Established in 2010, Miro Forestry has developed into a progressive and fast-growing supplier of plywood, edge-glued panels, CCA-treated poles, and related forest products to clients in West Africa and around the world, using its own raw material from its own, sustainably managed tree plantations. Over the last few years, Miro has established more new forest areas, on previously degraded land, than any other company on the African continent.

“We are a vertically integrated plywood manufacturing company, planting, growing and harvesting trees in order to manufacture sustainable plywood and other timber products. We therefore have total control over our supply chain from seed to tree and then from log to finished timber product,” says Andrew Collins, the company CEO.

Expanded operation

Expanded operation

We spoke to him in 2020, just at the onset of the global pandemic, when the company was ready to build up its industrial capacities, having successfully planted and developed the plantation for over 10 years. The aim then, as it is now, was to produce a strong and steady flow of wood to be converted into higher value-added products such as plywood and poles for customers around the world.

Over those three years, the company has made impressive progress. In 2021, its 30,000m3 per annum output plywood factory in Ghana was commissioned, followed by a 100,000 pole per annum CCA treatment plant commissioned in Sierra Leone.

In 2022, the company began the construction of a 60,000m3 per annum output plywood factory in Sierra Leone to be commissioned in December this year and has expanded its Ghana plywood factory also to 60,000m3 output. Staff numbers have risen to over 3,000, to be increased further when the Sierra Leone plant starts operation.

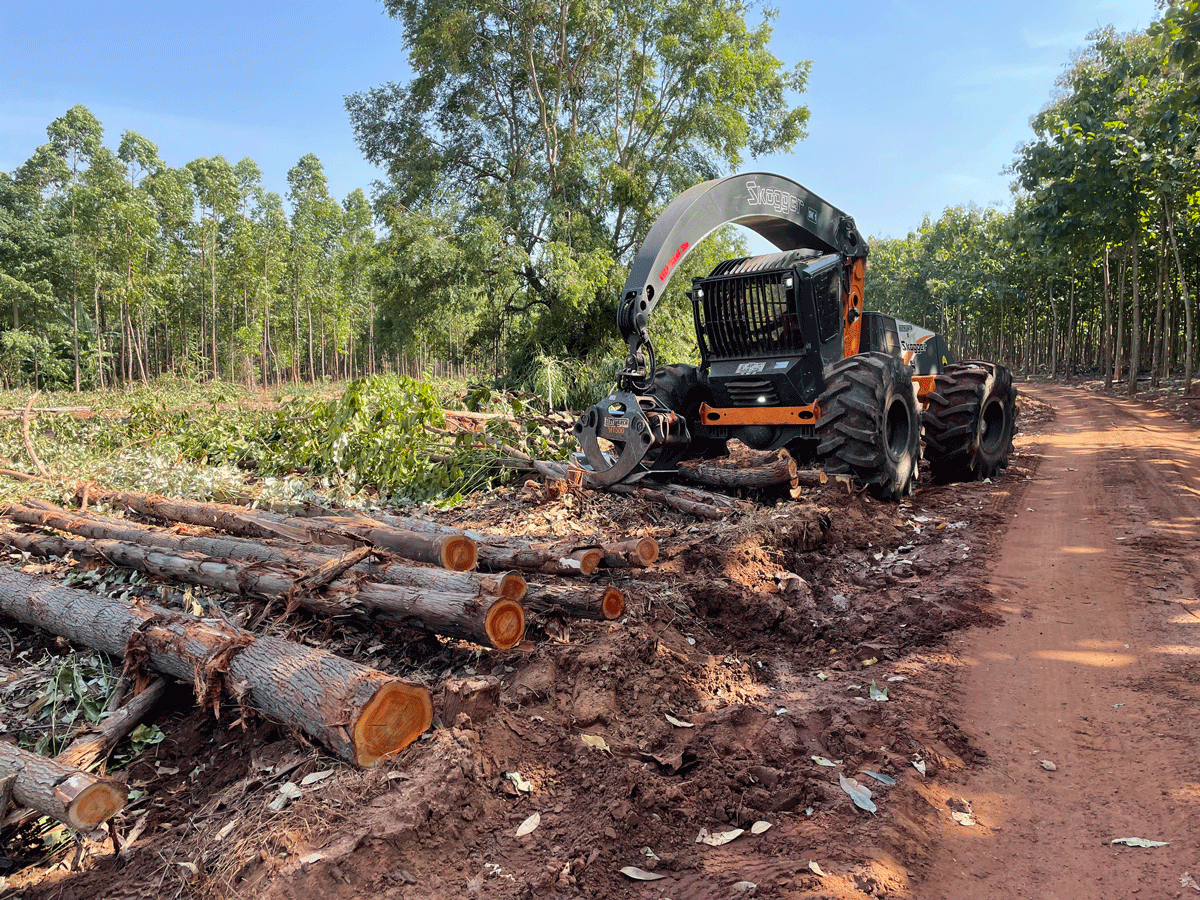

Collins affirms that the plantations remain the core of Miro Forestry. “We continue to maintain our sustainable plantations of 20,000 hectares across Ghana and Sierra Leone. The plantations are now mature, so we are harvesting and replanting, with a focus on having factories available to process the resultant wood-flows into finished timber products. In both countries, these factories are located centrally to our plantations, so our logistics costs are highly competitive while securing a low environmental footprint.”

Vertical sustainability

He points out that the principles of sustainability are applied not just to the plantation but also to the plywood production. “We have biomass boilers utilising our waste wood, we have solar panels on the roof of the factory. For the next factory that we are developing now, we are finalising plans for installing a biomass combined heat and power plant. The fact that our processing plants are close to the timber source means burning less fuel transporting the logs to the mills.”

As a major employer in Ghana and Sierra Leone, the company aims to have a significant economic impact in the areas in which it operates through employment, community development and local procurement of supplies and infrastructure. Miro’s community development strategy includes education, access to clean water and alternative livelihood programmes but Collins affirms that Miro’s mission for community development is to help communities help themselves through the economic independence the company brings, by providing employment in the local area.

“The main benefit is providing liquidity. Previously, in these rural areas where we operate, there was very little formal employment, with barter trade in place and little cash availability. As a significant employer, we have aided the development of a cash-based society to emerge, leading to a greater array of jobs and prosperity, transforming the local environment.”

“We have also been creating roads in the plantation in order to manage the forests, and those roads are often used by communities. This means better access to the market as well as access to medical care, which was limited in the past. In this context, it is not only the individual CSR projects that we implement but the overall economic impact on the region that is most appreciated.”

Long-term vision

Long-term vision

Miro Forestry has by now supplied 30,000m3 of quality plywood to high-profile customers based in Europe, the UK, the United States, the Middle East, as well as West and North Africa. “Our product is Forestry Stewardship Council (FSC) certified, we meet all ISO standards, and have all the sustainability certifications, which is a very attractive proposition as there is a shortage of sustainable timber on the market. We also promote economic and social development in the countries in which we operate, and customers increasingly like the story behind our production.”

Despite its growth, the company has not been spared the effects of rising inflation, resulting in a large decrease in construction activities on a global scale, and decreased demand for all building material products. “We are faced with quite depressed market conditions at the moment, compared to the buoyant market which occurred during the pandemic. Nevertheless, we are continuing to win market share.”

Collins affirms that the recent expansion has been planned all along, irrespective of market fluctuations. “We can’t respond quickly to market ups and downs because it takes seven years to grow a tree. Even if the markets decreased, we would still be expanding. We build the forests on the long-term demand trends, and therefore regardless of how timber markets fluctuate over short-term horizons.”

As such, further industrial plywood manufacturing expansion is planned to match the scale of the forests developed by the company. As a result, Miro will more than quadruple its capacity over the next decade. This growth will be in line with Miro’s plans to safeguard areas of natural and indigenous forest, in order to protect flora and fauna and promote biodiversity. This concept of sustainable forest management ensures a corporate contribution to the country, its people, the environment, and the future.