company underwent its latest evolution when it decided to refocus on lithium-ion battery technology. It acquired Bullith AG, later renamed Leclanché Lithium GmbH, a company involved in the production of lithium-ion batteries. The company spun out of the Fraunhofer Institute for Silicon Technology, where it had made developments Leclanché was uniquely well positioned to industrialise.

“That started a long process of taking a lab technology and turning it into something you can manufacture,” recalls Pierre Blanc, CEO of Leclanché.

While there are a number of rapidly expanding mass markets in the battery sector, Leclanché’s focus is a bit more bespoke.

“We are not addressing mass, high-volume markets, but we service specialised markets where the performance characteristics of the cell would play an important role in the overall decision-making of customers and cost structure,” Blanc says. “We are focused on niche markets for heavy duty applications.”

A key decision when Leclanché defined its new strategy was that it focused not just on heavy duty applications, but applications in the decarbonisation and renewable energy integration space. It was a plan that went beyond simply manufacturing batteries for sustainable applications. Even Leclanché’s manufacturing processes have been redesigned to be more environmentally friendly.

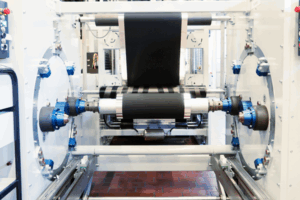

“That involved a number of steps,” Blanc says. “The main step was the removal of organic solvents from our manufacturing processes and replacing them with water. That had immediate consequences, including reducing energy consumption requirements for dry rooms. We moved to P5 materials and away from fluorinated materials, which are already under discussion to be banned.”

Leclanché was one of the first companies in the world to move entirely to water-based manufacturing, and even today it is the only company capable of manufacturing all of its components with P5 (which stands for Product, Process, People, Planet, and Prosperity) materials.

“We have been a battery company focused on specialised markets throughout our history,” Blanc tells us. “We took a big turn from alkaline and acid batteries to focus on lithium, but we are staying in specialised markets.”

When it comes to selling those markets, Leclanché can make a strong case for itself from both business and engineering perspectives. But Blanc prefers to let Leclanché’s customers do the talking.

“The feedback we get from clients is that we provide the most cost-effective solutions over the lifetime of their application,” Blanc says. “We tailor batteries’ performance and electrochemistry to ensure the clients get solutions optimised for their applications and operational costs, getting them the best possible return on their investment. We offer a combination of technology, processing and tailoring for key niche markets.”

From Theory to Practice

The latest era in Leclanché’s development started with its acquisition of Bullith AG, now Leclanché Lithium GmbH. However, taking a new idea, even a proven concept, and turning it into a marketable product, is a big challenge in and of itself.

“Technologies, battery technologies in particular, take a long time to be industrialised and validated,” Blanc explains. “Taking a potential technology from a lab and making a product out of it is time consuming, costly and comes with a lot of risks.”

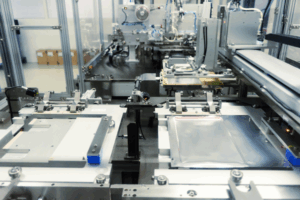

It is a step where a lot of companies run into difficulty. You have to take a concept and turn it into a product, you then have to make the product cost effective, and make its results repeatable.

“We need to produce not just one working battery cell, but millions of them, all identical,” Blanc tells us. “It is technology driven by process control, and good process control means experience with the process, which requires a steep learning curve.”

That learning curve takes place at the level of individual staff members. Finding those people with the necessary expertise to drive and use the technology is key.

“That is one of the more difficult aspects of the business. We are recruiting people to come into an area of transformation,” Blanc points out. “We are looking at new forms of energy transmission, new ways of decarbonising transport, while bringing on board people who can contribute to the business.”

To achieve this, Leclanché works with universities, exposing students to the industrial environment and giving them an entrance into the industry. The company’s recruits are not the only ones it needs to educate, however.

Educating the Client

Blanc explains that one of the big challenges in the industry is gaining sufficient experience to control processes efficiently at scale. That is in the context of a market with a lot of expectations, and one where promises can be over-optimistic.

“There are expectations in the market that a more traditional battery manufacturer might have set, which means convincing customers on why you are being less aggressive and take more time to complete certain steps,” says Blanc. “There are high expectations for things to happen, and happen quickly.”

It is not enough to develop the product, clients need to adapt it to their own needs, and it needs to receive the necessary external certifications not just for the battery but the application as a whole.

“It is a market that has very high entrance barriers which means it adds to the time to bring the product to market,” Blanc says. “Our approach is to maintain very close relationships with the customer.”

Part of that relationship has been about education.

“We have been in the market as it has evolved over the years. When we started in this market customers were not experts on batteries and electrification,” says Blanc. “They needed a lot of help and support in understanding the technologies, what is realistic and where the potential risks were. We continue to accompany the clients as partners, build their understanding and help them move through the process as they learn about the technology.”

Our conversation with Blanc keeps coming around to technology, and ultimately technology is what drives the business.

“We are a manufacturer, but we are primarily a technology company,” Blanc says. “We bring novel technical solutions to our customers to address their needs. The company will continue to do that as a technology leader in the industrial space. We are not aiming to be an R&D company, but to develop products for manufacturing, reducing carbon footprints and enabling sustainability.”

That vision has laid the path for Leclanché’s future.

“Our goal is not to be the biggest producer. We are a company that historically always focused on specialised applications,” Blanc says. “We want to continue to that, focusing on applications where clients can very clearly and easily determine the added value we bring.”