Yaskawa UK offers best-in-class robotics solutions for the UK manufacturing sector, distinguishing itself not just through its products, but through its customer service and after-sales support. It is a company that has built a reputation by staying close to its customers while offering them an outstanding portfolio of automation technology.

“Yaskawa was founded in Japan in 1915, and ever since then we have developed and utilised all of our own technology,” says Jonny Grey, UK sales director of Yaskawa UK. “Within the robotics sector, we have a large scale, global Research and Development team, and we invest a lot of money in new products.”

Of course, in 1915 the word “robot” would not be invented for another five years. Back then Yaskawa was a motor company. Then it moved into the servo drivers’ market in the 1970s, and not long after that it developed one of the first electric robots, coining the term “mechatronics” in the process.

But while Yaskawa UK has made its name in robotics, it is also a business that understands the true value of human resources.

“We are very proud of our extremely low turnover of staff,” Grey says. “That speaks volumes about our organisation. We view our people as our biggest asset, and we are willing to invest in those people.”

Nurturing a Passion for Robotics

Nurturing a Passion for Robotics

But while Yaskawa UK invests in the people it already has, it is also more than aware of the importance of maintaining a pipeline of new talent. Yaskawa UK is always looking for new people for its sales and technical services. But here Yaskawa UK faces some unique challenges relative to the rest of the international robotics industry, and even the Yaskawa Group as a whole.

“People are challenging to find in the UK because for many decades manufacturing and engineering have not been seen as attractive,” Grey says.

The key, Grey believes, is to show people just how exciting the latest technology in the field is.

“Once people can get their hands on this technology and interact with it, you can see their eyes change,” Grey says.

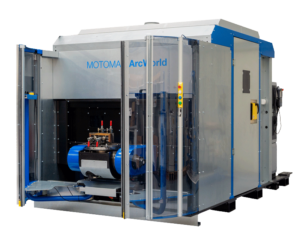

Right now, that technology is being demonstrated through a brand-new facility that Yaskawa UK has just opened. The new building covers 35,000 square feet, taking the company’s centre of operations from Banbury in Oxfordshire to Washington, near Sunderland.

“It is where our best assets are in terms of where people are located, and it is also our biggest regional growth area in the UK,” Grey says, reminding us Yaskawa UK likes to be close to its customers.

The Inevitable Future

It is a facility that will show new recruits the potential of the automated manufacturing sector.

“They can see that this is the future. Automation is the future, whether people come along with it or not,” Grey tells us.

Grey says, “or not”, because unusually, the UK’s manufacturing sector has been somewhat reticent about adopting automated tools.

“Robotics and automation have seen spectacular growth globally, but the UK is very much lagging behind,” Grey tells us. “The UK has a strong manufacturing history, but right now, even though we are the ninth largest manufacturing nation in the world, we rank 24th in our adoption of robotics and automation.”

Climbing those rankings, and getting manufacturing to invest in robotics and automation, is Yaskawa UK’s fundamental challenge. To do that, it has to overcome some deeply ingrained British habits and ideas.

“There is a reluctance to make long-term investments, to lay out large capital investment for a long-term gain,” Grey points out. “If we look at our European competitors or partners, they will do that. There is also, historically, a bit of a ‘make-do and mend’ mentality in UK manufacturing. If a piece of equipment has functioned well for decades, people will tend keep it for as long as they can.”

Grey contrasts this with the industry in places such as Germany, the biggest user of automation in Europe, where the focus is always on investing in the latest and greatest technology that can make a business more efficient and competitive.

At the same time, Grey points to industry in China, a country historically known as a land of cheap labour, but today only Japan and Korea are ahead of it as the largest users of automation in the world.

To try and shift the needle in the UK further in that direction, Grey is passionate about pushing the benefits of automation to manufacturers through seminars, informational videos, and sales visits.

“We can go out and extol the virtues, but it takes two to tango,” says Grey. “We need the manufacturers to get on board.”

Grey makes a strong case for the role of automation in the industry. Once again, it ultimately comes down to people.

“Robotic automation offers quality and repeatability,” Grey says. “It allows you to better utilise your assets, and most importantly, your people. People do not like doing repetitive, boring, or dangerous jobs. Investing in automation can you make a business more profitable and let it redeploy people into more fulfilling roles.”

A Manufacturing Future

A Manufacturing Future

It is a change Grey is convinced the UK’s manufacturing sector will make, and as it does, Yaskawa UK will be there to support them.

“Our future looks very exciting at the moment,” Grey shares. “We are moving into new premises, there is a very strong demand for our products, and we foresee continued growth in both small- and large-scale projects. We have made an investment in Yaskawa UK and will continue to be here to help the UK manufacturing sector be a success.”

If there is one take away that Grey wants to leave us with, it is that enormous potential in the UK manufacturing sector.

“There are so many things on the cards, but the government don’t have a lead for UK manufacturing,” Grey says. “Everything is focused on the service industry. But the only way out of the economic issues that we are seeing as a country is when people make things, physical things that other people want to buy. That is how you grow and develop. We used to be a much bigger manufacturing country than we are now, but the potential is still there. We can be one of the greats.”