MTorres, established in 1975 in northern Spain, has grown into a widely recognised group that designs, builds, and installs automation equipment used in factories around the world. The company’s clients primarily operate in two sectors: aerospace and paper processing.

MTorres’s aerospace product range covers many of the processes that are needed to fabricate aircraft parts, such as fuselage or wing panels, and the equipment and tooling needed to assemble these parts into a final product, the plane.

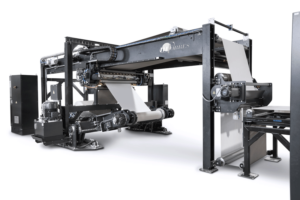

The company’s paper-processing equipment can be found in many production lines that automatically print, laminate, fold or cut paper to make packaging products like corrugated board or liquid aseptic packaging, i.e., paper-based products used in everyday life.

The group, which today employs over 400 people, remains a family business. Now in the hands of the second generation of the Torres family, its headquarters continue to be near Pamplona in northern Spain with production and service centres located in Murcia in southern Spain as well as in Germany, the US and Brazil.

Driven by innovation

Driven by innovation

“Our core expertise lies in high-tech automation equipment deployed in production processes where speed and quality of the solutions are the name of the game,” says company CEO Juan Albeniz. “All of our machines are made to order, supplied primarily to global companies such as Airbus, Boeing and Tetra-Pak, to name just a few among many, who need state-of-the-art solutions incorporating the latest available technology. Sometimes they even work with us in the early stages on technology that is not yet available.”

Albeniz affirms that MTorres is a business that is innovation driven, which is one of its key competitive advantages. “Innovation has been in our DNA from the very beginning, when Manuel Torres, who sadly passed away in 2020, founded the company nearly fifty years ago. Manuel was a phenomenal character: inventor, entrepreneur, incredibly curious, relentless and convinced that he could help solve the industry’s toughest problems, which – in many cases – he did.” That ethos is still present in the company.

Human capital is another differentiator. “Engineering and design form a substantial part of the business and it is our people that make the difference. I am absolutely convinced that we have the best team in the industry,” he affirms.

Customers’ Choice

“We are also highly customer-focused. In our two industries, customers collaborate with suppliers in a way that’s way beyond transactional: they know they can count on us not only in terms of project execution but also in product development, taking on new technological challenges.”

Similar approach is applied to MTorres’s own supply chain, and solid partnerships with innovative, reliable companies, such as, for example, FISCHER AG Präzisionsspindeln, the Swiss innovator of rotation technology, are the basis of MTorres’s solid market position.

Juan Albeniz points out that here are many achievements made over the years that the company can be proud of, including many industry-first products and systems and over 180 industrial patents. But ultimately, the greatest achievement is the overwhelming confidence of customers, which has made MTorres number one in most of its markets.

“When you walk around major factories producing or assembling aeroplane structural parts, which are arguably some of the most sophisticated and demanding factories in any sector of industry, you will see not one but many MTorres logos on the machines. The positive customer feedback translates into an extremely high rate of repeat,” he says. “There is no better achievement than the trust of your customers.”

Enhancing manufacturing processes

Enhancing manufacturing processes

Reflecting on current market tends, he affirms that sustainability is the biggest driver and game changer, affecting both of the company’s sectors profoundly, as well as MTorres’s own operation where substantial investment has been made, for example, in energy savings.

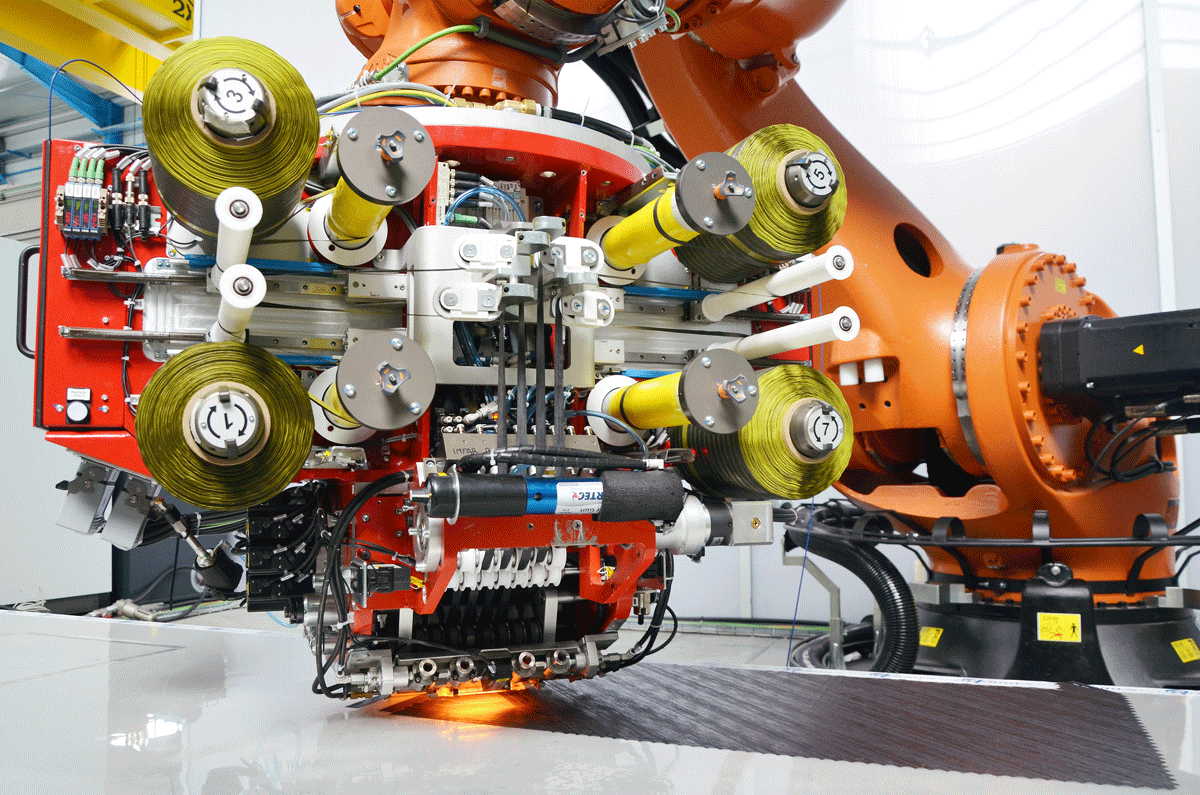

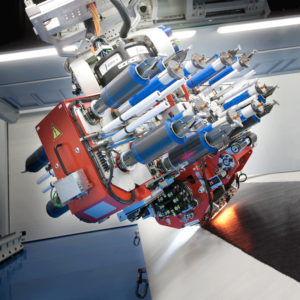

But the company’s innovative thinking has a wider reach. “In the paper industry we help our customers transition from plastics-based or plastics-heavy solutions to paper-based solutions. And in aerospace, the quest for more sustainable solutions, be it higher fuel-efficiency, alternative fuels like hydrogen, all-electric aircraft, is arguably THE most important innovation driver. Here again, we can offer valuable improvements, such as equipment to fabricate carbon-fibre composite parts.”

Significant success has already been achieved. Last year, MTorres won the JEC Composites Innovation Awards within the Innovative Infusion Airframe Manufacturing System (IIAMS) Clean Sky project that simplifies the manufacturing process of composite components and has been developed in conjunction with Airbus.

The project opens up a new future for composite materials processes adding several benefits from process simplification and flexibility to cost, energy and weight savings in the final parts, together with the creation of fast implementation and deep optimization of all the stages, demonstrating how the manufacturing processes of the future will be shaped.

Soaring to new heights

Operating in a cyclic environment, MTorres experienced several difficult years but survived in a robust shape, ready to soar with reviving demand. Juan Albeniz says: “There have been two factors that helped us offset the hard times: first, the paper equipment sector remained resilient and second, importantly, we were able to retain core talent.”

“Now the challenge will be to have the capability to meet the skyrocketing demand. In sectors that are historically cyclic, growth and investment need to be managed smartly and carefully, to sustain flexibility. We now focus on investing in talent acquisition as well as R&D to further improve our products, to make them faster, better, more efficient.”

In concluding, he affirms that the outlook for the next 12 to 18 months is highly positive. “We remain extremely committed to our customers and will strive to maintain our unyielding standards of quality and delivery, the factors that have helped MTorres achieve its string position in global markets.”