In 1985, a small business was founded in Denmark by Hans Kjellerup, as a Sales Agency for Ruston Gas Turbines (RGT) of Lincoln UK. Growth of Combined Heat & Power (CHP) plants across Scandinavia and increasing North Sea Oil & Gas production resulted in sales to the region surpassing 50 units (£150m) with corresponding growth of the agency.

By the turn of the century, RGT changed ownership with ALSTOM taking the reins. ALSTOM’s approach to growth was based on local independent partnerships. The agency quickly evolved into a dedicated Service Centre covering the Ruston range and supporting spares sales and servicing requirements throughout Denmark, Scandinavian and Baltic regions. This ability to quickly evolve and flourish defined the path the business has taken on its journey to where Gas Turbine Services is today.

In 2003, the Ruston name passed to SIEMENS and with it, the rebranding of the Ruston products into the 5mw to 15mw range of SIEMENS Gas Turbines.

The next five years saw consistent annual growth and, in 2008, a change in direction as the new owners, Roy Kjellerup (CEO) and Rob Dye (Technical Director/Co-CEO) started the process of creating Gas Turbine Services.

In the same period, the dynamics in the energy sector were changing, with environmental pressure towards renewables and wind power along with depleting North Sea O&G reserves, eliciting the need for change. With territorial restrictions tied to OEM representation, it became obvious that to maintain and grow market share, the partnership between Gas Turbine Services and the OEM needed to reach its natural conclusion.

Independence became a reality in 2015, with Gas Turbine Services separating from its OEM partner whilst at the same time, investing £5 million in a new facility, quadrupling engine build capacity and marking the beginning of an exciting new period as it looked towards global growth.

“From 2015 onwards, the world changed,” recalls Rob Dye. “The crude oil price collapsed, Wind Power was increasing, and CHP was no longer seen as a green solution. With the global energy market in flux and our domestic market reducing, we looked inwardly and invested heavily into both our workshop facilities and, as importantly, critical spare parts stock holding.

With the advantage of spare capacity of both critical parts and multiple spare core engines, we used our time and money wisely, investing into our own fleet of core engines in readiness for when the market recovered which it inevitably did”.

From there Gas Turbine Services began a sustained period of growth as it secured business globally. In 2020 the firm decided to make a further £10 million investment into a new ‘state of the art’ testing facility and in addition, in 2024, a further £4 million expansion programme into their UK facilities.

“Over the last ten years, our domestic market reduced from 95% of annual turnover to less than 5%. At the same time, global turnover and profit margins increased, and we have secured contracts on all major continents,” says Rob. “The UK is one such market where there is an opportunity to increase our market share.”

“The East Midlands is at the very heart of gas turbine technology and design,” Rob tells us. “We’ve had a presence in Lincoln for the last 15 years, predominantly technical support to our core business in Denmark. We are now increasing that presence, specifically in workshop capacity and capability as our business continues to develop.”

“We are an Anglo-Danish company that takes the best of both cultures, so the UK is the natural place to increase our capacity as the business grows,” says Rob. “The majority of our suppliers are here along with the OEM, therefore, where better place to recruit and expand.”

Embracing Opportunity

Gas Turbine Services is on a growth trajectory and has always operated in a finite market.

“We work in a bespoke business,” points out Rob. “We specialise in the products we work on and have a percentage share of that market.”

In addition to the OEM, there are two further providers, Gas Turbine Services being the only ‘fully independent’ one.

There was another independent provider, however recently this company collapsed leaving their customer base in chaos. Prompt actions by Gas Turbine Services resulted in them securing 80% of these customers and quickly bringing stability back to the market.

With the Company’s forward-thinking policy, engine build capacity and high stockholding reserves, Gas Turbine Services has seen its biggest leap in growth yet.

The SGT turbine business is relatively small and interactive “We look after our people, and the word soon spreads so it’s not difficult to attract the right people across the sector” says Rob. “They appreciate our type of working environment which ensures they are recognised as individuals.”

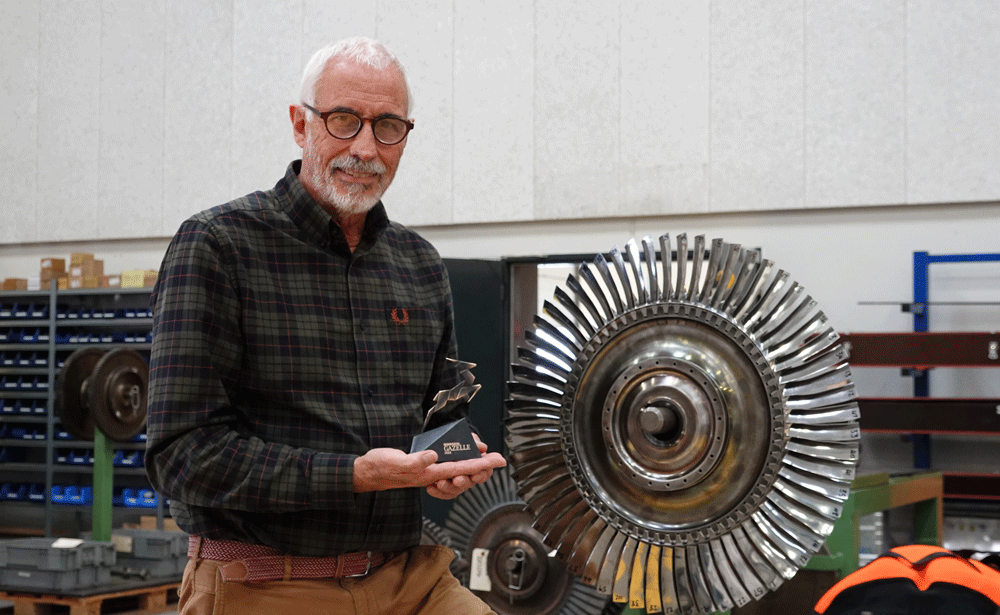

This growth has seen Gas Turbine Services receive the Borsen Gazelle Award for continuous growth and doubling of turnover and gross profit over the past four years. “It’s recognition of the difficult task of doubling our business over four years. We’re very proud of this accomplishment,” Rob says.

Whilst this growth is a huge achievement, Gas Turbine Services is not complacent, they are very conscious they operate and compete alongside one of the large manufacturing giants, however, with their specialist knowledge, personalised and individual approach, Gas Turbine Services are holding their own and indeed, successfully growing their market share, winning over new customers year on year.

“Encouraging the customer to change supplier is the biggest challenge, but when they do join us, and realise how important they are to us, they never go back,” Rob says.

Gas Turbine Services is committed to being able to compete on every level. Its £10 million investment in the multi-engine, multi-fuelled, full-load test facility equals and surpasses anything available to the market.

“Gas Turbine Services built a 21st century facility that lets customers remotely witness engine tests in real time,” Rob points out. “We have invested time, money and effort, coupled with a common-sense philosophy. We do it properly, allowing us to compete for customers whose expectations are high and where engine test, is paramount.”

Gas Turbine Services has seen an extended period of growth. To support this, they are expanding their UK facilities and capabilities having secured their new 1,200 m2 Teal Park workshop in Lincoln.

“We have a growth plan, and it is a strategic one as we maintain and grow the business in a sustainable way,” Rob says. “Continuous rapid growth isn’t healthy. We benefited from a failed competitor and the post-Covid environment and for the time being, we are content with our approach to more gradual organic growth, meeting our commitments and delivering what we promised to deliver.”

“No one knows what lies ahead and what opportunities may emerge in this very specialised and bespoke part of the gas turbine world. Old markets will develop, and new markets will evolve” Irrespective, Rob says, “Gas Turbine Services will be there to meet whatever challenges and opportunities arise, every step of the way”

It seems this unique blend of British and Scandinavian know-how, work ethic and good old-fashioned common sense has a long way to go yet!