Hungary-based Ganz has yet again recorded a highly successful year despite the inflationary environment and geopolitical challenges. Located 80 km from the Hungarian capital, the company is continuing the legacy of the business founded in Budapest by Ábrahám Ganz in 1844, that boasted several world-first inventions introduced in the late 19th century, including the first high-efficiency, closed-core shunt connection transformer launched in 1884.

Four years ago, the company entered a new era, re-establishing its former leading position after a change in ownership and a subsequent business turnaround. “We are proud to be Europe-based and Europe-focused; and our recent investment in technologies and environmental improvements have helped us to grow our reputation,” says Jan Prins, Chief Executive Officer of Ganz Transformers and Electric Rotating Machines Ltd.

Sought-after partner

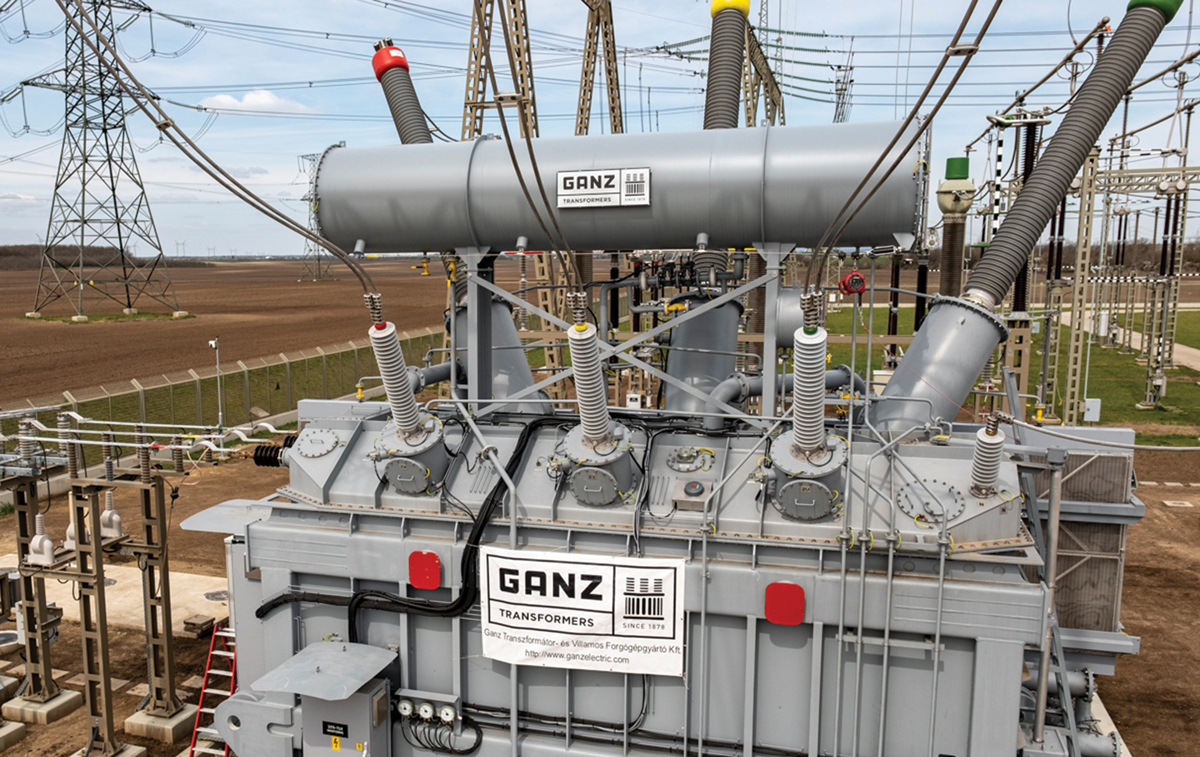

The company today manufactures custom-made high-voltage electrical equipment, including power transformers, motors, and generators, and provides related service activities for its customers at its plant in Tápiószele. With its more than 550 people, Ganz is one of the largest employers in the region.

We spoke to Jan Prins last year when the company commemorated its 145th anniversary and he affirms that the celebration of this important milestone was a huge success, fully confirming the return of the Ganz brand to the European market.

All four of the company’s divisions – Transformers; Rotating Machines; Service; and Intelligent Solutions – are growing. Transformers are still the largest product group, but the other divisions are catching up, with the Rotating Machines division expected to double output as a result of new orders from international companies across a wide range of sectors.

All four of the company’s divisions – Transformers; Rotating Machines; Service; and Intelligent Solutions – are growing. Transformers are still the largest product group, but the other divisions are catching up, with the Rotating Machines division expected to double output as a result of new orders from international companies across a wide range of sectors.

The Intelligent Solutions monitoring systems, developed for transformers in 2022, are now applied across Ganz’s product range and represent a significant competitive advantage for the company. They provide continuous real-time monitoring of asset health through centralized interface, thus saving maintenance and repair cost and extending machine service life. “Last year, we opened a dedicated training centre for Ganz Intelligent Solutions, for customers to see the system working in real applications,” says Prins.

He points out that the Service division has recorded marked growth as well. “Maintenance and servicing are becoming more important in the energy sector. Since 2023, Ganz has had a dedicated refurbishment hall, which allows us to bring a transformer to the factory and carry out complete refurbishment. Depending on the complexity of the refurbishment, the lifespan of the refurbished transformer can be extended up to 10-15 years.”

Investing in growth

Looking back, he affirms that Ganz growth since its re-start has been unparalleled, establishing a benchmark within the industry. “We have confirmed our position as a market leader within the renewable sector both in Hungary and internationally, and our Ganz Intelligent Solutions success has been exceeding expectations. Coupled with our customer-centric approach, we have become a preferred supplier to major European companies.”

Last year the company increased staff numbers by 20% and reinforced the foundations for further growth. Its internal focus on sustainability has remained a key topic, as demonstrated by the construction of a 2 MW solar park at its Tápiószele site, to be implemented within Ganz’s Energy Optimization Programme worth some €11 million. “Once completed, 80% of the Tápiószele plant’s energy needs will be met from renewable resources,” says Prins, adding that the company plans to reduce its carbon emissions by almost 40% by the end of 2024.

The modernisation of assets has also remained to the forefront. €3.8 million has been invested in Ganz Metal Works Ltd. plant in Szolnok, focused on the assembly of transformer external steel structures. This will enable the company to integrate a new element of the value chain, further improving competitiveness and security of supply. “The reopening of Ganz Metal was critical to secure the supply of external structures, as this is one of the most critical items in the transformer supply chain at the moment,” says Prins.

In the early 2024, the company launched a €12 million project focused on technology development in its Rotating Machines (RM) division, aimed at transforming the factory into a modern manufacturing facility.

“The investment will allow the RM division to align with the overall company strategy of supporting the net zero targets set by the EU; the focus has shifted to meeting the needs of the renewable energy sector, primarily with solutions for hydroelectric power generation and energy storage,” Prins explains.

“The engineers in Ganz’s Rotating Machines division have the high level of knowledge and technical expertise that gives them a strong advantage in the race to win new orders. The team members view each individual order as a new professional challenge. This enables us to produce customized machines that other companies cannot build, and this is the key to our competitiveness.”

Record breaking year

Record breaking year

Looking ahead, Prins affirms that Ganz will continue to be a 100% European company – ‘bought and made in Europe’. “This means that our supply chain is also European.”

For example, the company has been working with the Weidmann Group, a leading integrated solutions provider for specialized product and services in the energy sector that has been at the heart of the global transformer industry for almost 150 years.

“We have excellent relationships with our suppliers, which will be further strengthened based on our long-term commitments towards them in line with increasing order numbers.”

As such, Ganz is facing a busy year ahead and plans to further increase staff numbers. “In addition to scheduled investments, our priorities for the coming year include further improvement of the facilities and continuing the digital transformation. We will start working on the Ganz Xpert system for Ganz Intelligent Solutions and continue to develop the Service division with a focus on refurbishments, as an attractive alternative to new supplies that have long lead times,” says Prins, outlining the imminent tasks.

“Needless to say, Ganz will also continue to work on sustainability, with our ESG report being issued in May, and pushing activities aimed at reducing the carbon footprint of our production facilities.”

In concluding he affirms that 2024 is expected to be a record-breaking year for Ganz, both in term of output and financial results. “We will continue to develop the Ganz brand in export markets, with a focus on “new” renewable sectors such as hydro, pump storage and network stabilization solutions. We are in discussions with our owners about additional investments which we plan to announce in the coming months. This may not only expand production capacity but also potentially open gateways to new markets.”