Headquartered in Southport in the UK, the Lattimer Group covers four operating companies in the UK, US and Germany which manufacture around 15,000 different components for container glass manufacturing plants located around the globe.

The precision-machinist has been at the forefront of setting standards in glass engineering for over four decades, and its continued commitment to producing new products in partnership with customers has ensured that the company has remained the market leader in the supply of IS variable equipment for the glass container forming industry.

Carl Stead, Finance Director at Lattimer Group, describes the environment in which the company operates: “Ours is a very niche sector of engineering parts for the global glass container industry; 80% to 90% of those containers will be alcohol-related, but can include anything from food jars and medicine jars to perfume bottles.”

“In glass container making factories located around the world, molten glass is processed on IS machines that churn out thousands of containers every hour. This machinery collectively has thousands of moving parts, and whilst we don’t make the machines themselves, we make thousands of those moving parts.”

Precise, long-lasting, reliable

A typical container plant furnace will melt around 300 tonnes of glass per day and produce in the region of 50,000 bottles or jars per hour, depending on the size of the containers. The glass in the furnace cannot be allowed to cool or set, and so production has to be a continuous process – 24 hours per day, 365 days of the year.

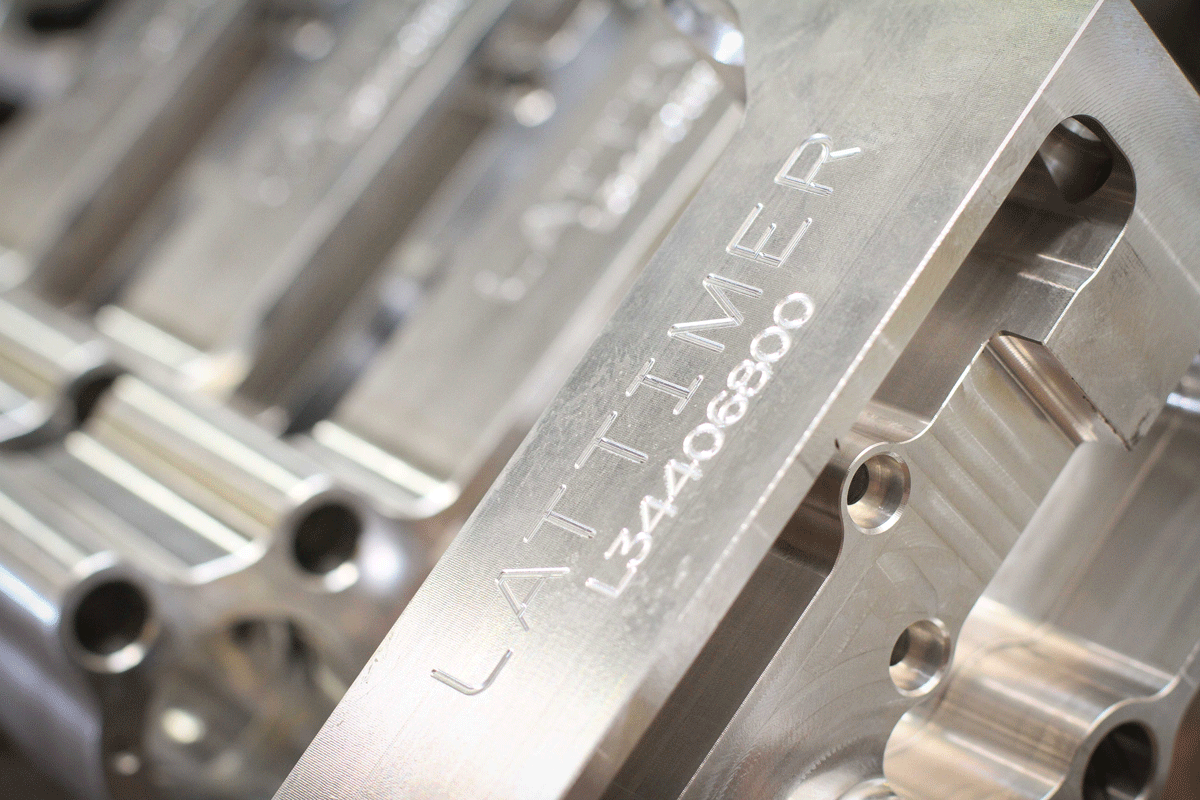

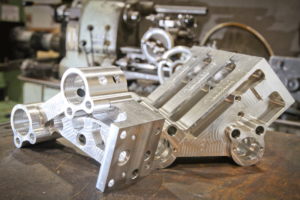

“Molten glass is quite abrasive so even though our parts are made of iron, aluminium or stainless steel, they still wear out and need replacing constantly. They may wear out by only a tiny fraction but as those thousands of parts are all connected together, and many of those are made by different companies, precision is key. That is why our manufacturing is classed as precision engineering – the parts must fit in exactly like a jigsaw puzzle,” explains Stead.

“Given the nature of the production, customers’ requirements are very specific – they are looking for parts that are exact, precise and fit with minimal issues, that last as long as possible, and that can be replaced very quickly, in minutes rather than hours. Another aspect that is important to customers is timeliness of delivery – as any downtime is very expensive, a high degree of certainty is needed that the part will arrive at the required time.”

Bespoke production

Bespoke production

Lattimer meets all of those requirements, which, combined with its decades-long expertise, makes the company a sought-after partner for glass makers around the globe – almost 90% of Lattimer’s output is exported to over 70 countries, says Stead.

He further points out that Lattimer does not engage in mass production. “Typically, the batch size of one particular part would only be 12 or so, as it will only fit in one particular type of machine in a particular factory. In a typical year, we would make around 3,000 or 4,000 different parts. We rarely produce for stock; the parts are normally made to order. As such, our production is very bespoke and very specific. Often parts need to have their design changed to fit modified factory set-up or new environmental conditions, so variety is a constant in our operations.”

For this type of production solid, long-term relationships with raw materials suppliers are key, and Stead affirms that most of Lattimer’s suppliers are located close to the company’s factories to minimise lead times. “Given our small batches, close relationships with our suppliers are vital to make sure that they can accommodate our requirements within their bulk material orders for larger customers.”

Solidified presence

Over the last few years, Lattimer has significantly expanded its footing. In 2022, the company acquired Hunprenco, the world’s leading manufacturer of plungers and coolers for the glass container manufacturing industry and last year, Hartmann and Bender, a German manufacturer of IS variable equipment, joined the group, extending Lattimer’s presence to Germany.

“Hunprenco specialises in a particular range of parts that we don’t produce elsewhere so the acquisition expanded our product offering. With Hartmann and Bender, we acquired our competitor, boosting our position in mainland Europe and easing trade with our European customers post-Brexit. The acquisitions have enhanced our portfolio – no other company in the world can offer the same breadth of parts that we engineer.”

Lattimer is committed to continued investment and already boasts an on-site training academy and access to the latest CNC machine technology and facilities. “We bought three new CNC machines over the last eight months, and also invested in our first cobot. We are also going to replicate the state-of-the-art automated pallet system used in our German facility and have just ordered a similar system in the US.”

Consolidated business

Consolidated business

Stead reflects that demand for glass containers is steadily increasing, by around 3-4% each year on a global scale, and not only as a result of the push for sustainable materials. “Glass container manufacturing is a relatively robust sector regardless of recessions or fluctuations – everywhere around the world people still need to drink. Also, as countries develop economically, people naturally drink more alcohol, so the amount of glass containers within those countries increases as well.”

In the light of these developments, Lattimer seems to be in the right place at the right time. Carl Stead agrees: “Today Lattimer Group is a £30 million business, employing 220 people across three separate countries. With our recent acquisitions, we have doubled the size of the business over the last two years.”

He concludes that the plan for the near future is to consolidate the new businesses, making use of their synergies, and focusing on the right integration of the product range in all factories.” Although our four production facilities are independently run, we encourage constant communication between them to see where each particular part can be made most efficiently. Consolidation of all businesses so that we all work better together is what we are focused on right now.”