With a strong engineering background and a firm global footing, Sweden-headquartered Nefab provides complete packaging solutions, logistics services, and optimisation programmes that save financial and environmental resources in its customers’ supply chains.

Established over 70 years ago, the company has developed from a manufacturer of heat-resistant bread boxes into a leading global player employing over 4,200 people in 70 facilities and offices in more than 30 countries, serving companies in industries such as telecoms, datacoms, energy, automotive, healthcare, aerospace, and lithium batteries.

“Since the company’s foundation in Sweden in 1949, we have been providing customers with sustainable packaging solutions,” said Mr Rui Garrido, Executive Vice President, Industry & Europe.

“Since the company’s foundation in Sweden in 1949, we have been providing customers with sustainable packaging solutions,” said Mr Rui Garrido, Executive Vice President, Industry & Europe.

“Today, we are a world-leading transport packaging solutions company that provides high-quality, engineered packaging and logistic services worldwide.”

He added that due to the strong focus on innovation, the company has introduced over the past years a range of packaging and logistic solutions to support the transformation of modern supply chains to become more sustainable, efficient, and environmentally friendly, helping to reduce cost and carbon footprint. “To give you an example – by 2026, Nefab plans on saving 10 million tonnes of CO2 emissions in customer supply chains.”

One of a Kind

Today, the company has an impressive global footprint. “We have grown in line with customer demand for complete packaging and logistics solutions, which has led us to widen our product and service portfolio,” explained Mr Garrido, adding that this has been achieved through acquisitions – over the last 20 years, Nefab has acquired more than 30 companies.

“As such, the company is able to satisfy local customers’ needs for global partnerships and support. A great idea delivered in one company in one market is good but scaling it globally is better!”

“Another factor that has helped the company to grow is packaging engineering – the development and re-design of packaging solutions that enable cost-efficient transportation, handling and storage. Today we have more than 200 engineers working globally and several testing centres worldwide. This has been critical for securing and sustaining our global leadership position.”

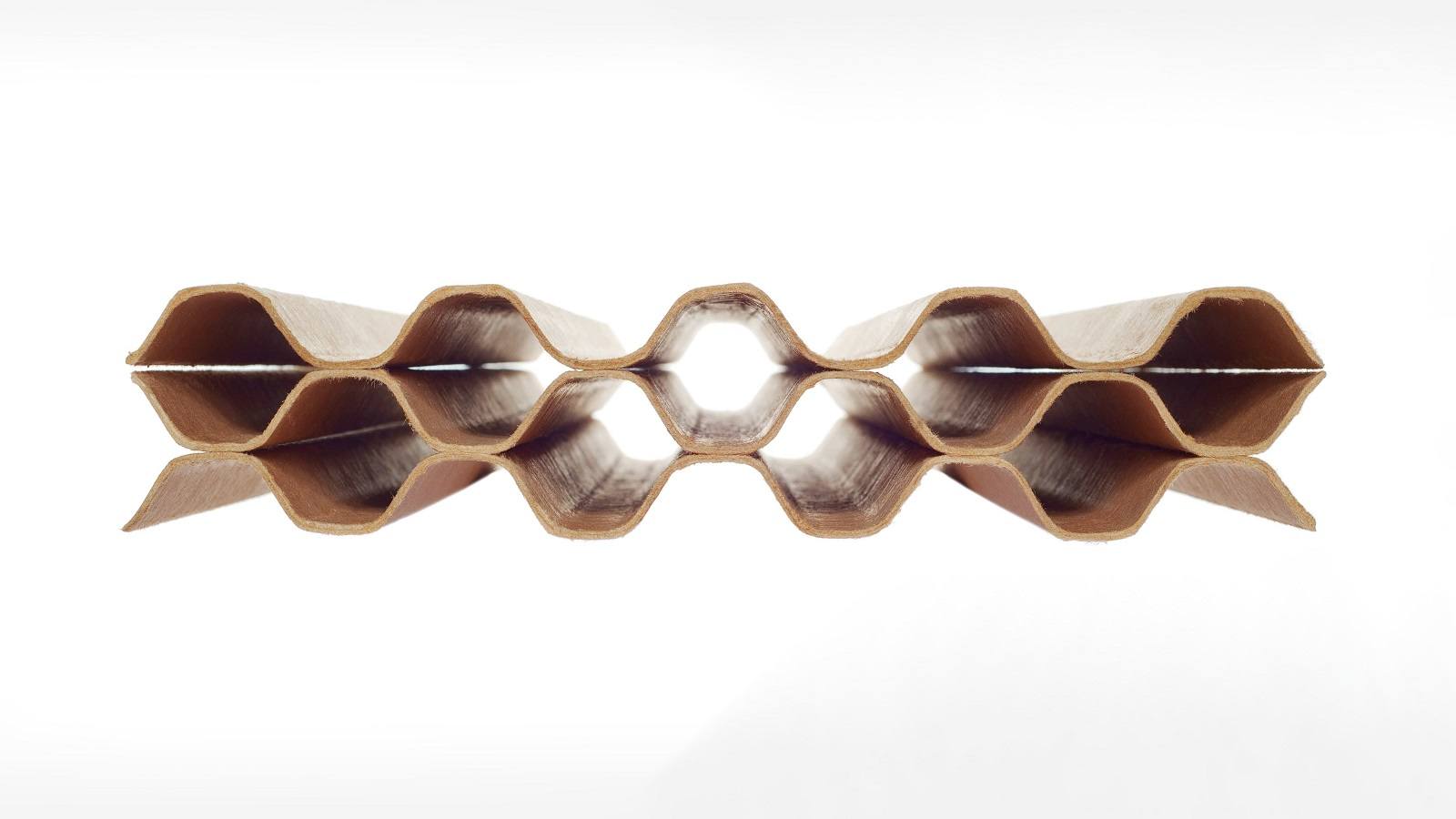

Over the years, the company has introduced many ground-breaking innovations, such as its fibre-based packaging solution for lithium-ion batteries that won the sustainability category of the German 2022 Packaging Awards, Europe’s biggest showcase for packaging achievements.

Another example, showcased at Fachpack 2022 in Nuremberg, is their newly launched range of sustainable plastic packaging, including thermo-formed trays and cushioning applications. Both are made primarily from recycled plastics and 100% recyclable materials and are an efficient alternative both for one-way flows, as well as for return and circular flows.

Thinking Green, Acting Green

Mr Garrido pointed out that considerations for the environment and sustainability have been an integral part of the business for many years, reflected not only in the products and solutions offered but in the whole way the company operates.

Mr Garrido pointed out that considerations for the environment and sustainability have been an integral part of the business for many years, reflected not only in the products and solutions offered but in the whole way the company operates.

“First of all, sustainability is a requirement from our customers – we need to provide them the evidence and help them become more environmentally friendly. Sustainability is also key for the company’s employees, both for retention and development but also for attracting people.”

For its customers, Nefab offers a unique Life Cycle Analysis (LCA) platform called GreenCALC which enables them to clearly visualise their flows and traceability, and to quantify environmental savings.

“The ability to visualise the financial and environmental savings of customer’s decisions, based on packaging solution optimization, is something that we are proud of, and I believe we are the only company today that can provide this.”

Nefab has collected numerous awards in the sustainability arena and has been voted Supplier of the Year with regard to sustainability by many of its global customers.

Group Brand Director Peter Malmqvist remarked that Nefab continues to invest in R&D to develop circular solutions: “Transportation alone stands for more than 20% of emissions, so we focus on optimising the flows and decarbonising the unsustainable customer supply chain. We have a unique position in the market as we have a global footprint that no one else has. As such, reducing CO2 emissions can be leveraged on a global scale and that is a very strong proposition, appreciated by customers.”

“We are also looking into circular business models – 90% of products are shipped in one-way packaging which could be turned into reusable packaging. We already have circular business models based on track-and-trace systems or digital platforms and are building an infinity loop of packaging, where used packaging is collected to develop new solutions from the source itself. “

Continuing to Help Save Resources

Strict environmental principles are also applied to Nefab’s suppliers, said Mr Garrido. The company has a supplier validation scheme in place, assessing not only compliance with regulations but also their sustainable practices, such as materials sourcing.

“Customers now seek a one-stop-shop partnership, and that is what Nefab is set to offer. We have a new ERP (Enterprise Resource Planning) in place to support customer digital integration and invest in R&D and innovation in new materials. We will also continue to invest in production capacity, focusing on sustainable solutions such as fibre-based materials and recycled plastics.”

Speaking about the company’s prospects in the volatile markets of today, Mr Garrido says: “Many of our customers’ order books remain at a good level, hence we believe that in the long term, we will continue to have good demand.”

“We will continue to expand our footprint into new geographies – we have just concluded an acquisition in Switzerland and are looking for expansion in other markets. Sustainability brings challenges but also drives opportunities and we are well positioned to support customers in saving resources worldwide.”