Often you can judge a business by its customers. If it is a top-of-the-line business, the odds are you will recognise the names of the companies it sells to. With Intrepid Powerboats, you will recognise the names of the people it sells to. Names like Enrique Iglesias, Larry Silverstein, and Gloria Estefan. These are all people who have taken to the waves in an Intrepid Powerboat.

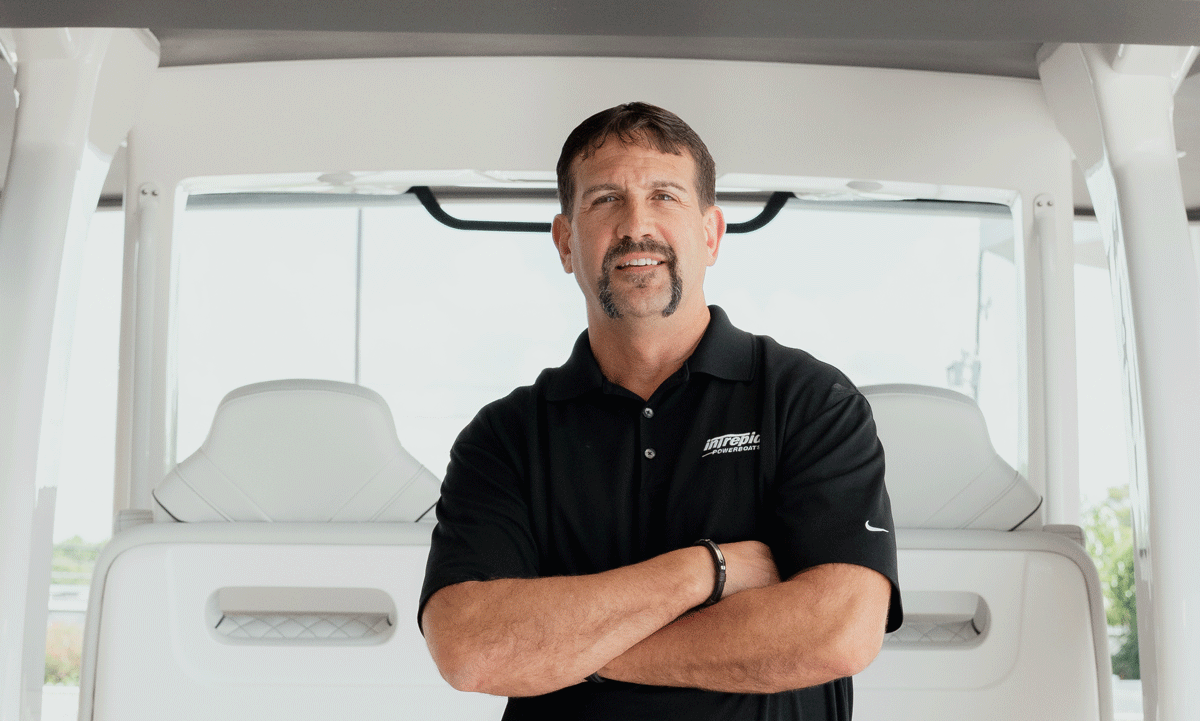

“Our clientele wants the best and expects the best,” says Ken Clinton, Intrepid’s President.

Intrepid’s range includes 12 different models of smaller boat that are continually being upgraded, refreshed, and given new configurations, but that is only the beginning of the customisation options that Intrepid can provide.

“If you come in and ask for a 41 Valour, we sit down and pick everything with you from the hull side paint colour to the pillows,” Clinton explains. “It’s not like going to a parking lot where they offer you a choice between the red one or the blue one.”

Intrepid is known for boats in the 30-to-51-foot range, although when we speak to Clinton the firm is in the middle of designing its new 64-foot flagship. To ensure Intrepid keeps offering the choice and quality that its customers expect, Intrepid is constantly innovating, but it is innovation with a long history behind it.

A History of the New

Intrepid came onto the market in 1983 and quickly built a reputation for innovation.

“We have created more innovations that the industry has followed than any other manufacturer that I know,” Clinton says.

As an example, Clinton points to the dive door you will find on almost all boats now. Intrepid were the first to introduce that in 1994. Intrepid were the first boat makers to introduce a 35-inch shaft outboard, manufacturing it themselves after Yamaha said there was no market for it. Yamaha has since introduced 35-inch shaft outboards.

The list goes on. The first boat maker to put a gyro in an outboard boat? Intrepid. The first to have a bow thruster? The first with a head compartment inside the centre console? The first to do forward seating with actuating electric backrests? At this point, there are no prizes for guessing the answer.

Intrepid were also the first to paint their engines to match the boat – a controversial move that received pushback from engine manufacturers.

“Every engine manufacturer was telling me I couldn’t do that,” Clinton remembers. “Funnily enough they all paint them white now too.”

The trend continues, as today Intrepid are the only company to make boats with a hi-low actuating helm.

“But someone will copy that soon,” Clinton assures us.

This latest innovation is borne of a desire to bring ergonomics into boat building.

“That is one thing we’re not very good at in the marine industry,” Clinton points out. “So, I work very hard at that. I came up with the electric actuating system so that the push of a button raises the whole section four inches for the helmsman if they are shorter.”

The Handmade Touch

But this is not innovation for its own sake. Intrepid sells itself on the quality of its customer service as much as the range of new options it can provide, and to Clinton, these are two sides of the same coin.

“We are leading the industry, but we are also leading it in terms of customer service,” Clinton says. “If you go online and ask around, people will tell you there is nobody better in the industry. We answer the phone on Christmas day. We know it is important we take care of our customers and provide the quality we are known for. We are the Rolls Royce of the marine industry.”

These priorities – innovation, quality, and customer service are baked into Intrepid’s origins. When Intrepid was new on the market, it needed to find a niche. It quickly found one very few were competing for.

“When you drag a boat behind a mega yacht, it is the most punishing ride a boat can have,” says Clinton. “Most manufacturers try it, and their boat gets destroyed. They cannot cover the warranty. So, as a small company, we said ‘We’ll take any market share we can get’.”

Intrepid’s solution was simple – overbuild everything until it could take all the punishment the waves could throw at it.

“We have that same philosophy today,” Clinton says.

Intrepid hand glasses every stringer and bulkhead. The boats include fibreglass parts in shapes designed for robustness and function over ease of manufacture.

“The tricky part about that is you have to pull the parts out of the mould by hand,” Clinton says. “We pull the mould itself apart in pieces, like the shell on a hardboiled egg to get at the part inside.”

The result is a boat made up of magnificently shaped parts, so why do all boatbuilders not use these techniques?

The result is a boat made up of magnificently shaped parts, so why do all boatbuilders not use these techniques?

“Because it’s so labour-intensive they don’t want to take that hit to their margins,” Clinton tells us. “We are willing to sacrifice margin for quality.”

For Clinton, this is an informed choice. He has been with Intrepid for 33 years, and he started with the company as a hands-on craftsperson. Two months after that, he was the lead on station one, overseeing the prepping of the hulls, the decks, the fuel tanks, and plumbing. He moved up the ranks through line supervisor, plant manager, VP of manufacturing, then COO, until he became president of the company in 2009.

But he has not forgotten his days on the line and considers it a key competitive advantage.

“I am one of few presidents who is a hands-on boat builder,” Clinton says. “I don’t ask employees to do anything I have not done, and in design sessions with customers I know exactly what we can and cannot do.”

These days, however, the challenge is finding people who are willing to do the work that Clinton started out doing.

“A lot of people do not want to work with their hands anymore, so seeking out the people who do is a huge challenge,” Clinton says. “That is what we want- true craftspeople, not just staff on an assembly line. We are enticing people to build something they can take pride in.”

Clinton is continuing to build something he can take pride in, with Intrepid’s new owners, MarineMax, supporting the creation of a new yacht division for Intrepid. Plans are in place for a bigger facility to build larger boats.

“Our customer base has grown. We have gone from 47-foot sports boats to 51-foot or 64-feet. Once they grow outside of our overall length, customers are forced to go to a different brand, and they quickly find they miss our level of quality,” Clinton says. “So, there is pressure to build bigger boats with the customer.”

Our interview ends there. Clinton is getting ready to fly out the next day to the facility where they are designing Intrepid’s new 51-foot Panacea model.

“I’m going to spend the week with my team just working on the design,” Clinton says. “That model is a major part of the future. That, and to continue innovating.”