Based in Enfield, north London, TG Lynes celebrated its 110th anniversary two years ago, an important milestone and testament to its long-lasting dedication to serving the trade for both domestic and commercial applications, while focusing on quality and integrity.

The foundations of the company were laid by Thomas George Lynes, a carpenter and engineer who launched the business in King’s Cross in 1885. Under his son’s management the business became a builders’ merchant and ironmonger and continued to grow rapidly. In the 1930’s the company was incorporated as T.G. Lynes & Sons Ltd.

Managing Director Andrew Ingram explains that nine years ago, the company was acquired by Grafton Group, which significantly strengthened the company’s position. “We enjoy strong support from our parent company for the endeavours that we want to develop with regard to sustainability and site enhancement, while continuing to operate as a self-accounting business.”

Efficient one-stop-shop

Efficient one-stop-shop

The company stocks industry-leading brands and supplies thousands of products including valves, steel and copper tubes and fittings, press systems, composite and plastic plumbing, drainage solutions and support systems and tooling.

TG Lynes premises in Enfield include a modern 60,000 sq. ft. warehouse facility and a 2,000 sq. ft. trade counter. This footprint allows the business to hold extensive levels of stock, giving customers the assurance that key products will be available for collection whenever required, and allowing them to get on with their work quickly and efficiently.

Andrew Ingram explains that TG Lynes operates in a very fast-paced and dynamic industry that requires experience, a fast response and flexibility. And this is what TG Lynes can offer. “We have a lot of experience within the business – some of our colleagues have been with us over 30 years, which is phenomenal. We also have immediate stock availability and the ability to supply products where and when our customers want them,” he says.

“Our warehouse operation lies at the core of the business, but all our departments work together, relying on each other, operating successfully as one unit. The trade counter allows customers to arrive and get everything that they need, including from our Plant Hire Dept. In that regard, we can also operate as a one-stop-shop, enabling our customers to order their fittings as well as the tooling to fit them. This not only saves time and money, but also helps reduce the impact on the environment with all items either being delivered through one single vehicle journey or collected together,” he explains.

He points out that the plan is to grow the tool hire service, which today accounts for about 5% of the business. “We are also able to offer a full recalibration and service proposition for some of the tooling, further enhancing our one-stop-shop capability, and making our customers’ lives easier.”

Leading the sustainable way

TG Lynes services cover the south-east corner of London and the home counties on a next-day delivery basis, extending to Norfolk, the Midlands and all the way down to Southampton. Working closely with suppliers is an integral part of that operation, says Andrew Ingram. “We have very close, almost symbiotic working relationships with our suppliers. Our suppliers are clearly fundamentally important to us, making sure we have the right products at the right time, thus helping the continued success of TG Lynes.”

He further affirms that in addition to fast response, sustainability is a main focus for the company, and the business is proud to be driving forward one of the most progressive and forward-thinking sustainability programmes in the heating and ventilation industry.

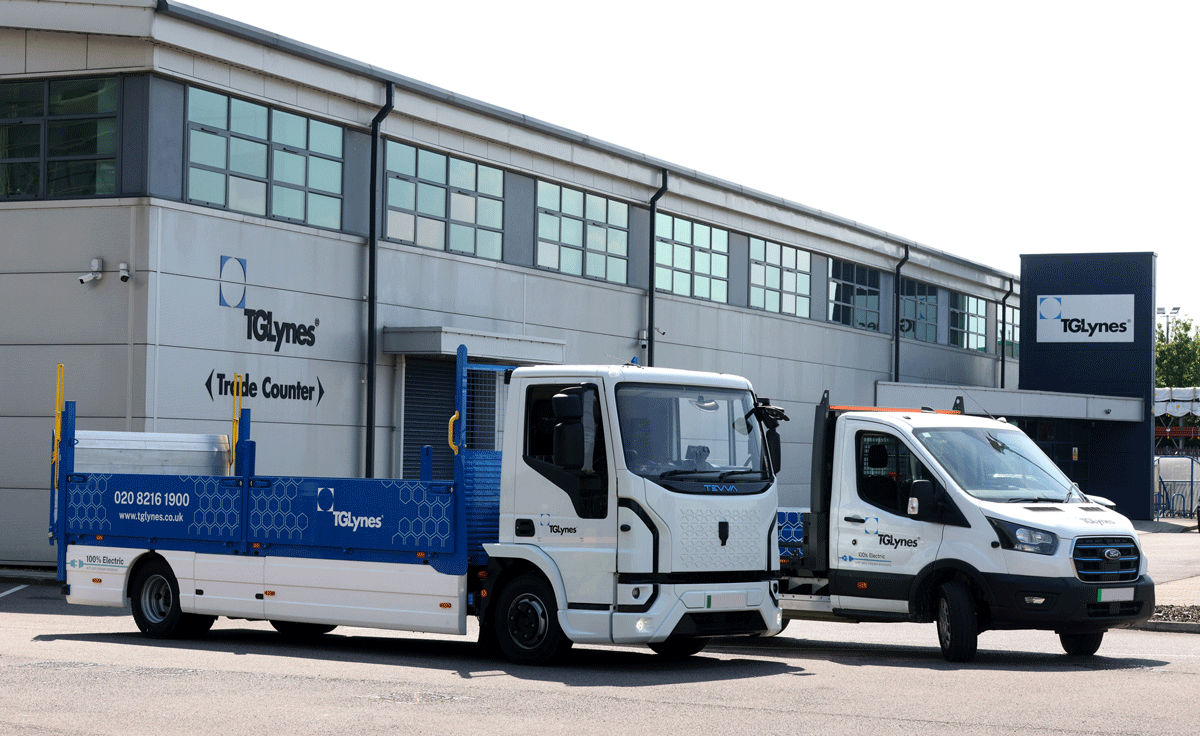

Just recently, TG Lynes became one of the first businesses to operate a 7.5 tonne electric truck on the streets of London, making the company lead the way in the sustainable transport charge. Fully electric 7.5 tonne trucks are just entering mass production and there are only a few currently operating within London. Out of TG Lynes 22 commercial vehicles, three are now electric, says Ingram, operating in London on a daily basis.

Just recently, TG Lynes became one of the first businesses to operate a 7.5 tonne electric truck on the streets of London, making the company lead the way in the sustainable transport charge. Fully electric 7.5 tonne trucks are just entering mass production and there are only a few currently operating within London. Out of TG Lynes 22 commercial vehicles, three are now electric, says Ingram, operating in London on a daily basis.

The introduction of the battery-electric truck is the latest step on the road to net zero for TG Lynes. Last year the business introduced low-carbon Hydrotreated Vegetable Oil (HVO) vehicles to its 18 & 7.5 tonne fleet, making them 90% more carbon-efficient as they carry out daily deliveries to sites across London, the Southeast, East Anglia, and the Midlands.

The business has also installed a 10,000 litre HVO tank at its base for easy on-site refuelling, along with a new electric dropside van, and invested in a 110kW solar system on the roof of its headquarters, providing more than 50% of the energy required for operations. Furthermore, all imported electricity comes from 100% certified renewable sources. “So, while we strive to operate as efficiently as possible, everything is geared around reducing emissions directly and indirectly,” says Ingram.

Expanded business.

He affirms that as the business is expanding, environmentally friendly operation will remain a priority. “We are taking decisive action to ensure we are doing everything we can to lower our impact on the environment. Sustainability is not just a buzz word for TG Lynes – it has authenticity. And we do not rest on our laurels. We continue to review our policies at intervals to make sure we can make further gains, such as in recycling.”

In concluding, Ingram acknowledges that investment in enhancing the physical elements of the Enfield site also continue. “A few years ago, we installed a new mezzanine floor which is now fully utilised, and we have also started to utilise vertical expansion with high-level storage options. The next stage is another warehouse extension project which should begin early next year. This will bring us another 7,000 sq. ft. This is exciting, as having more space simply allows us to expand our portfolio and further improve the service to our customers.”