From varnish and sealants up to lubricants: Whenever users in industry want to pump large quantities of highly viscous media, they run the risk of altering the quality and integrity of the pumped liquids. Lutz Pumpen has developed the solution to this problem. Its new TR series wobble plate pumps enable the sensitive pumping of up to 30,000 litres of highly viscous liquids per hour. This new development will be on display at Achema 2024 (hall 8, stand K86), the world’s leading trade fair for the process industry, held in Frankfurt am Main from 10 to 14 June 2024.

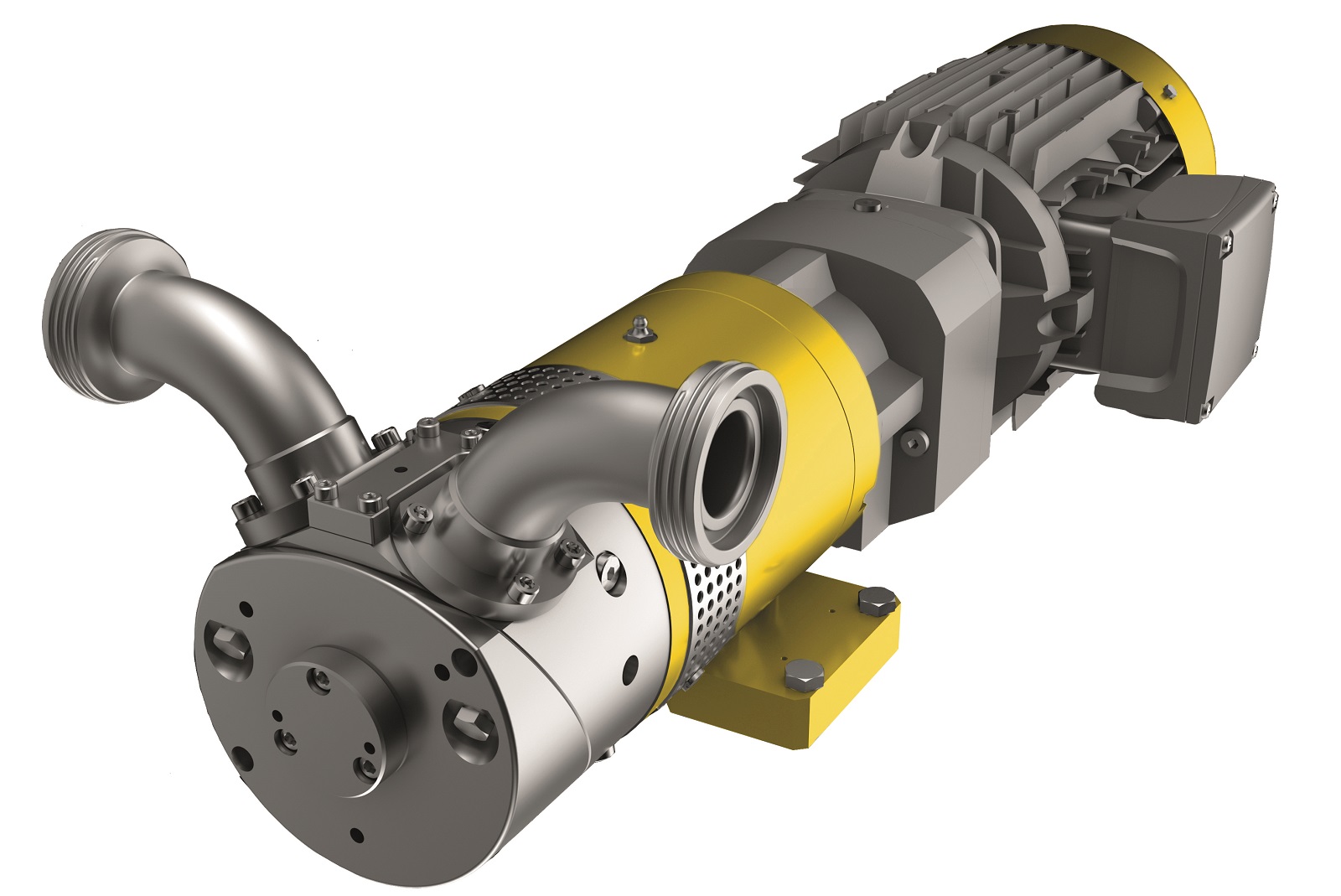

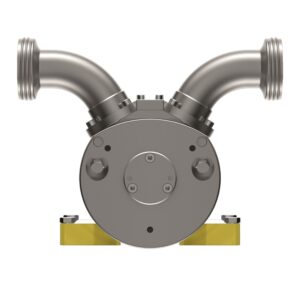

The TR series wobble plate pumps make use of a tried-and-tested principle: a spherical pump housing accommodates a wobble plate that sits at an angle on a shaft. The rotation of the shaft causes the plate to perform a characteristic wobbling movement. It continuously changes the volume of two chambers on both sides of the shaft. This creates alternating positive and negative pressure, which draws liquids into the pump and expels them through an outlet opening. An efficient principle that has proven itself with highly viscous liquids such as oils, lubricants, varnish, sealants and silicones. “The new TR series wobble plate pumps from Lutz Pumpen offer a high-performance solution for industrial applications in which high flow rates at high viscosity pose a challenge,” says Heinz Lutz, Managing Director at Lutz Holding. “The new industrial pumps pump up to 30,000 litres of thick or viscous liquids and media containing solids with a viscosity of up to 1,000,000 millipascal seconds and a temperature of up to 205 °C.” The new wobble plate pumps, which are made of robust stainless steel, are suitable for application in a range of industries including the paint and coatings industry, the sealants and adhesives industry, the pharmaceuticals industry, the cosmetics industry, the oil industry and the food industry.

Maintaining the quality and integrity of the pumped media at high flow rates

The new TR series wobble plate pumps are characterised by their sensitive handling of sensitive products. “Many companies working in an industrial context have found that even expensive systems have a negative impact on the quality and integrity of high-viscosity media when pumped at a high flow rate,” says Lutz. To address this problem, the design of new pumps placed a particular focus on sensitive product handling. “The special design of the wobble plate pumps means that they generate a continuous and almost pulsation-free flow, which is subjected to only minimal shear forces. There is no crushing whatsoever. In addition, their compact design minimises the contact time between the medium and the pump. This ensures that the quality and integrity of the pumped media are maintained.” This was demonstrated in a range of applications, including the work of a company that produces shampoos with integrated air bubbles. Conventional pump systems that produce high shear forces would have caused the tiny bubbles to combine into larger air bubbles. “With pumps from the new TR series on the other hand, the original product properties are retained.”

particular focus on sensitive product handling. “The special design of the wobble plate pumps means that they generate a continuous and almost pulsation-free flow, which is subjected to only minimal shear forces. There is no crushing whatsoever. In addition, their compact design minimises the contact time between the medium and the pump. This ensures that the quality and integrity of the pumped media are maintained.” This was demonstrated in a range of applications, including the work of a company that produces shampoos with integrated air bubbles. Conventional pump systems that produce high shear forces would have caused the tiny bubbles to combine into larger air bubbles. “With pumps from the new TR series on the other hand, the original product properties are retained.”

“For many companies, fast maintenance is decisive in a time of skills shortages”

The TR series impresses not only with its high performance and sensitive product handling, but also enables effortless integration into existing process landscapes. With units ranging in length from just 316 to 440 mm, users have the flexibility to mount them horizontally or vertically. The pump head can be rotated in 90 degree increments to allow easy adaptation to existing pipework. The series provides a range of mounting systems such as flange, milk pipe, TriClamp and Camlock. “We have also worked to ensure that the TR series wobble plate pumps are low maintenance and can be cleaned easily, even after connection of pipework. This is crucial for many companies, especially in times of skills shortages,” says Andreas Rössler, Sales Manager at Lutz Pumpen. “Simply dismantling the pump head means that cleaning and maintenance work, such as replacing the wobble plate or shaft seal, can be completed within ten minutes. This ensures increased availability and greater productivity.”

The TR series wobble plate pumps are available in three versions: The TR015, an entry-level version, operates with a 3 kW motor, 10 bar pumping pressure and achieves a flow rate of 6,000 litres per hour. The TR030 has a 5.5 kW motor and works with a flow rate of up to 12,000 litres per hour at a pressure of 15 bar. The TR080 – the Goliath of the series – achieves an output of up to 30,000 litres per hour with a 7.5 kW motor at a pressure of 15 bar. Lutz Pumpen also offers several wobble plates for specific industry requirements – such as FDA-compliant versions for the food and pharmaceutical industries and aluminium bronze versions for the petrochemical industry.

About the Lutz Group: Pioneering fluid management since 1954

Established in 1954, the internationally active family business Lutz has advanced to become synonymous for professional fluid management. Today, the Lutz group of companies includes a number of top-performing, medium-sized companies located in Germany and abroad, which operate in the broad field of pump technology, water treatment and disinfection. The Lutz Group has 13 branch offices and representatives in over 80 countries.

The high-quality and reliable pumps, systems and accessories are deployed for dosing, conveying, emptying and mixing a wide variety of media from containers and in systems and processes. The product range includes drum and container pumps, flow rate meters, double diaphragm pumps, centrifugal pumps, solenoid and motor-driven dosing pumps, gas dosing devices, measurement and control systems and disinfection systems for industry and swimming pool water.

Corresponding with the broad range of services provided by the Lutz Group, the products and solutions provided by its companies are deployed in a wide variety of industries and commercial sectors. Leading examples include the chemicals industry, the automotive and vehicle industry, electroplating and surface treatment, the food industry, the paint and varnish industry, agriculture, water and wastewater treatment and the paper and ceramics industry.