Situated in the valleys between Swansea and Cardiff, near the Welsh town of Aberdare, the electronics industry is thriving. Though Aberdare may not be immediately associated with the electronics industry, it has been home to some of the biggest names in the business, such as Hitachi, Lucas Aerospace, and Sony, resulting in a highly skilled local labour pool. Today, the contract manufacturer Philtronics Ltd is carrying the torch and driving the industry’s future.

“Historically, there’s been an abundance of skills in this area,” says Simon Pritchard, CEO of Philtronics Ltd.

The company was established in October 2003 and is now in its 20th year of trading. Calling the company a contract manufacturer is underselling just what Philtronics has achieved.

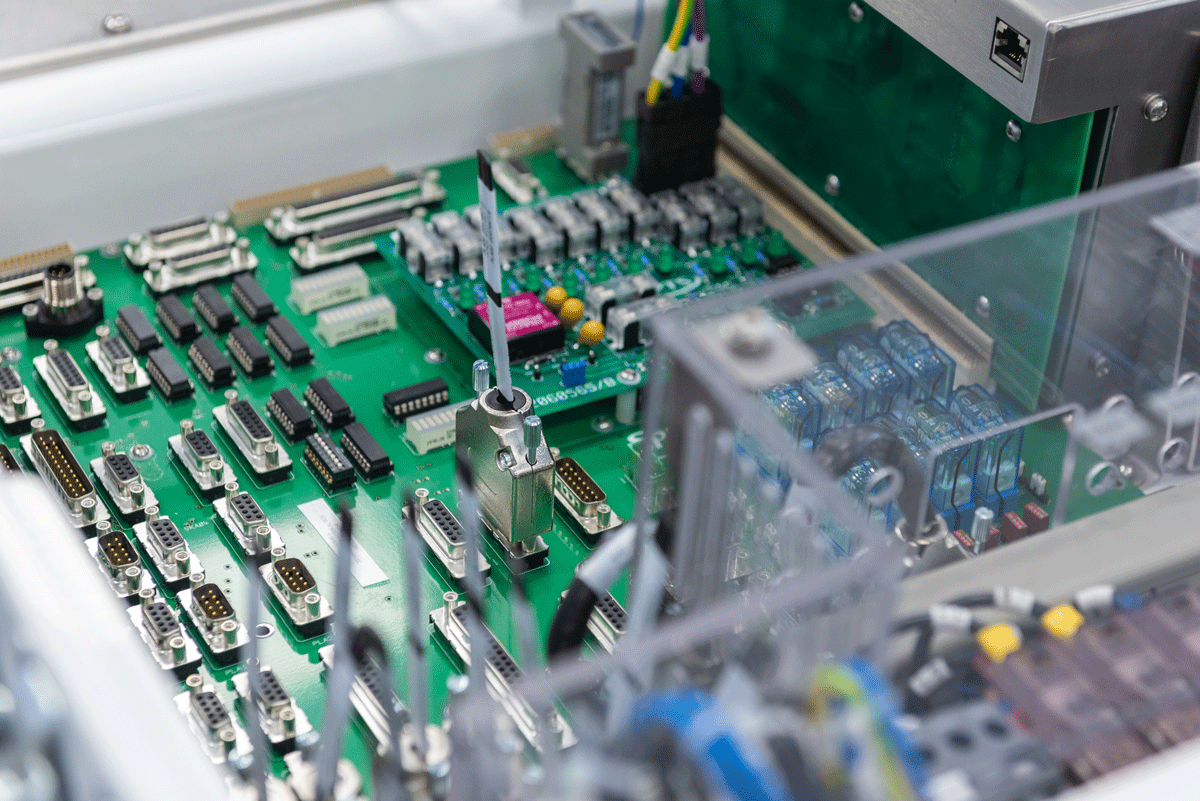

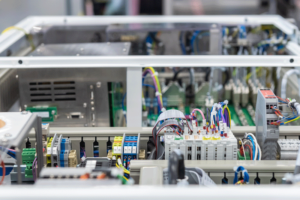

“I didn’t start Philtronics as a PCB assembly company or cable harness manufacturer,” explains Pritchard. “My background is purchasing – I’m a gamekeeper turned poacher. I knew that the market was looking for a full turnkey solution.”

Pritchard is the first to acknowledge that it is not the first PCB assembly company to claim it offers a turnkey solution, but Philtronics is that rare. This company has been designed as a turnkey provider from the ground up.

“We always knew that the further along the supply chain we could deliver material for the customers, the more cost-effective it becomes,” Pritchard says. “The more cost-effective it becomes, the greater the value added.”

The company works with the medical, health, sports, and wellbeing sectors, but perhaps unsurprisingly, the most active market Philtronics is engaged in is the semiconductor market.

Manufacturing Comes Home

Manufacturing Comes Home

As a complete turnkey provider, Philtronics is well-positioned to take advantage of a dramatic change in the UK manufacturing sector.

“For the last 30 years, we have seen a huge push for outsourcing and offshoring as people look for the cheapest prices,” Pritchard tells us. “I knew, as a buyer, that there was this wrong perception that these costs would be a sustainable, cheap alternative. The total acquisition cost does not fit those parameters. So, when it turned on its head, and people began talking about reshoring, we were in a prime position to anticipate what the customer would be looking for.”

Philtronics has been ready and waiting for this change with a fully vertically integrated business structure.

“Where we are unique, aside from making it all in-house in South Wales, is that we have a Class Seven clean room on-site,” Pritchard says. “That has let us branch into sectors around advanced manufacturing. It improves the proposition that we can offer buyers.”

The clean room is vital because, as Pritchard is the first to point out, the sector is one where it takes work for a manufacturer to differentiate itself.

“Contract manufacture and design is standard, so for us, it was about looking for the next step,” says Pritchard. “We installed the clean room to serve semiconductor clients who are paying a premium for manufacturing in the clean room environment, taking lower-level clean room assembly away so they could focus on their IP.”

A Wealth of Talent

The move of manufacturing away from the UK has also had an impact on the communities in the Welsh valleys as well.

“Historically, you would have seen people on this estate on a conveyor belt of training with companies coming to these areas because of the people,” Pritchard says. “When those companies left, they left a hole here, with an established workforce left behind.”

That workforce has proven to be an invaluable resource for Philtronics. With those companies no longer in the region, Philtronics has been able to tap into those demographics ready to work, maximising their strengths and supporting the local area.

In 20 years, the company has grown from a small core team of four or five employees to a team of up to 100 employees.

“We are not a large corporation with the luxury of a million pounds’ worth of resources, so we adapt to what is available around us, and what has always been abundant here is people’s desire to work,” Pritchard says. “The people around here define resilience; they want jobs and careers.”

While there is a concentration of people willing and able to work in this region, Pritchard has seen the challenges of a skills shortage up close and personal.

“In every sector, skills and a perceived lack of skills are a topical conversation,” says Pritchard. “In the early days, it was about looking for people to give skills to. We rarely found an agency or CV that came across our desk that was an ideal fit for us. So, we had to find different ways to approach the problem.”

Philtronics has invested heavily in training and upskilling its people, including apprenticeship schemes through local colleges. As Pritchard shares, the people it has invested in have paid that investment back 20-fold over the years.

But while relationships with colleges are valuable, Pritchard warns against prioritising academia too much.

But while relationships with colleges are valuable, Pritchard warns against prioritising academia too much.

“People talk about needing more engineers, but the business is an ecosystem. We need buyers, admin staff, and accountants. Every role needs upskilling, but it cannot be viewed as exclusively about academia,” Pritchard says. “Most of our staff left school at 15 or 16; many had a bad experience of the school environment and came into a factory because they saw it as the only option.”

Philtronics has taken a long look at its business and where it needs to grow, and it has seen that the best way to upskill its people is not necessarily by recreating a school environment many of its staff have sought to avoid.

“We make sure people understand that a factory job is not the end of the road, and it doesn’t mean going back into a school environment to get on those pathways to progression,” Pritchard says. “My production manager at 16 left school, came here as an operative, and now she’s production manager.”

At the end of January, Philtronics launched the Philtronics Academy, a training facility that actively pushes against the one-size-fits-all approach to training. It is only a part of an exciting next stage for the company’s development.

Last year, Philtronics’ turnover was £15 million. Over the next two to three years, it is expected to reach a turnover of £20 million.

“Every five years, we have a robust conversation about where we feel the customers want us to be and where the next turning point for us is,” Pritchard says. “If you ask any OEM what they learned during the pandemic – the importance of strategic business relationships is always at the top of the agenda. We want to be part of our customers’ strategy and understand where they want us to be.”

In attaining this, Philtronics Ltd is assisted by its sister company, Philtronics Solutions, the business’s development arm.

“We get clients approaching us with anything from a concept to a developed prototype, and we can roadmap that and scale it while adding value along that pathway.”

It is exciting work, but for Pritchard, it raises a question.

“Why do we have so much innovation in this country, but manufacturing is perceived as not cost-effective?” he asks. “Whatever you have, we can build it cost-effectively in Wales, in the UK. We need the support to recognise that.”