Torque Africa Exploration was founded in 2014 by Nardus Bezuidenhout, who brought his 22 years of experience in the onshore drilling industry to the firm. Seeing the rapidly growing demand for turnkey drilling solutions at home and abroad. It was a demand Bezuidenhout positioned his company to meet. As the company expanded to become the Torque Africa Group, its offering would also expand to include RC exploration drilling, air core drilling, percussion drilling, and input grade control drilling.

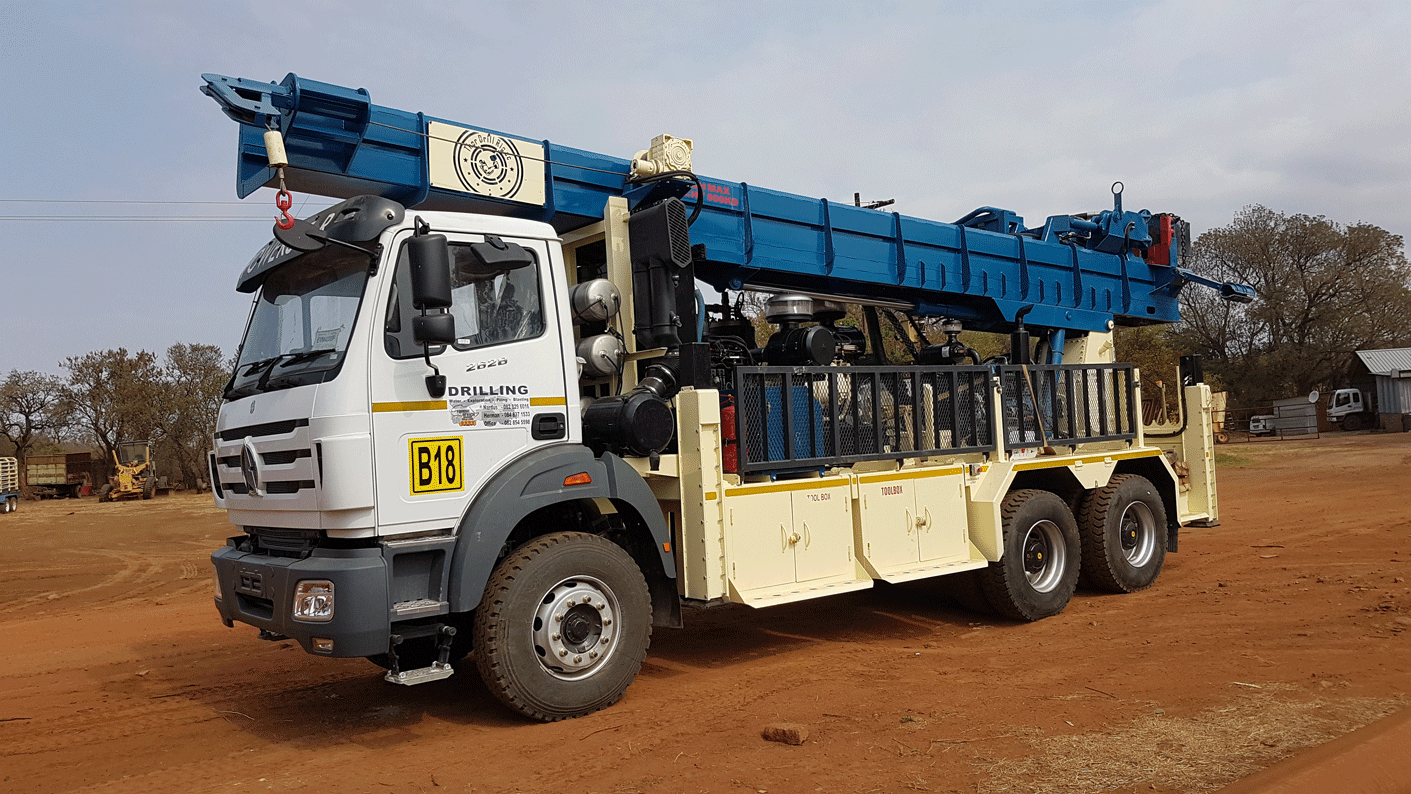

“Torque Africa is an onshore drilling company that does large diameter and deep wells in the exploration and gas industry,” Bezuidenhout tells us today. “The company, which is under my sole ownership, runs a fleet of over 30 drilling machines alongside a range of additional equipment.”

Torque Africa runs top-performing, modern drilling rigs as part of its fleet of 200 licensed vehicles, run and maintained by a team of over 200 employees. This wealth of resources means that Torque Africa Group is positioned to deliver the very highest standards and quality in the drilling industry.

“We are working in Southern Africa including South Africa, Namibia, Eswatini, Zimbabwe, Mozambique, Botswana and elsewhere, such as Central Asia, Pakistan, Algeria, and West African countries as well,” Bezuidenhout explains.

“We are working in Southern Africa including South Africa, Namibia, Eswatini, Zimbabwe, Mozambique, Botswana and elsewhere, such as Central Asia, Pakistan, Algeria, and West African countries as well,” Bezuidenhout explains.

But while the company has a growing fleet of vehicles and equipment and an expanding international footprint, it has maintained the bespoke approach, strong interpersonal relationships and innovative approach that are the key selling point of a smaller business.

“We are not yet a large corporate company, so you get that one-on-one customer service,” Bezuidenhout says. “We are not scared to do new things, and we can think outside of the box. We are entrepreneurs. This is how we have achieved a few world records. We hold the record for the deepest RC well in the world.”

This record, which involved drilling an RC hole down to 1019 metres in Amam, in the Northern Cape of South Africa, was established in 2020. That depth was reached in the astonishingly short period of only nine days of continuous drilling. But it was not simply a question of drilling downwards. It was an intricate and complex project that required meticulous planning, leveraging years of experience and detailed knowledge of the ground conditions in the area. Bezuidenhout has reason to be proud of the achievement, having led the project personally. This is a hands-on approach that can be seen across all of Torque Africa’s projects.

The Problem of Power

Another thing that all of Torque Africa’s projects have in common is that they all require power, and in South Africa that can sometimes be a major obstacle. “We face challenges such as load shedding in South Africa, and that can have a knock-on effect on the supply of materials because suppliers don’t have electricity to manufacture,” Bezuidenhout says.

One of the solutions Torque Africa Group is deploying is to draw materials from further afield, by importing from abroad. The company is also carefully managing stock. “We make sure we have on-the-shelf equipment to accommodate any shortfalls,” Bezuidenhout says.

However, when it comes to power supplies, the business has adopted its own innovative solutions. “We have evolved our own solar power systems to create energy for our workshops,” Bezuidenhout points out.

The Right People in the Right Place

The Right People in the Right Place

Of course, as Torque Africa Group expands its reach and enters new territories it faces new challenges, particularly from a regulatory point of view.

“Health and safety are not standardised around the world, so every time we enter a new market we must add new safety standards,” Bezuidenhout says. “It changes a lot from place to place.”

To keep up with the changing regulatory environment, Bezuidenhout employs specialists to ensure its work is in accordance with any standards its clients might have.

“We employ safety managers that act as a key contact point between ourselves and the customer to accommodate all the health and safety standards we might encounter,” explains Bezuidenhout. “It is about changing your mindset, looking for better ways to address each new situation.”

This is just one example of the importance Torque Africa places on its people. When we speak with Bezuidenhout the company employs 200 members of staff around the world, and they are all vital to the company’s success.

“Because we are working all over the world, primarily in the southern part of Africa, we require different kinds of people across different categories,” he tells us. “We invest in people. We train them, we offer people courses to upgrade their skills. These people are our most important asset. That is what makes us successful- the people that work for us.”

To make the most of those assets, Torque Africa Group takes a personal interest in each of its employees.

“We know our employees’ personal problems, their living standards, and we have a good relationship with them,” Bezuidenhout tells us.

Bezuidenhout believes that the company’s future will depend on long-term relationships with Torque Africa’s staff, its supply chain, and its customers.

“Human resources wise, we try to maintain a good term relationship with the people that work for us,” Bezuidenhout insists. “Our rule-of-thumb is that we will help any customer to build a programme, joining up with them as a partner in the drilling industry and working together for the long-term benefit of both parties. We want to be on the customers’ books as a partner of choice. That is why we make a commitment not to over-charge, to develop long-term relationships across the industry, especially with the green field exploration phase.”

Torque Africa’s approach is not on a project-by-project basis but with the goal of building relationships for four-to-five years into the future, or more. And that future is bright.

“Gas energy in Africa is booming because of the energy shortfall, so there is a focus on exploration right now. We have made a considerable investment in R&D within the onshore gas drilling sector. It allows us to design and implement a hole design and drilling technique uniquely suited for the Southern African conditions and requirements to accommodate the gas ‘gold rush’,” Bezuidenhout says. “We have plans up to 2026 to build the company, and then we are going to restructure, join up with other partners and build ourselves up. We are drawing a bigger picture for the customer base.”