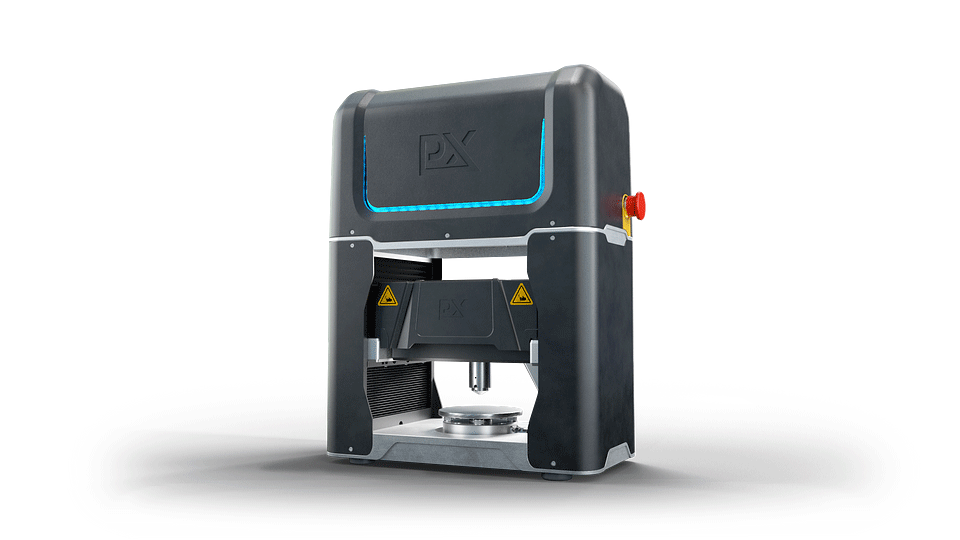

The PLX-Benchtop by Plastometrex. This device uses the PIP mechanical testing technique.

In a significant move to streamline mechanical testing and enhance material insights, Airbus, the global aerospace leader, is collaborating with Plastometrex to support the standardisation of PIP (Profilometry-based Indentation Plastometry) – the innovative mechanical testing technique developed and commercialised by the Cambridge-based technology provider.

Traditional tensile testing requires test pieces that conform to precise dimensions, which adds significant expense to testing workflows, can limit the speed of a project, and can prohibit testing in various circumstances, including where samples are small or irregularly shaped.

Comparatively, PIP sample preparation is simpler, the test operation is more straightforward, and the entire process can be completed in just a few minutes, from start to finish. Also, it can test specimens directly and at a fine scale, which unlocks the testing of small or irregularly shaped pieces and enables the extraction of more data, delivering deeper insights into material behaviour. For example, 160 PIP tests can be fitted onto a standard ASTM E8 tensile coupon, unlocking information about material homogeneity that would be obscured by the single stress-strain curve obtained when tensile testing this part. Through PIP, Airbus will therefore not only accelerate testing workflows but also enable the generation of richer data, supporting innovation and advancing the highest levels of safety in aerospace engineering.

Dr. Jimmy Campbell, CTO at Plastometrex, had this to add about the collaboration: “We are thrilled to collaborate with Airbus on standardising PIP. This partnership highlights the transformative potential of our technology, enabling faster, more versatile, and data-rich testing. Together, we’re setting a new standard in mechanical testing that aligns with the rigorous demands of the aerospace industry.”

This collaboration between Airbus and Plastometrex marks a significant advancement in mechanical testing, offering a streamlined, cost-effective, and data-rich complement to traditional methods. As both companies work together, this new approach promises to improve testing efficiency and deliver more detailed insights into material behaviour, benefiting aerospace projects worldwide.

About Plastometrex:

Plastometrex are world leaders in obtaining stress-strain curves non-destructively, and in providing fast and insightful mechanical testing solutions. Established by former University of Cambridge scientists, Plastometrex combines deep expertise in materials science with advanced numerical modelling and optimisation methods to create next-generation materials testing solutions.

They help companies, universities, and research institutions gain an in-depth understanding of the mechanical properties of their metallic components and materials in a fraction of the time and cost of conventional testing methods. Plastometrex testing solutions are based on an underlying platform technology called Profilometry-based Indentation Plastometry, also known as PIP. The technique enables full stress-strain curves and metal strength parameters to be obtained from a single indentation test in just a few minutes.

To learn more, visit the company’s website or follow them on LinkedIn and X (formerly Twitter). www.plastometrex.com