TECO 2030, a spin-off from TECO Maritime Group that has provided technology and services to the global shipping industry for decades, was founded in 2019 with a clear goal – to make the world greener.

The company has been active in several areas, including emission reduction systems such as exhaust-gas cleaning systems for ships, but its biggest focus is currently on developing hydrogen fuel cells, a breakthrough technology primarily, but not only, for the maritime industry.

“A fuel-cell module is the next generation of engines and power generators, where hydrogen is the fuel,” says company CEO Tore Enger. “The fuel-cell powertrain and hydrogen are the only pathway to zero emission.”

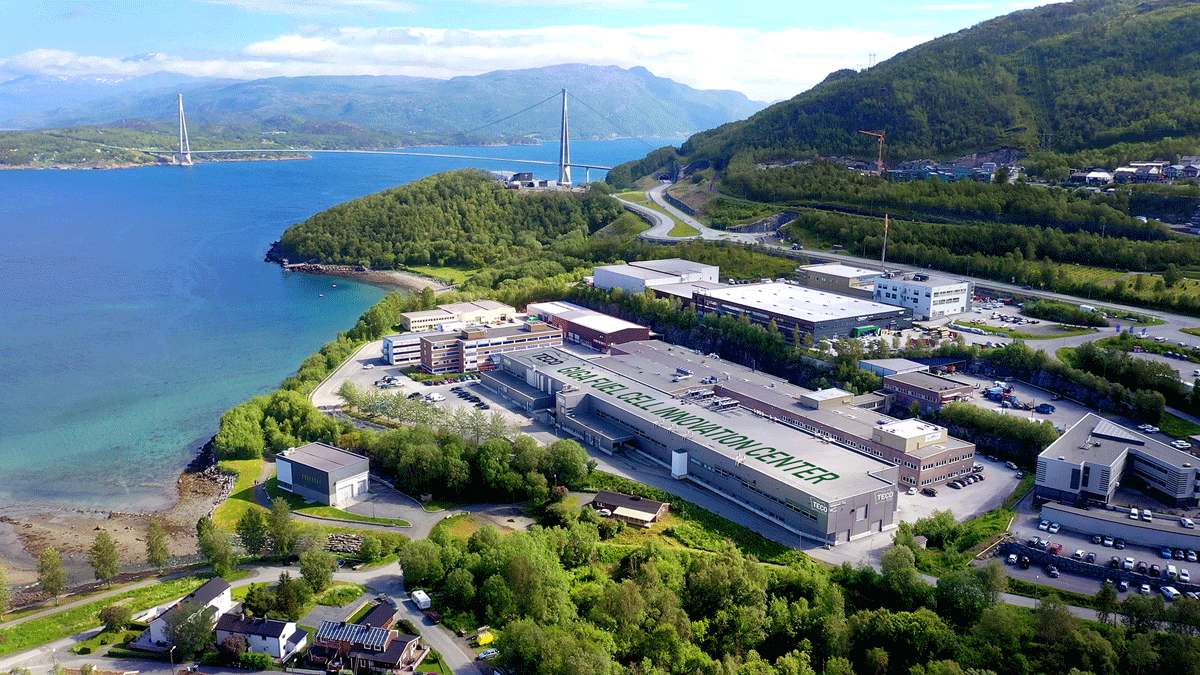

We interviewed Enger two years ago and spoke about TECO building Europe’s first giga factory for hydrogen proton exchange membrane (PEM) fuel-cell stacks and modules at its Innovation Centre in Narvik in northern Norway. The company is on track to build up production capacity through 2024 and 2025, targeting an output capacity of up to 200 MW of fuel cells in 2025, 600 MW in 2025 and 1.6 GW in 2030.

Key milestone achieved

Key milestone achieved

Now Enger has confirmed that the company has just reached yet another milestone on its journey towards its mission – in November 2023, TECO has successfully injected its fuel cell system with hydrogen in the AVL facility in Graz, creating emission-free hydrogen-electric power, with a view to reaching customer deployment in second half of 2024.

The innovative 400kW module represents the most compact and energy-dense system available for marine vessels and other heavy-duty equipment. Its attributes include industry-leading energy efficiency, an inherent safety concept, leading weight/size dimensions and component design, lifetime, and rapid dynamic load response. By 2030, the target is to produce 4,000 units per year at TECO’s giga factory in Narvik.

“We are quite simply developing the engine of tomorrow,” Enger affirmed. “Operating one FCM400 unit instead of a diesel generator saves our planet from over 9000 tons of CO2 emissions – or consuming over 3.5 million litres of diesel during 35,000 hours of operations.”

“Our FCM400 system has officially been tested with hydrogen and produced electricity as expected and the performance data collected demonstrate how we have met or outperformed our own expectations,” he continued. “The road to a better and more sustainable future is becoming clearer and clearer to us as we reached this enormous milestone in our company’s history.”

The right chemistry

He further affirmed that the company has chosen leading global companies as partners on this quest, such as thyssenkrupp, which is supplying and installing the production line; and AVL, a forerunner in hydrogen powertrain application development, to validate the stack and system technology for heavy-duty applications. “We wanted to have the very best team to create the best product with minimum risk,” he said. “It’s all about chemistry. If the chemistry is right, then amazing things happen.”

So, they have. Now, the module is standing in the testbed and the stacks have already been tested for more than 3000 hours. “The module is producing electricity from hydrogen. This is a huge achievement with more than half a million manhours behind it,” Enger noted, adding that the launch in Graz was attended by many potential clients, stakeholders, shareholders, investors, and potential investors, waiting to see the biggest and most powerful fuel-cell module ever made.

The system will undergo further testing, with the intention of deploying the first system for the end of 2024. The manual production of FCM400 systems will continue at the technology development partner AVL in Graz for the next few units before moving production to Narvik, Norway during the first half of 2024. The Narvik site is already well underway with manual production of fuel-cell stacks.

Moving to mass production

Moving to mass production

As the world accelerates towards decarbonisation, demand for fuel cells is set to increase steeply. “Our potential fuel-cell projects represent about €1.35 billion in quotes as of October 2023. There are 118 million diesel generators in the world and all of those need to be replaced within the next 10 years,” noted Enger.

The company currently has over 120 active projects in the pipeline, including the biggest ongoing hydrogen fuel-cell retrofit of a bitumen tanker, set to enter zero-emission service late 2025; and the fuel-cell power generator for a construction site to be delivered in late 2024. Just recently, TECO signed a partnership and investment agreement with Yokogawa, a Japanese multinational electrical engineering and software company, for the utilization of hydrogen fuel cells in industrial applications.

Regarding suppliers, Enger acknowledged that TECO has secured its value chain for the next two to three years, which is also the timeframe from starting and moving towards mass production. “The suppliers will be an integral part of our growth, as this emerging industry opens up many new opportunities.”

Speaking about the current market environment, he pointed out that the shift towards zero-emission technologies is accelerating, although maybe not as fast as some predicted earlier. “We plan to produce 1.6 gigawatts of fuel cells in Narvik by 2030. But according to Citigroup and McKinsey, the global market will need 50 gigawatts annually by that time, and this number will grow significantly in the years to follow. Even if we reach our goal of 1.6 gigawatts, which can be increased to 3.2 in a 24/7 operation, there will still be an enormous need in the market.”

“Our system is a standard and fully customizable fuel-cell system that can be used in various applications such as marine main or auxiliary engines, construction sites, stationary shore power applications and other energy intensive applications. TECO 2030 is at an exciting pivotal point in its development and is continuously looking for new potential partners, employees, and investors to work with, so we together can realize a common zero-emission future,” Enger concluded.