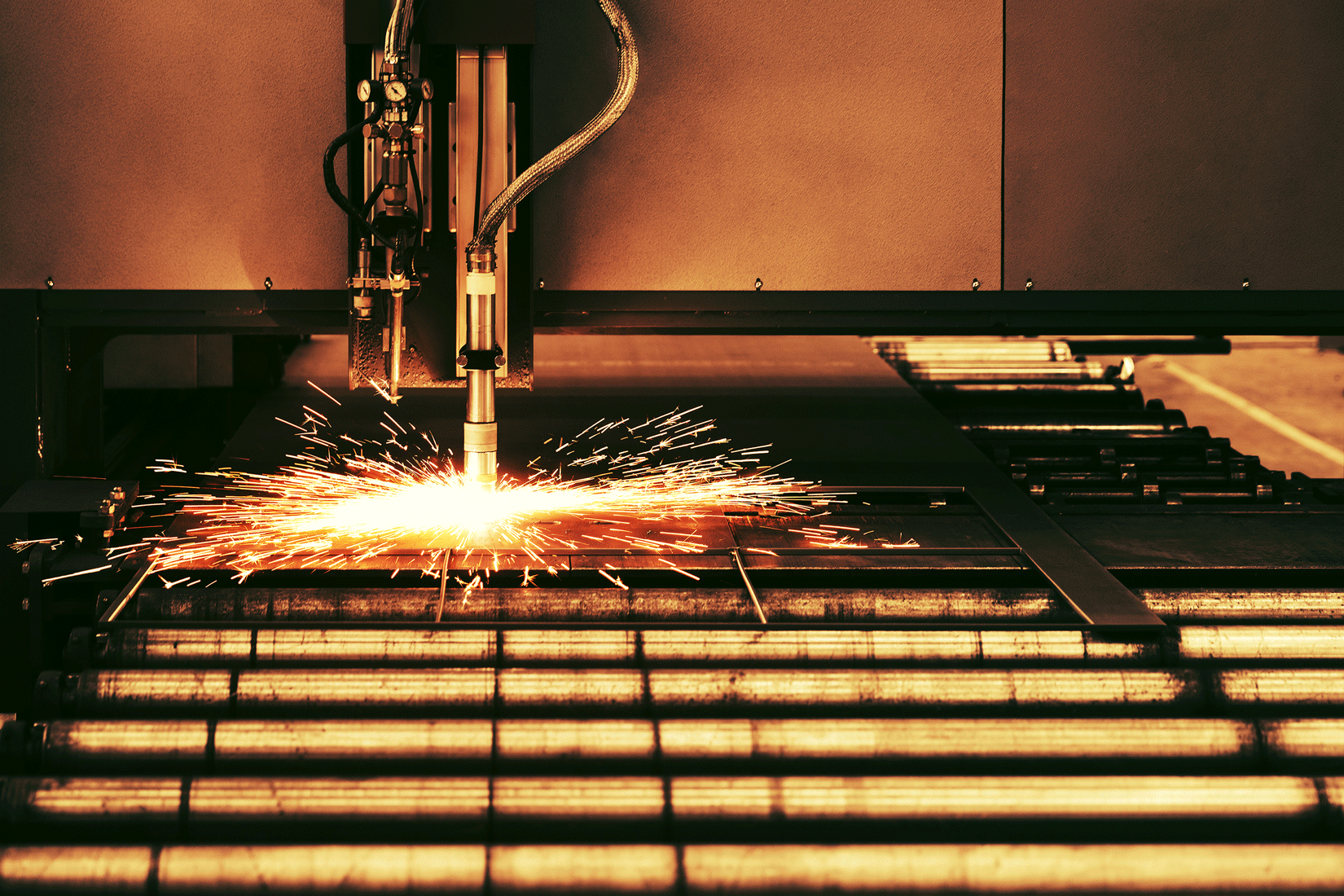

Aurora Profiles is a steel profiler equipped with both Oxy-Gas and High-Definition plasma cutting machines for cutting profiles from mild steel plates. Primarily serving the structural steel market, Aurora works with fabricators and construction firms that erect stadiums and office buildings around the UK.

“Customers supply us with detailed drawings or .nc files that specify thickness and grade, then we’ll cut those shapes out of the appropriate plate, and the customer will weld them together,” says Russell Mercer, Aurora’s General Manager. “We will do anything you need to one piece of steel, drilling, machining, countersinking etc. but stop short of welding them together.”

The company is built on two key principles, quality, and reliability. The construction industry is defined by a critical need to hit deadlines, but typically not a huge capacity for storing stock. That means Aurora’s customers depend on it living up to those values.

“Our customers require delivery that happens when we say it’s going to happen,” Mercer says. “With these huge projects, if they don’t hit their stage build targets there are massive financial repercussions. Our reputation is built on the fact we deliver reliability. That is what we pride ourselves on.”

It means Aurora’s customers can reliably plan their own production schedules while operating on a just-in-time delivery basis.

A New Group

A New Group

These are the values that have been leading Aurora since the company was founded in 1996 by a band of former employees from British Steel when an opportunity arose for them to leave the company and start their own business. They continued as the main shareholders of the business until last year when they sold the business to investor Daniel Beaumont. Beaumont bought Aurora as part of a project to build a Group of companies, including Paragon Toolmaking and Fairgrieve Composites.

“He was looking to get the combined group turnover to approximately £10 million per annum,” Mercer tells us. “The other companies had a combined turnover of £6 million, so our £4 million turnover took him to his target.”

But while Beaumont has taken over ownership of the company, Aurora’s management team is still in place doing what they do best.

“We have not seen too much change,” Mercer says. “I’ve been here for 14 years as the Commercial Manager and when the outgoing Managing Director left, I stepped up into the General Managers role and began recruiting someone to fill my shoes as Commercial Manager. Daniel was very keen to ensure we had stability and the majority of the management team stayed in place after the takeover happened.”

While the change in ownership has led to some consolidation, it always helps if every company in a Group uses the same accountant, the day-to-day running of Aurora has not changed, and Beaumont has been happy to let the existing management team run things as they see fit.

And their expertise is needed as the market is going through some challenging times.

Remaining Flexible

Over the last year, the entire steel industry has been rocked by wildly fluctuating steel prices and availability. As Mercer points out, “Our main UK mill supplier is Ukrainian-owned and the majority of its raw steel slab came from Mariupol, which the Ukrainian army was using as a fortified refuge. So that mill was not only unable to supply the UK but the rest of the world. It had a massive effect on steel prices, doubling them in a matter of weeks.”

Since then, the market has calmed down to what Mercer considers normal levels, but the fluctuations left a huge gap in everyone’s capacity. Fortunately, Aurora’s careful stock management helped it to navigate the crisis.

“As a business, we manage our stock quite closely turning it over 12 to 15 times a year,” Mercer explains. “In a rising market that’s good, but it also means that when the price turns, we are not stuck with high-value stock that is too expensive.”

But while Aurora Profiles has a high turnover of stock, its staff turnover is quite the opposite. As Mercer points out when the company hired his replacement when he stepped into the General Manager role, that was the company’s first new hire to the management team in 11 years. Even when hiring is necessary, it typically uses personal relationships and word of mouth to find the right candidate.

“We are in an industry where everyone knows everyone else,” Mercer says. “You know who your competitors are, who is good. When we hire it tends to be people we know from within the industry.”

Aurora Profiles can afford to hire so little precisely because it hires known quantities and values the people it has.

Aurora Profiles can afford to hire so little precisely because it hires known quantities and values the people it has.

“We know the people we recruited in advance of them working for us, and we are fair in terms of the wages that we pay. We benchmark against other companies in our sector,” Mercer says. “We look after our guys.”

Consolidation for the Future

With the company under new ownership, this is a time of consolidation for Aurora Profiles.

“Daniel [Beaumont] wanted the smoothest transition possible,” Mercer points out. “Six months into our new ownership he pretty much leaves us to do what we have always done. We will give him our KPIs on a weekly basis and he can see how we’re performing.”

As for where the company might go next, Mercer sees possibilities ahead, but ultimately it is a decision for Beaumont.

“The site we are on the at moment means it would be difficult to expand our premises. Around us, we have cinemas and bowling alleys and fast food, so we stick out as an engineering company,” Mercer points out. “We do not have space for additional machines, and we already run a night shift. It would be a big decision and a big move to new premises, but that might be necessary to take us to another level.”

However, there is one thing Mercer is certain of, and that is that there is plenty of business out there.

“The structural steel market in recent years has been strong. Sports stadiums have been a good source of business for us. We have also supplied steel profiles into some of the iconic high rises in central London such as the ‘Shard’ ‘walkie-talkie’, and the ‘cheese grater’. Those are the kind of projects we are in the supply chain for.”