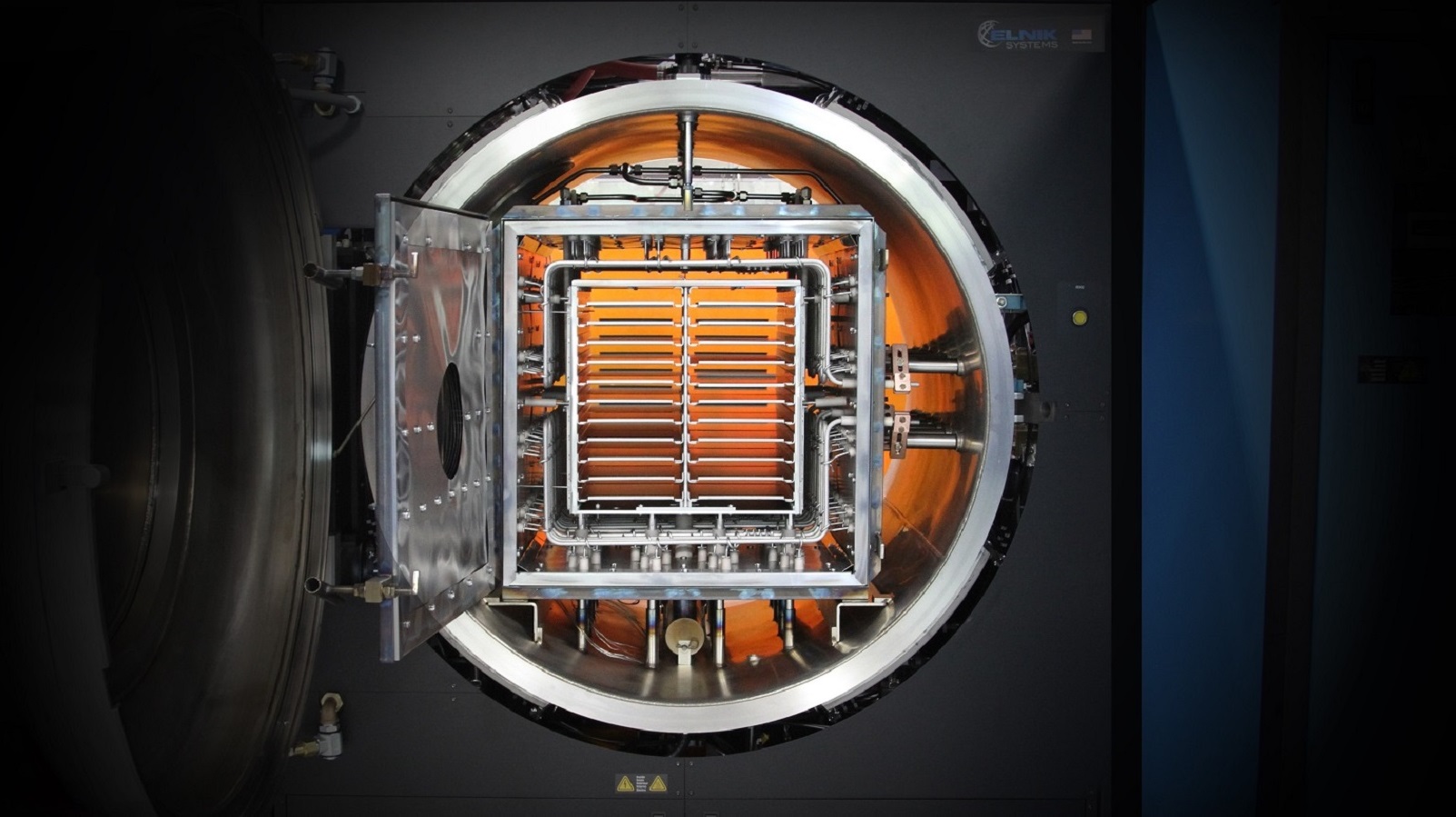

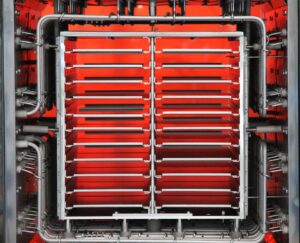

Elnik Systems is a manufacturing company that builds equipment used to de-bind and sinter metal powder parts. This furnace technology is used in metal part-making industries that utilise injection moulding or 3D printing technologies to form parts. Once the parts are formed, Elnik’s furnace technology is designed to remove the polymer binder material and fuse the metal powder together to achieve a high density, near net shape or net shape part.

“We support our customers not just with our service team in the US and Germany, but we also do a lot of processing engineering and education as well. We have a sister business named DSH Technologies that supports customers with process challenges,” explains Stefan Joens, President of Elnik Systems.

What makes Elnik’s equipment stand out is that it is the most flexible currently in use that meets the industry’s needs, combined with the wealth of knowledge and education its experts can provide around the process.

“We have people who have been involved in actually making power metal parts on our team. We don’t just sell equipment, we provide full support including part design, processes knowledge and troubleshooting,” Joens emphasises. “Elnik makes equipment for this market but our sister business, DSH Technologies, carries out a lot of that process engineering support for making metal parts. If a metal part doesn’t meet the chemical or mechanical properties necessary, we can figure out why.”

To do that requires a special breed of homegrown knowledge.

“The world of available employees is ever-changing and in today’s situation, it is not as easy to find people with all the skillsets needed to meet the job requirements,” Joens points out. “Instead, our approach is to find new team members with the best personal skills and potential to meet our cultural environment. From here, so long as the person applying for the role has enough of the basic skillsets, we can develop them into amazing team member through onsite training and systems.

There are few industries that Elnik has not already served, as Joens says, “We are fortunate enough to have the opportunity to work together with companies supporting the aerospace, medical, fashion, and defence sectors, as well as providing general tools and components and working with super niche industries that cannot be spoken about.”

A New Home

With manufacturing sectors growing and countries onshoring existing outsourced technologies, it is not surprising the company has grown rapidly.

We have seen phenomenal growth. The company has almost doubled in size in three years,” Joens points out.

So phenomenal is that growth that Elnik has begun to outgrow the facility it shares with its sister company, DSH. This is why this summer Elnik is going to be moving to a brand-new facility in Charlotte, North Carolina.

“We needed to locate our business into a larger facility, all under one roof so that we can continue to control our manufacturing process and build our state-of-the-art equipment,” Joens says. “New facilities within NJ are best located over 45 minutes south of our current location, which would require some people to relocate. The potential for some team members to relocate sparked the question, would people consider moving further away or out of state?”

This question led Joens to explore a broader area up and down the east coast of the US, eventually finding the Charlotte region of North Carolina to be extremely attractive.

“I used Charlotte as a hub when exploring the southern states. Every time I had the chance to explore this specific area, it felt more and more like a home for us,” Joens recalls. “There are many similarities in how the towns are laid out and the number of trees. Let alone the access to mountains, beaches, major cities and amazing universities”.

A combination of high taxes, operating costs and regulatory burdens in New Jersey also made North Carolina an appealing prospect for Elnik.

“There are a lot of regulatory challenges in New Jersey,” Joens says. “It takes two months to do in Charlotte what takes six-to-twelve months to do here in NJ.”

At the same time, New Jersey consistently ranks near the top of lists for states with the largest outgoing population, and Joens was keen to move somewhere that could grow alongside his business.

“For more than 20 years we have focused on de-binding and sintering. Where other furnace companies pursued more diverse markets, we focused on this one technology,” Joens says. “As 3D printing grows, it becomes a more viable way to make metal parts that could not have been made otherwise. The use cases will grow and Elnik’s future is to continue to support and innovate for that industry.”

What the Industry Needs to be Sold

Joens has a clear enthusiasm for the possibilities 3D printing can offer small businesses to compete with their larger counterparts and manage the CAPEX requirements.

“We care more about getting people involved and educated about the possibilities of this technology than we do about selling equipment,” Joens says.

But while the possibilities for the technology are exciting, Joens also believes it is not living up to its potential. He believes it is being miss-sold.

“For the last six months, I have been thinking about the metal 3D printing industry. Its growth has been challenged. Covid is certainly part of that, but I think the biggest reason is a lot of companies, even those selling 3D printers, are going after other industries saying, ‘We will replace your manufacturing technologies with our technology,’” Joens argues. “While there certainly may be a few wins a company can make taking over existing technology, I think that’s the wrong way to approach 3D printing. The message and education about this technology needs to shift away from ‘I can use my technology to do what you do’ to ‘I can use my technology to do what you cannot do.’”

Joens believes that a mindset shift from a design and engineering perspective is essential for the technology’s future.

As he says, “The training and knowledge-sharing need to be about using 3D printing to make something better than could ever be made with other processes. An example is that metal injection moulding has been around for over 40 years. In many cases, it is currently providing parts at the lowest possible cost. It is going to be difficult to just replace that manufacturing technology. Part makers need to change the approach and start asking their customers what challenges they currently have with any parts they make or buy, then utilise their experience and knowledge of 3D printing to support overcoming some of those challenges and headaches. Have your customers help you with how to use the technology from an application base. Too many companies are trying to determine what part to make for an industry when they should just ask the industry what they need.”